Substrate structure and manufacturing method thereof

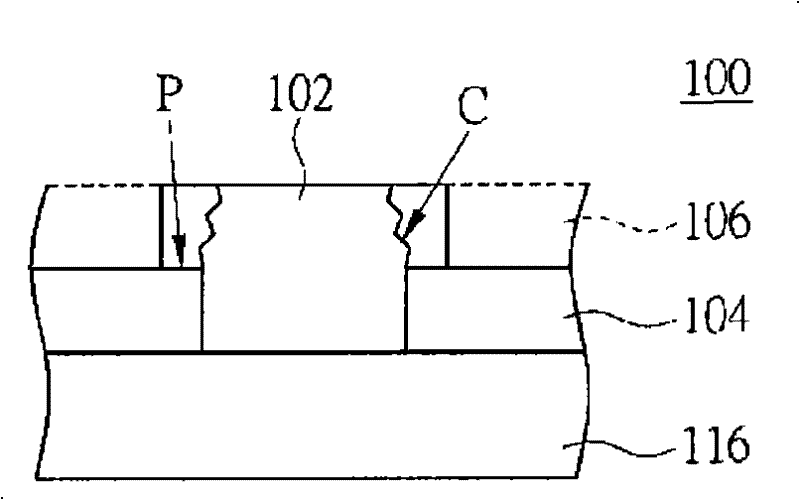

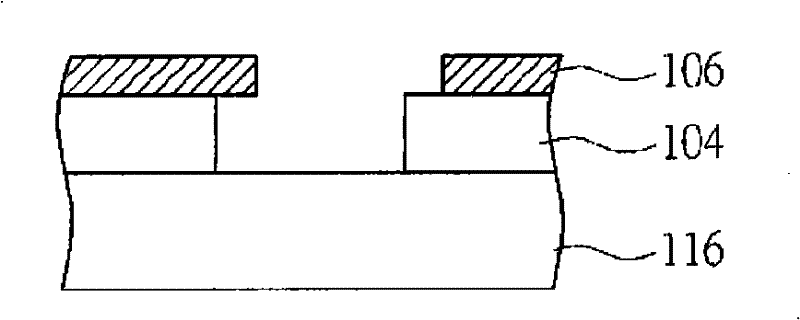

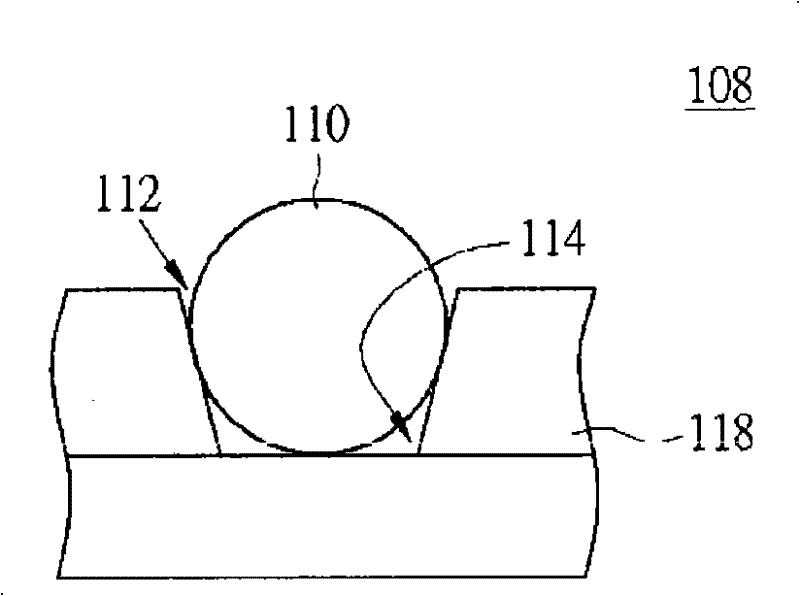

A manufacturing method and substrate technology, which are applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve problems such as the inability to fill the corners 114 and affecting the electrical connection quality of the solder balls 110.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Please refer to figure 2 , which shows a substrate structure according to a preferred embodiment of the present invention. In this embodiment, a substrate structure 100 suitable for flip-chip chips is taken as an example for illustration. The substrate structure 200 includes a base material 202 , a first insulating layer 204 , a conductive portion 206 , a second insulating layer 208 , a first seed layer 210 and a conductive layer 212 .

[0026] The substrate 202 has a first circuit layer 214 and a second circuit layer 216 respectively formed on opposite sides of the substrate 202 and the substrate 202 also has a via (Via) 220 as the first circuit layer 214 and the second circuit layer 216 electrical connection channels. In addition, the first insulating layer 204, such as green paint, is formed on the first circuit layer 214, the first insulating layer 204 has a first insulating layer opening 224, and the first insulating layer opening 224 is on the outer surface of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap