Anti-bias DC burner

A burner, thick and thin technology, applied in the burner, combustion method, combustion type and other directions, can solve the problems of slow heating speed and high ignition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention should not be limited thereby.

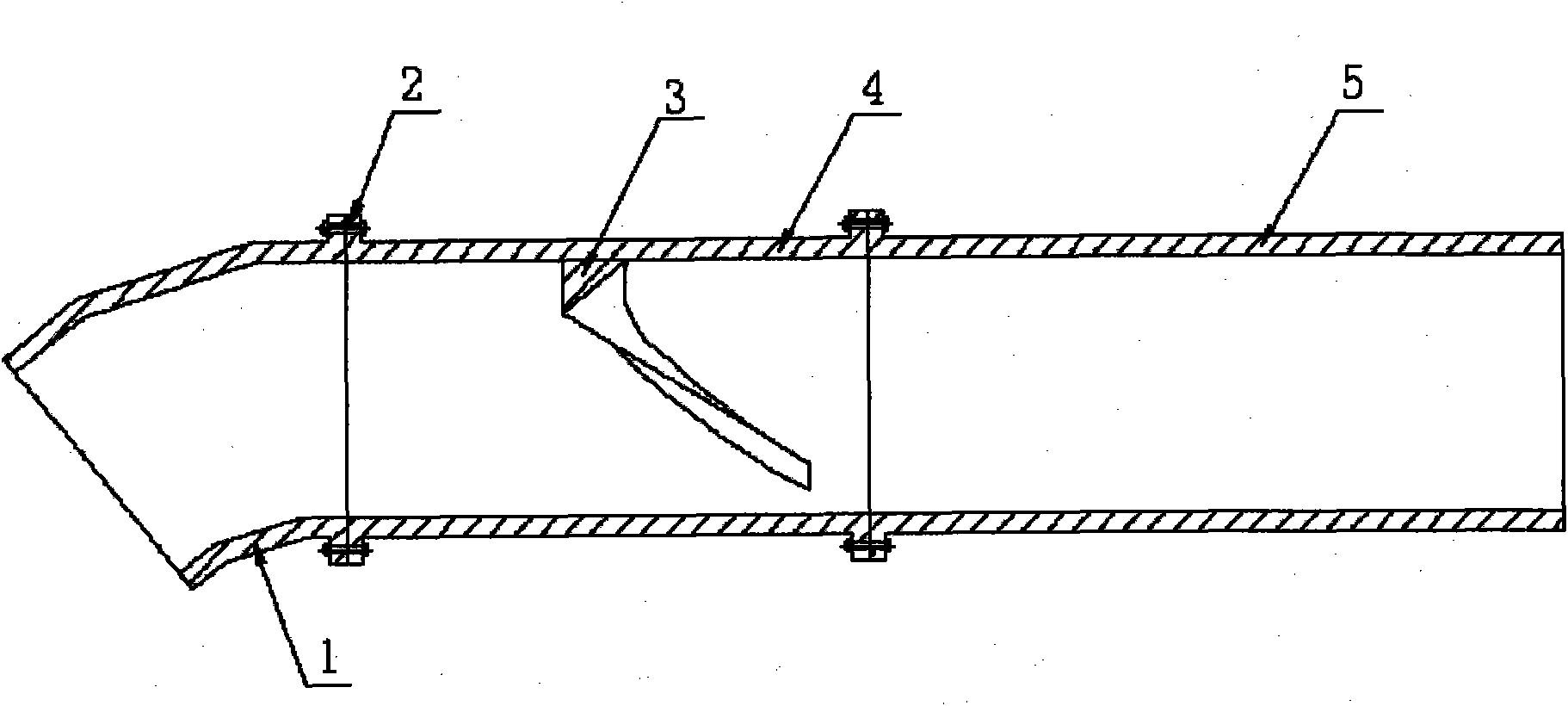

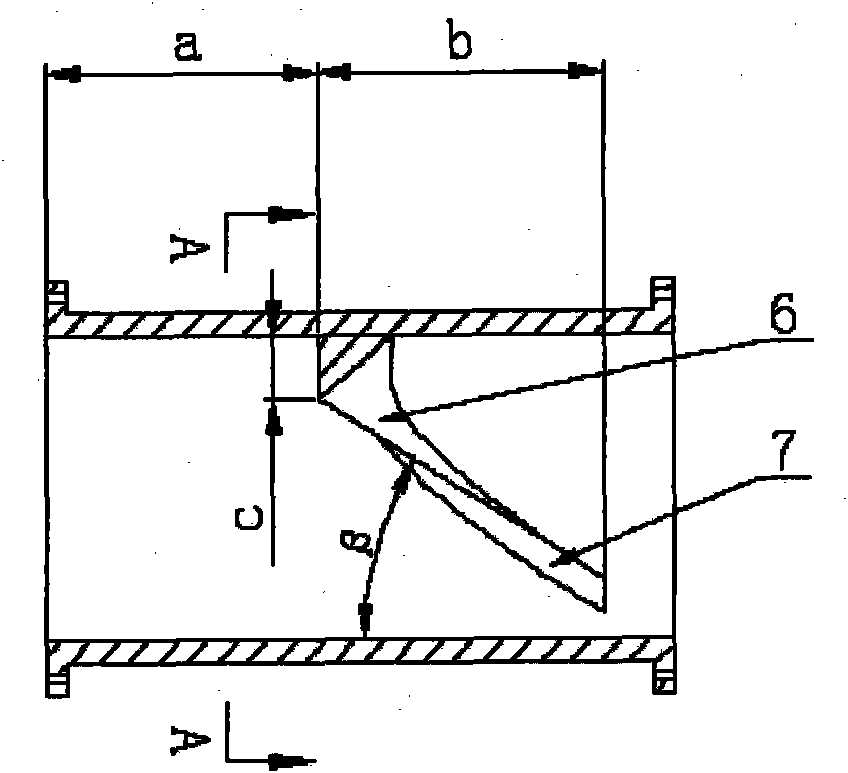

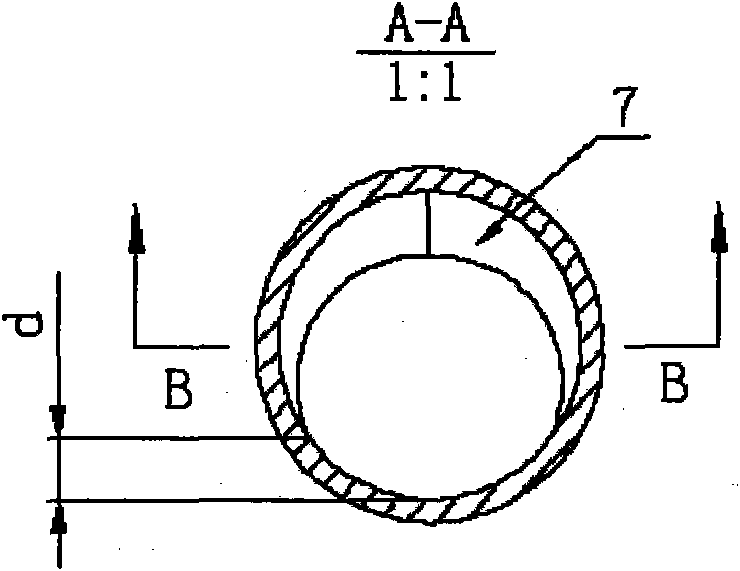

[0020] see figure 1 and figure 2 . The anti-concentration straight-line burner of the present invention, the burner includes a bend pipe connected in sequence, a diversion rudder tube section, and a nozzle section, the diversion rudder tube section has a diversion rudder, and the diversion rudder and the diversion rudder tube section form a Overall, the diversion rudder is shaped like the tip of a pen, with a sharp front end and then gradually stretches. The connections between the diversion rudder section, the elbow and the spout section are all flange connections. Ceramic tiles are evenly inlaid in the bend pipe, and the diversion rudder pipe sections are all wrapped by ceramic tiles, and the diversion rudders are also all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com