Method for forecasting temperature of slab of hot rolling heating furnace

A technology for heating furnaces and slabs, applied in temperature control, heat treatment furnaces, furnaces, etc., can solve the problems of cumbersome and complex calculations, and achieve the effects of simple calculation process, enhanced extensiveness, and improved forecasting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

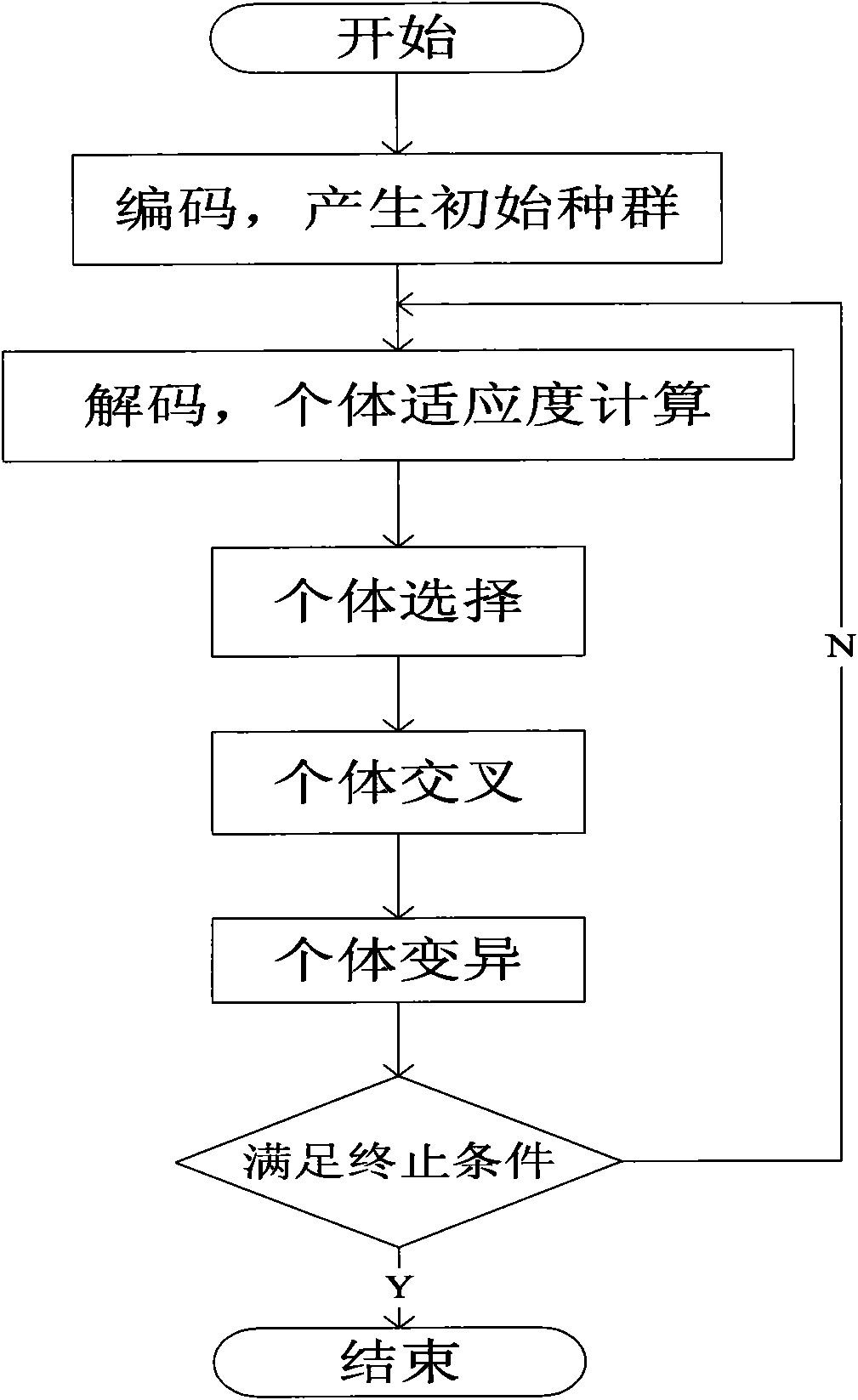

[0037] The method of the invention mainly predicts the heating curve of the billet in the furnace and the temperature out of the furnace through intelligent optimization.

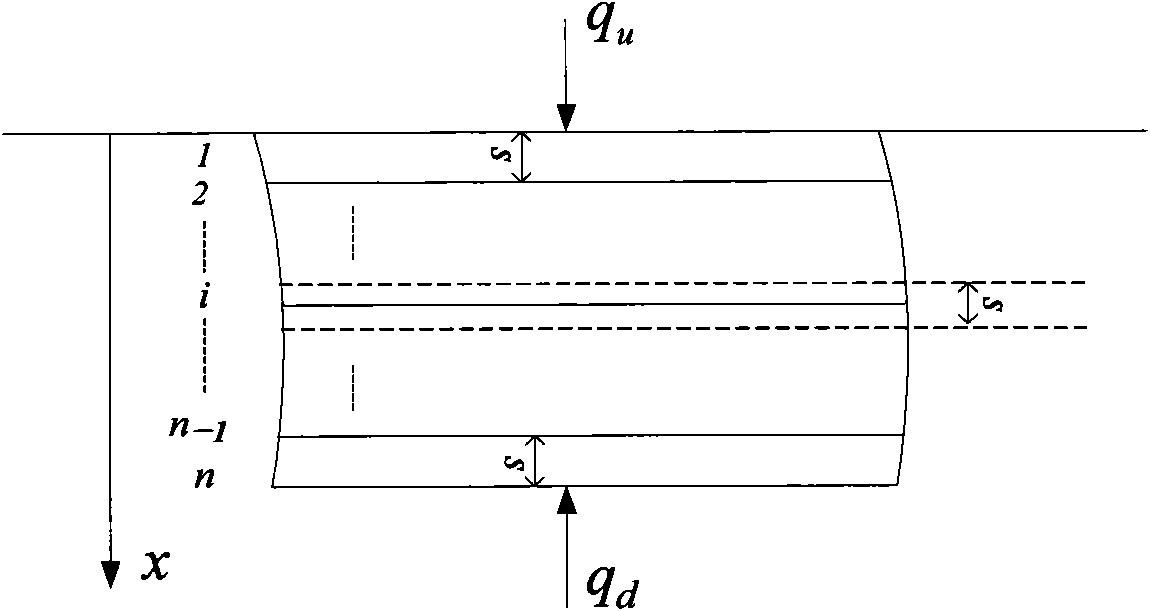

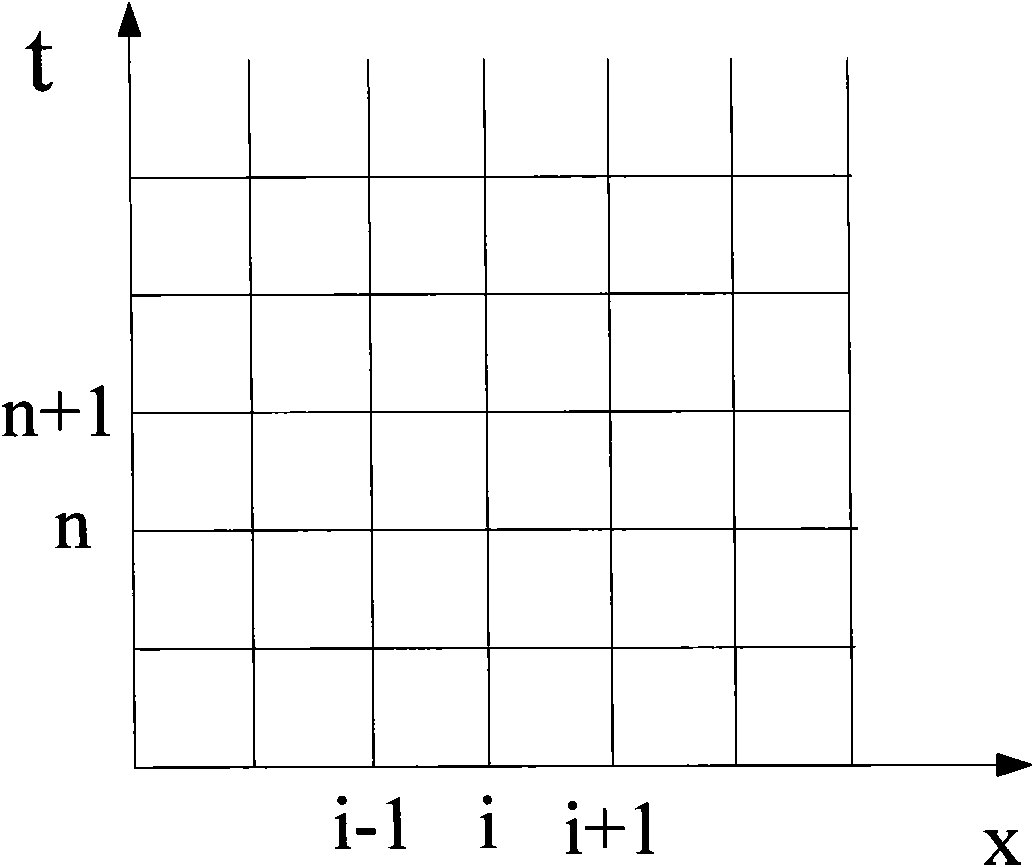

[0038] Difference equations for one-dimensional unsteady heat transfer

[0039] ∂ 2 T ∂ x 2 = 1 a ∂ T ∂ τ (Formula 1),

[0040] Partial derivative of temperature versus time Forward difference quotient, second order partial differential quotient of temperature versus distance The central difference quotient yields the difference equation:

[0041] (Formula 2)

[0042] In formula 1, T represents the temperature value of the billet, x is the coordinate in the thickness direction, τ is the time coordinate, and a is the thermal physica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com