Ring-opening silicon substrate pressure sensor thick film circuit

A pressure sensor and thick film circuit technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of sensor accuracy loss, low production efficiency and reliability, and discontinuous resistance value, so as to ensure the insulation resistance and Improvement of dielectric strength, appearance quality, and expansion of compensation temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

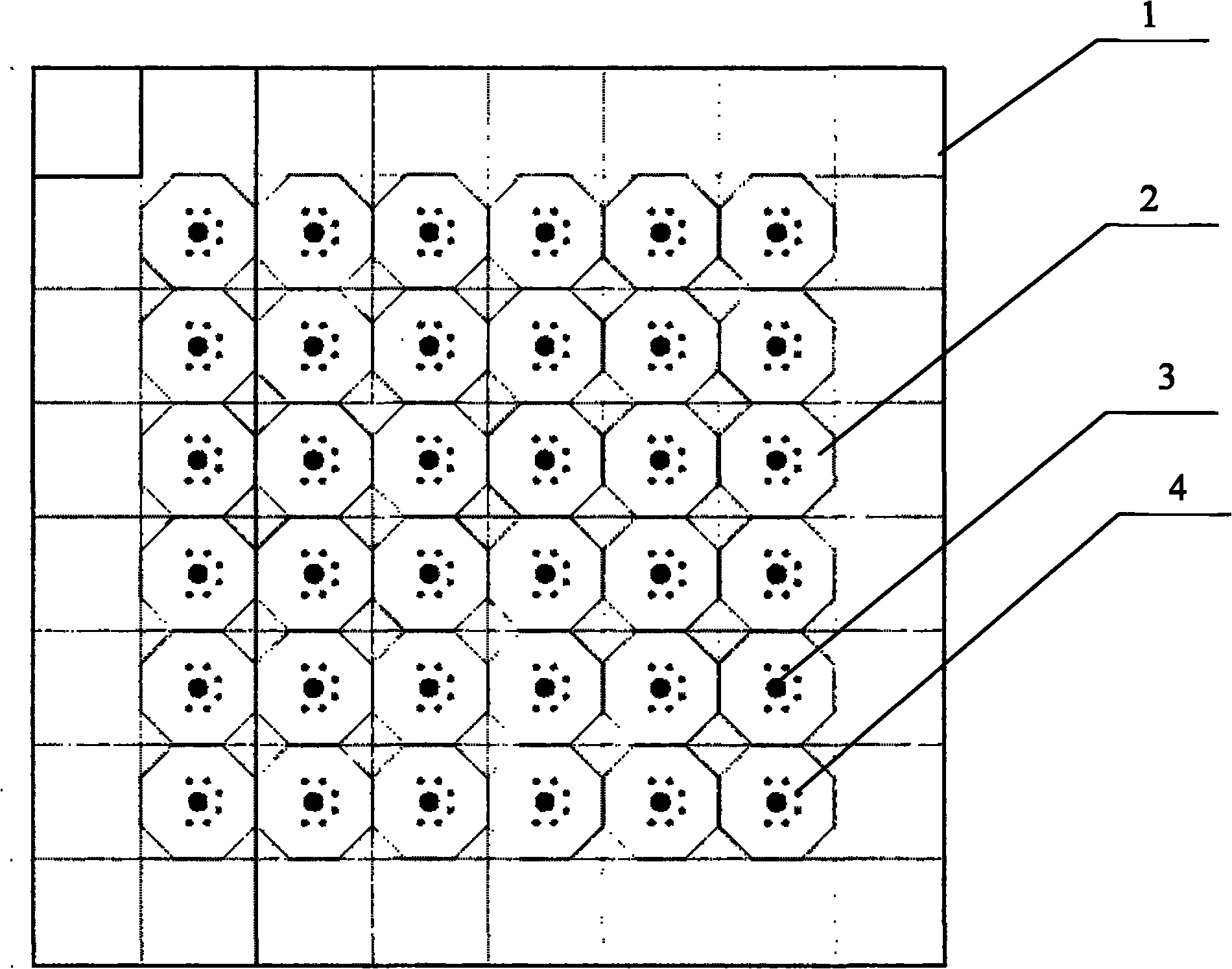

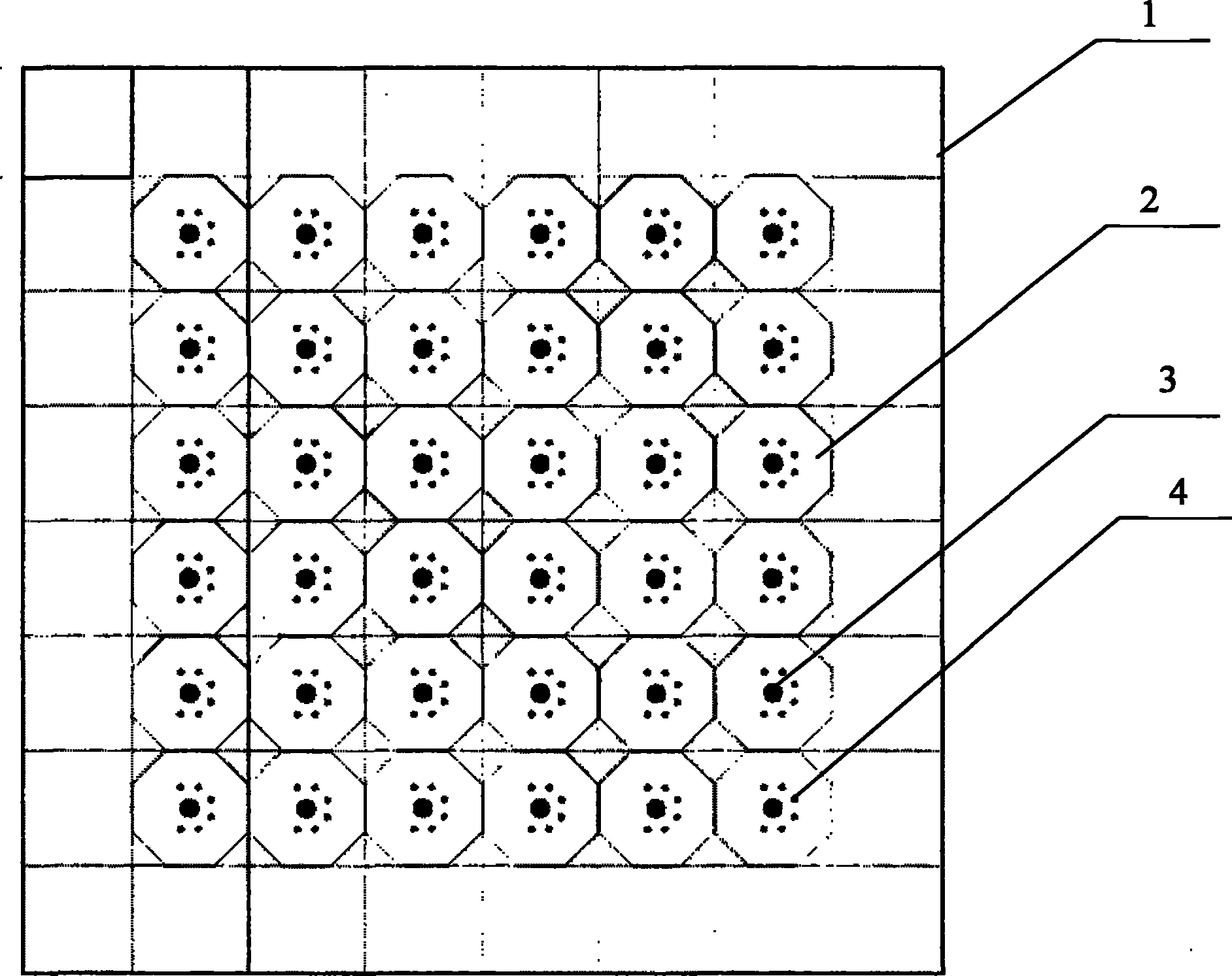

[0012] like figure 1 As shown, the thick-film circuit for temperature compensation and calibration uses a 4×4-0.025-inch ceramic substrate 1 as a substrate. In order to be suitable for mass production, the ceramic substrate 1 adopts laser pre-scribing technology, and each substrate is divided into 6× An array of 6, cut into 2 of thirty-six compensating plates. Each compensation plate 2 is designed with an assembly hole 3 according to the requirements of the packaging form. The shape of the compensation plate 2 is designed to be a regular octagon, and the outer diameter of the octagon is suitable for packaging. The assembly hole 3 on the compensation plate and the four non-adjacent sides are cut through with a digital positioning laser. A detection pin hole 4 is arranged around the assembly hole 3 , and a circuit is printed or laser etched on the compensation plate 2 . In order to insulate and isolate from the outside world, the compensation plate 2 is also coated with a glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com