Method for measuring cavity surface temperature of semiconductor laser

A temperature measurement and semiconductor technology, which is applied in the field of semiconductor laser cavity surface temperature measurement, can solve problems affecting laser performance and detection effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

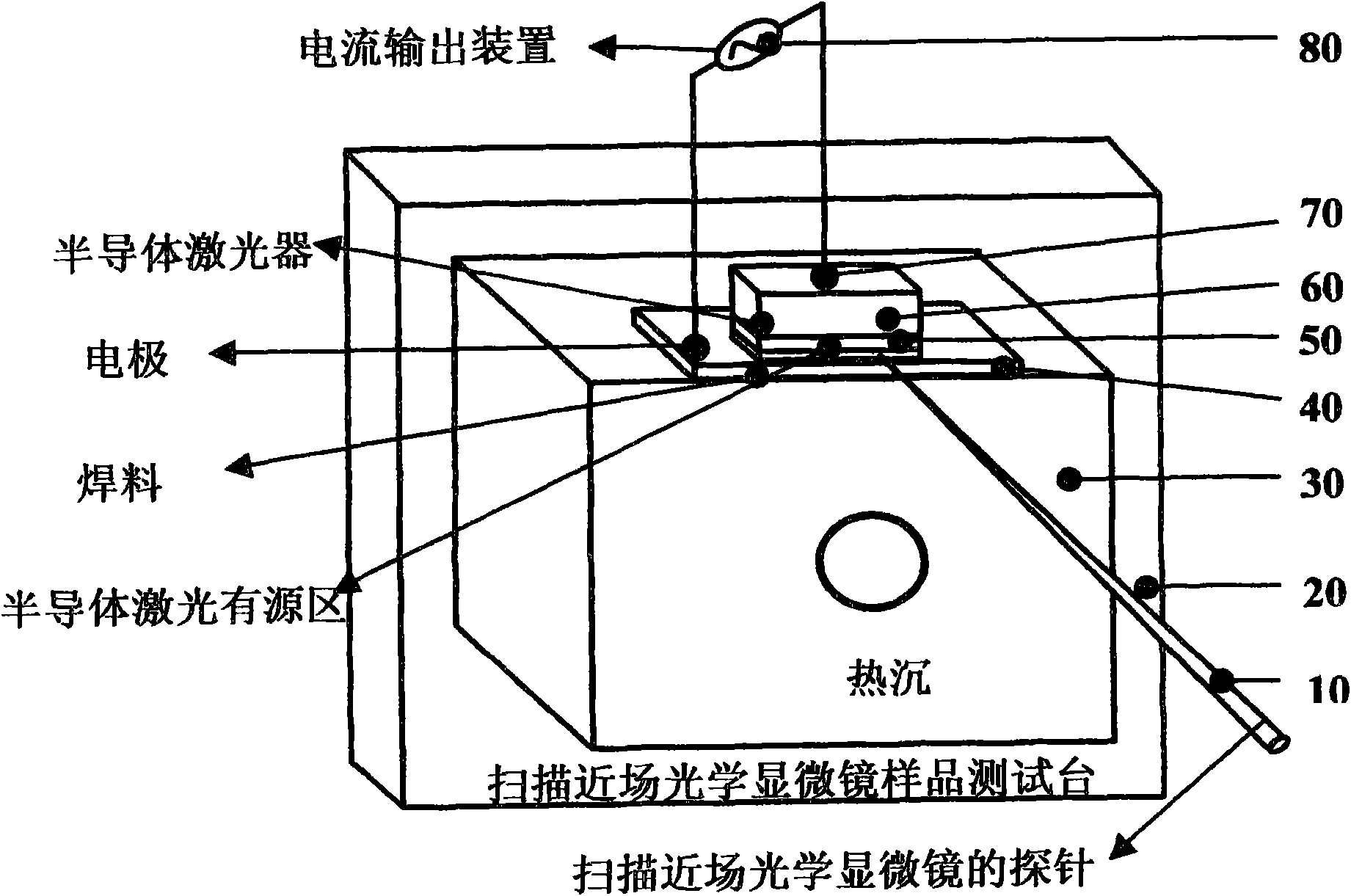

[0030] Example description: common 808nm wavelength edge emitting laser cavity surface temperature measurement.

[0031] in:

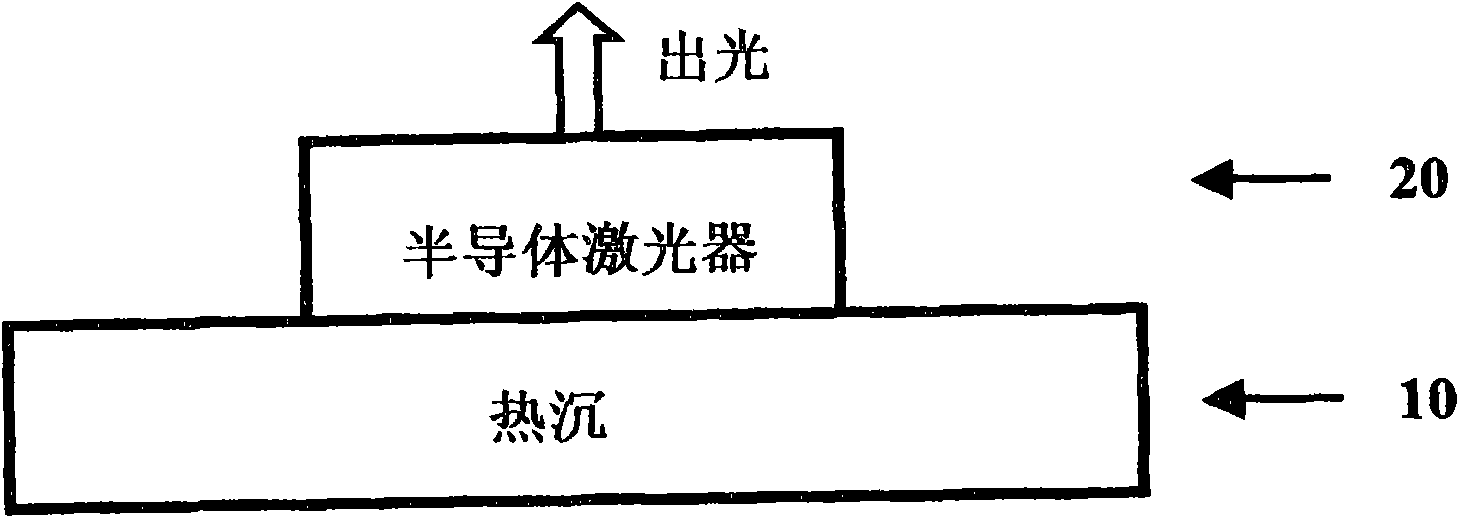

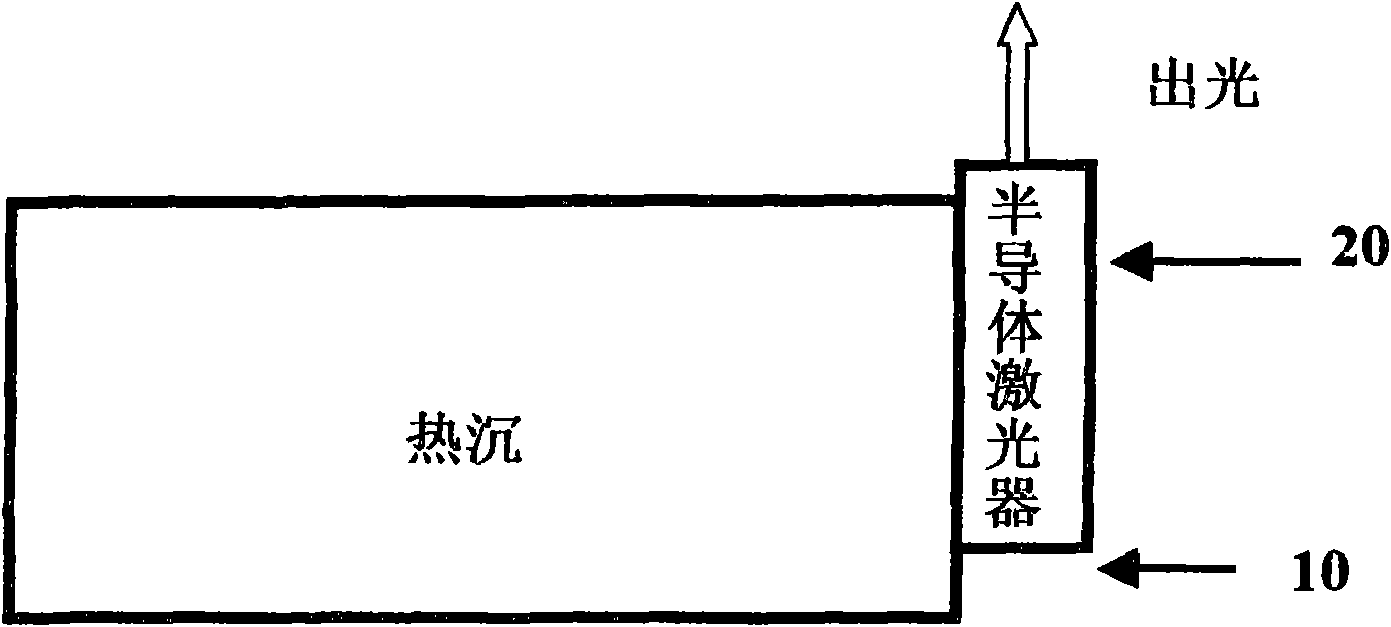

[0032] (1) Install the semiconductor laser 60 on the heat sink 30, and lead out the electrode 70; the heat sink 30 adopted in this example is a copper heat sink, and there is a circular through hole on the copper heat sink 30 for fixing. The copper heat sink has the faces with circular holes as the upper and lower sides of the heat sink 30, and the other faces are the sides of the heat sink 30 (see figure 1 ). This test method is suitable for surface-emitting semiconductor lasers 60 and edge-emitting semiconductor lasers 60. In order to enable the heat sink 30 with semiconductor lasers 60 to be easily installed on the scanning near-field optical microscope sample test stand 20, for surface-emitting and edge-emitting There are differences in the position where the semiconductor laser is mounted on the heat sink. For the surface-emitting semiconductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com