Belt transmission type continuously variable transmission mechanism

A technology of infinitely variable speed and transmission, which is applied in the direction of transmission belts, transmission devices, mechanical equipment, etc., can solve the problems of small transmission torque, unbearable load, and easy damage of transmission belts, so as to reduce the loss between components and ensure reliable power transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

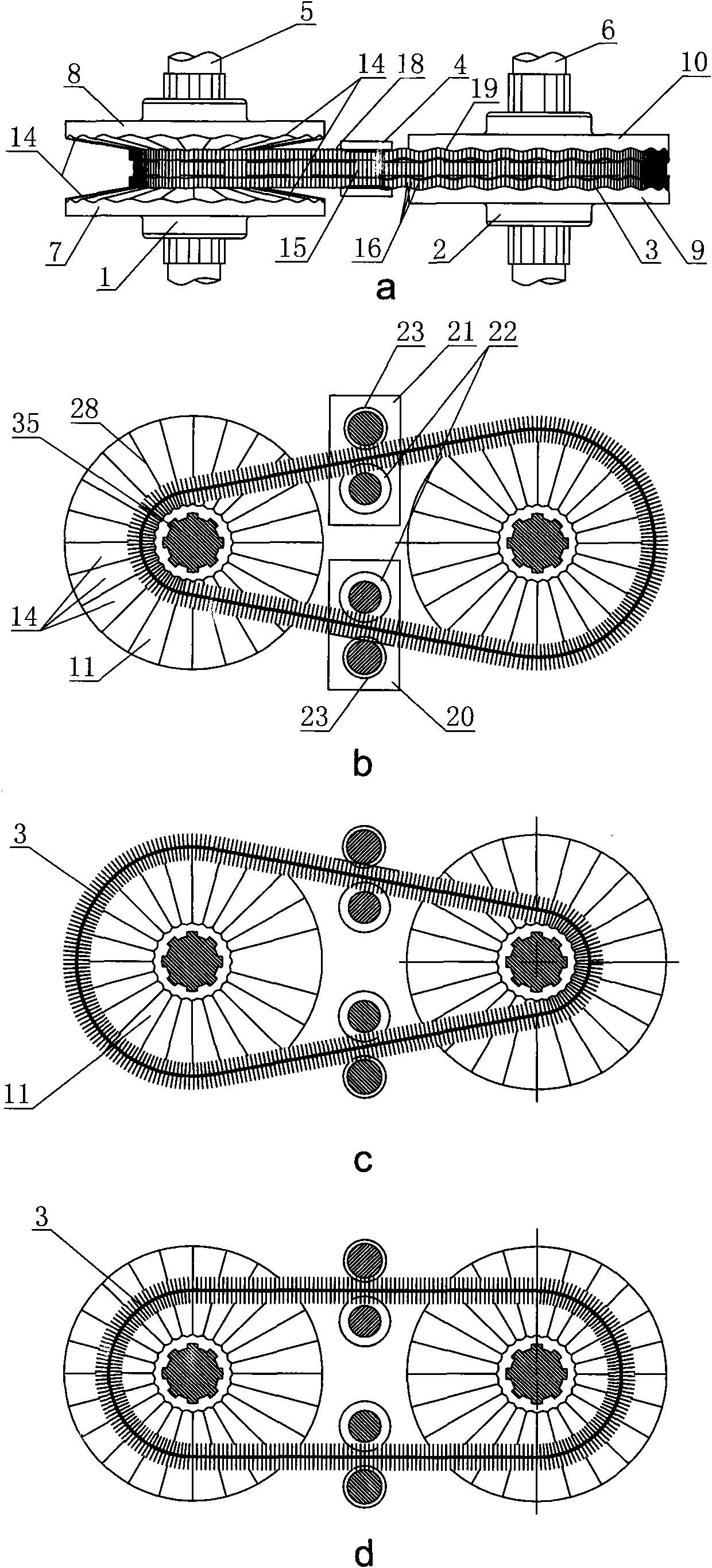

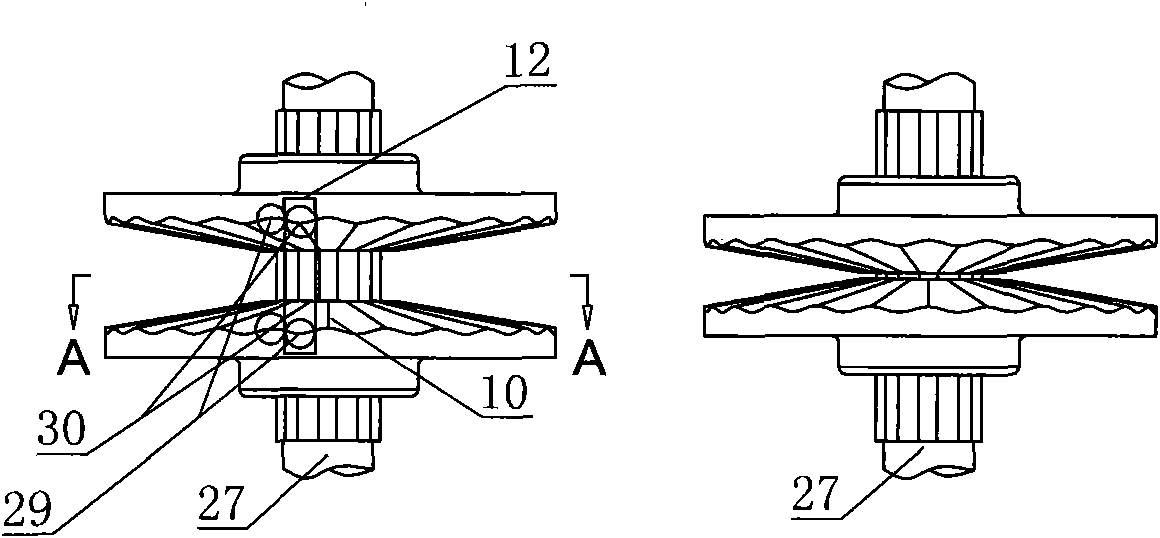

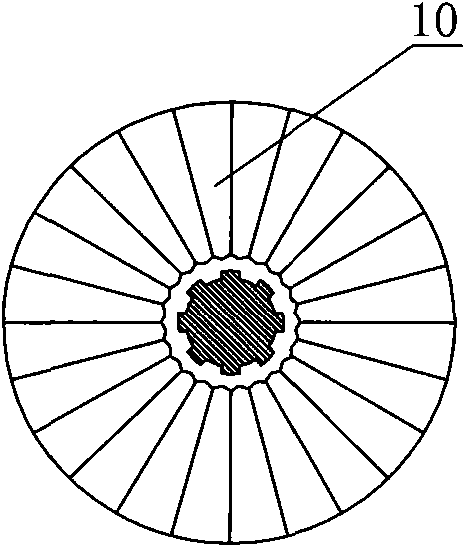

[0019] Mechanism of the present invention is further illustrated by a non-limitative embodiment provided by the accompanying drawings, referring to the accompanying drawings: the belt drive type stepless speed change mechanism among the figures, including the drive pulley 1 keyed on the input pulley shaft 5, the key The driven pulley 2 and the push-type transmission belt 3 connected on the output pulley shaft, the driving pulley is composed of the input shaft moving cone 7 and the input shaft fixed cone 8, and the driven pulley is composed of the output shaft moving cone The disc 10 and the fixed cone disc 9 of the output shaft are formed; the push-type transmission belt 3 is closed and wound in the V-shaped pulley groove 13 formed by the driving pulley and the driven pulley, by changing the axis of the moving cone relative to the fixed cone To the moving distance, drive the propulsive transmission belt 3 to rise or fall along the conical surface of the conical disc in the V-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com