Magnetic valve

A valve seat and double valve technology, applied in the field of magnetic valves, can solve the problems of miniaturization difficulties, reduction of structural space of fluid joints and electrical joints, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

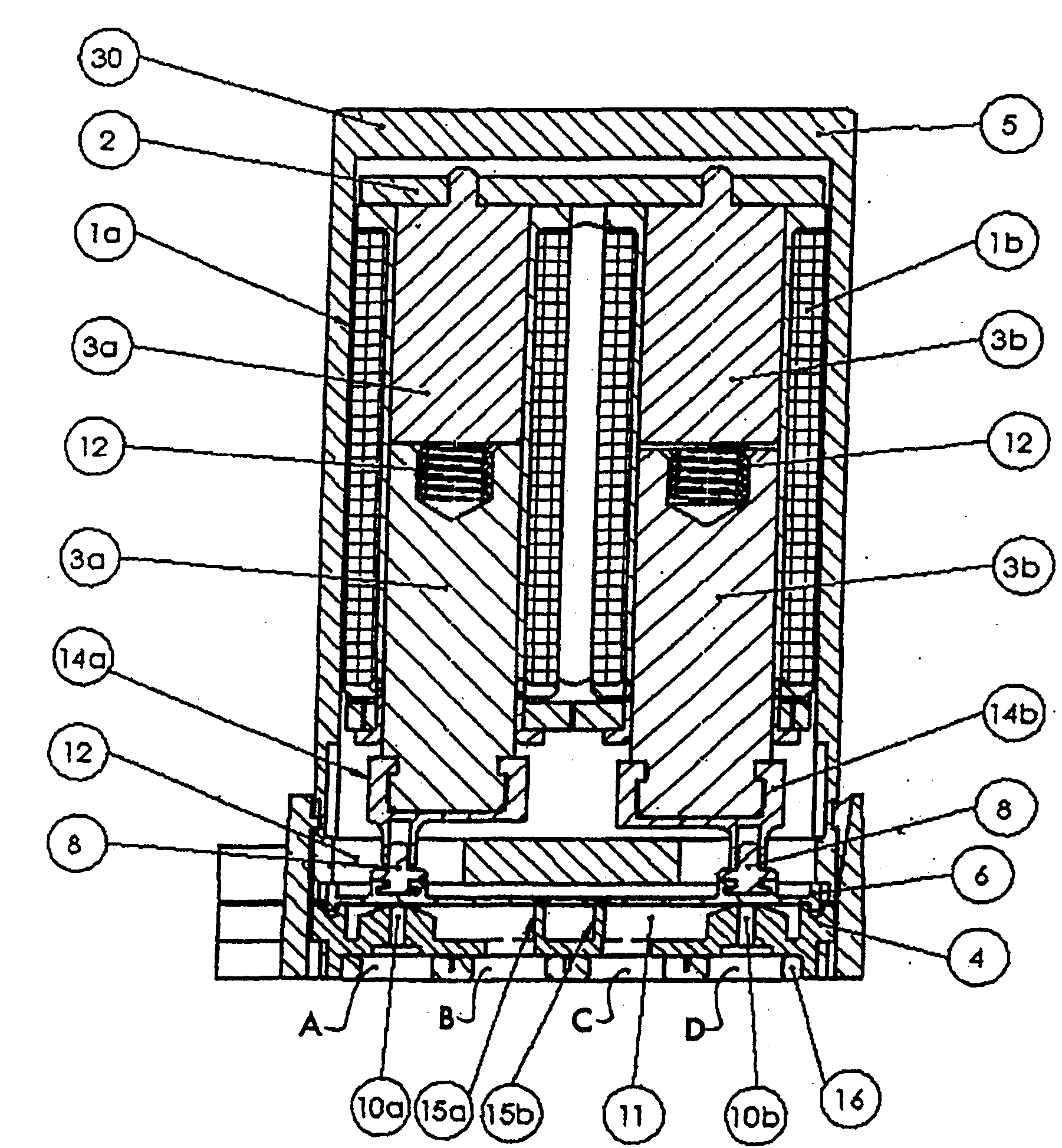

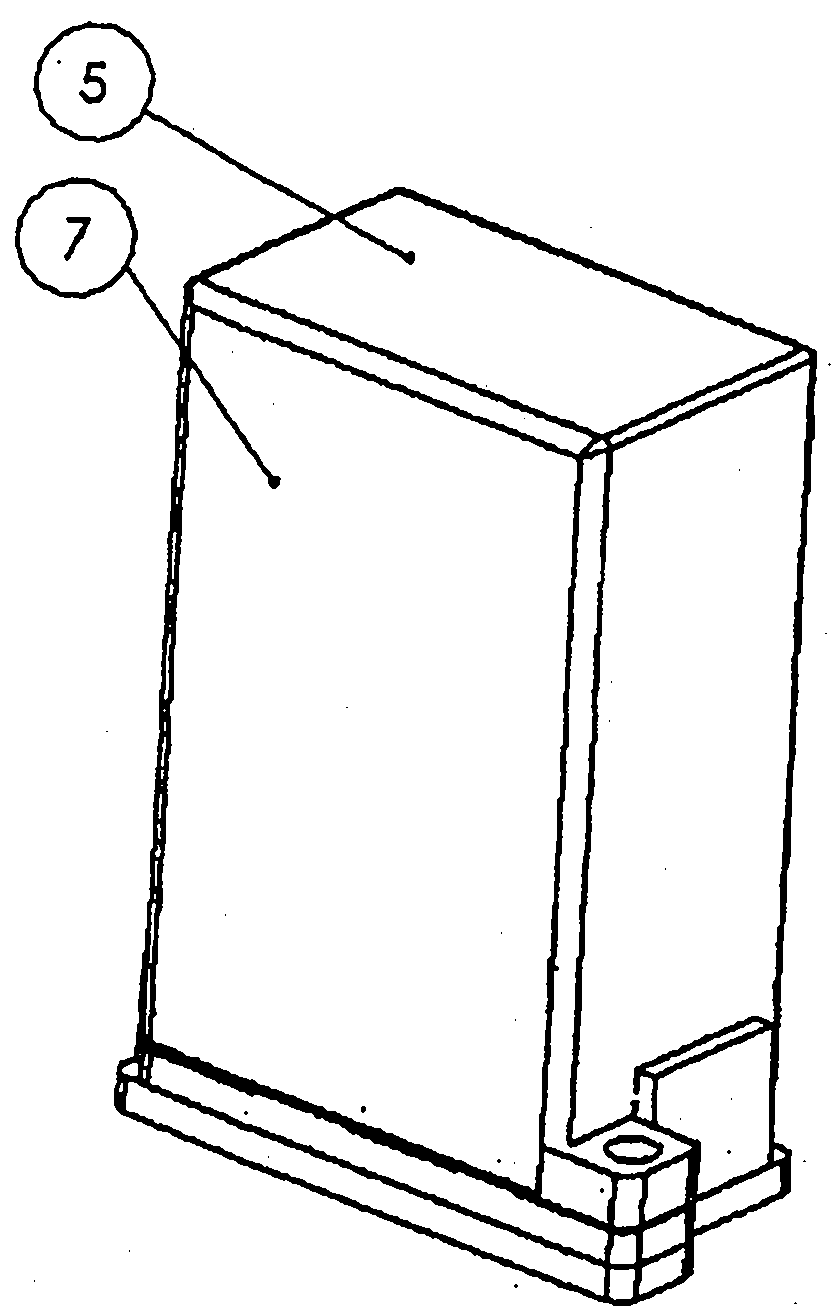

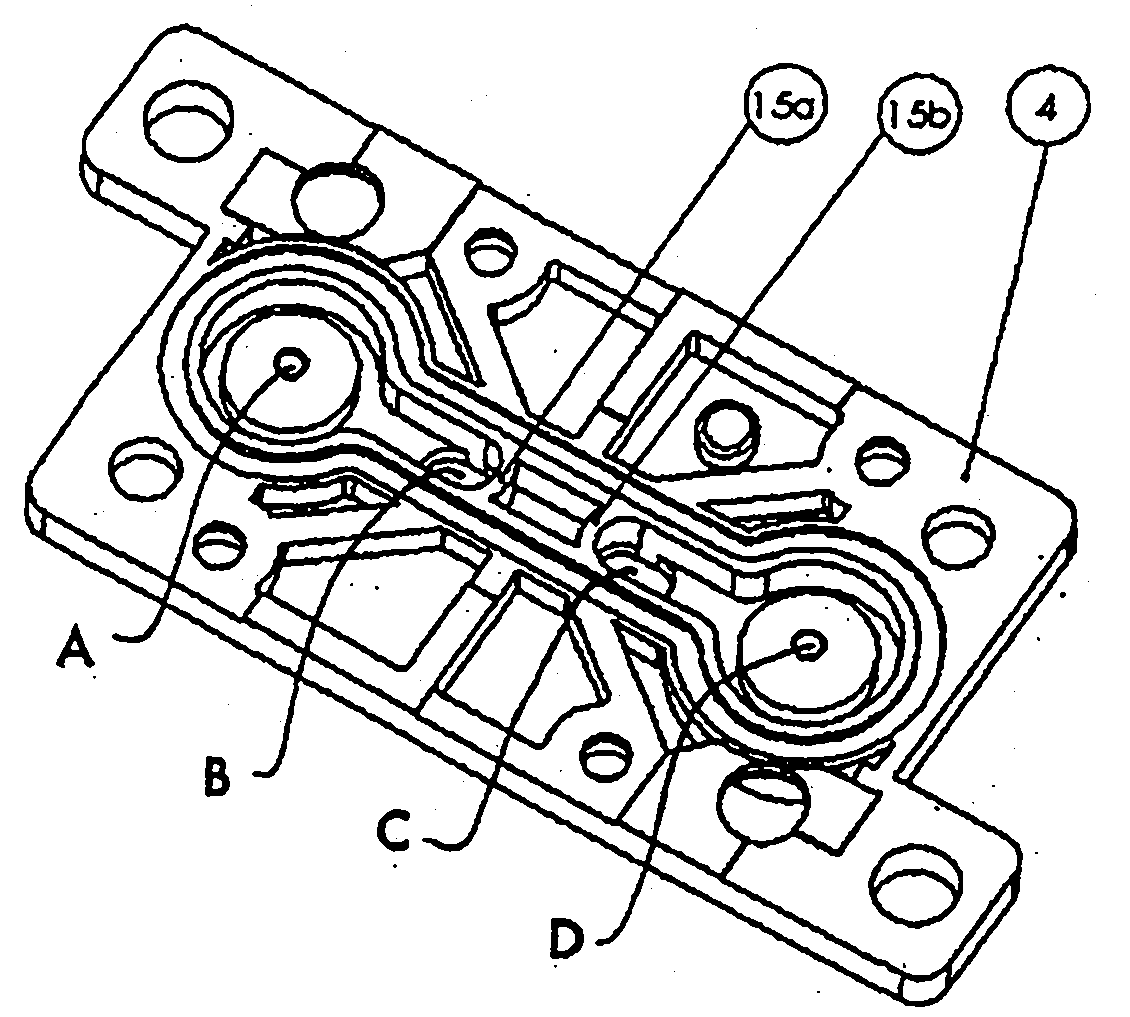

Embodiment Construction

[0025] In the compound valve according to the invention, not only the fluid and electrical connections, but also the other valve internal parts of both valves are assembled in one housing. This results in a very compact construction of the valve and an additional cost savings due to the common components—valve housing, diaphragm, magnetic circuit, electrical connections, coil casing—that are shared by both valves. The dual valve is compatible with known three-way valves not only in terms of external dimensions but also in terms of fluid connections and electrical connections, so that the two valve types can be easily combined with one another in the system. In another embodiment of the dual valve, the fluid components of the two valves are connected, although the two drives of the valves can be connected independently of one another. This results in a three-way valve with three possible switching positions: two valve seats closed; one valve seat closed and one valve seat open;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com