Intermittent rotation control mechanism for turntable

A control mechanism and turntable technology, which is applied to household components, household appliances, and other household appliances. It can solve the problems of complex parts replacement, high failure rate of direct meshing of large and small gears, and inaccurate rotation and positioning of the turntable. It achieves low failure rate, Easy replacement of accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

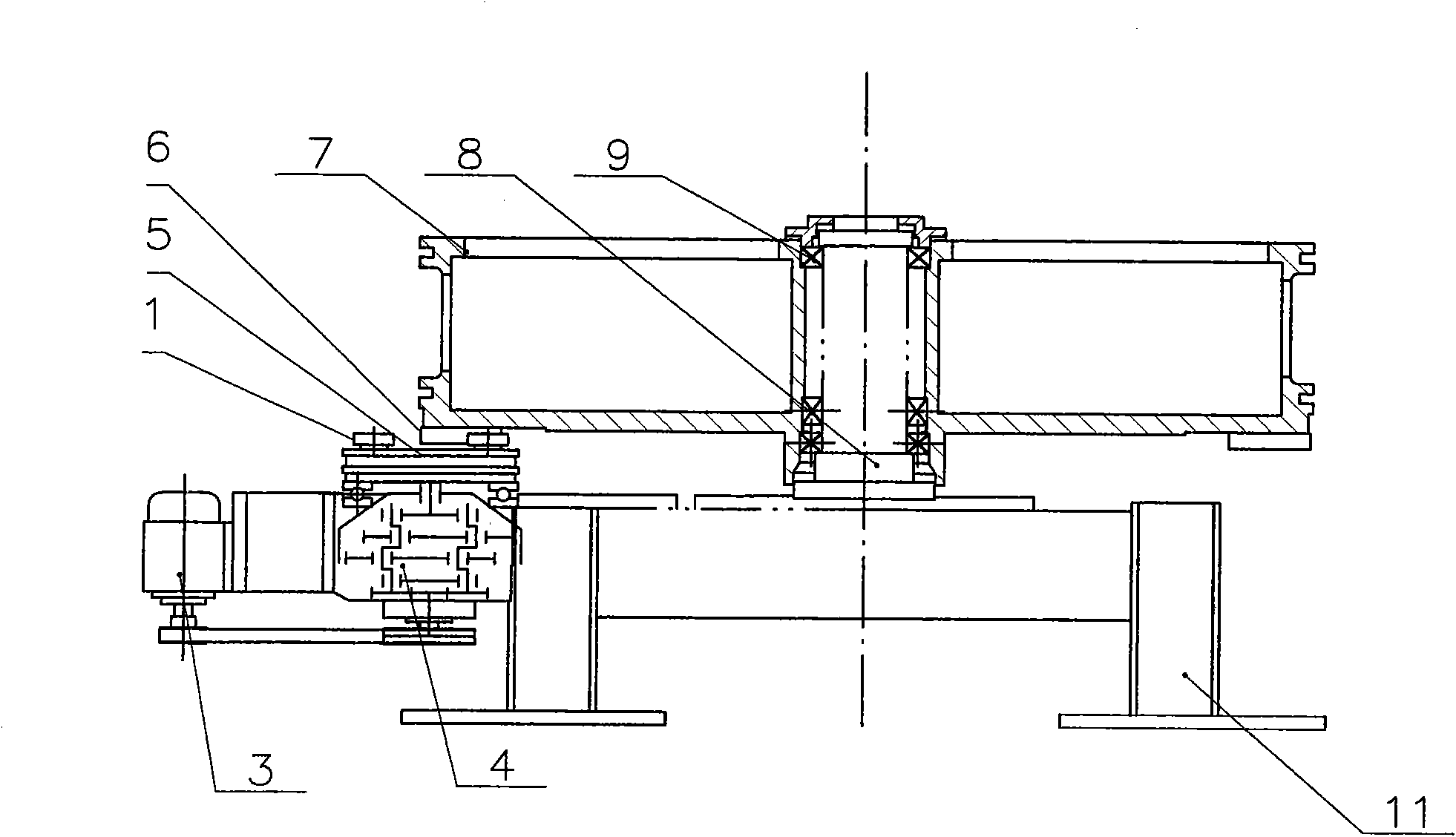

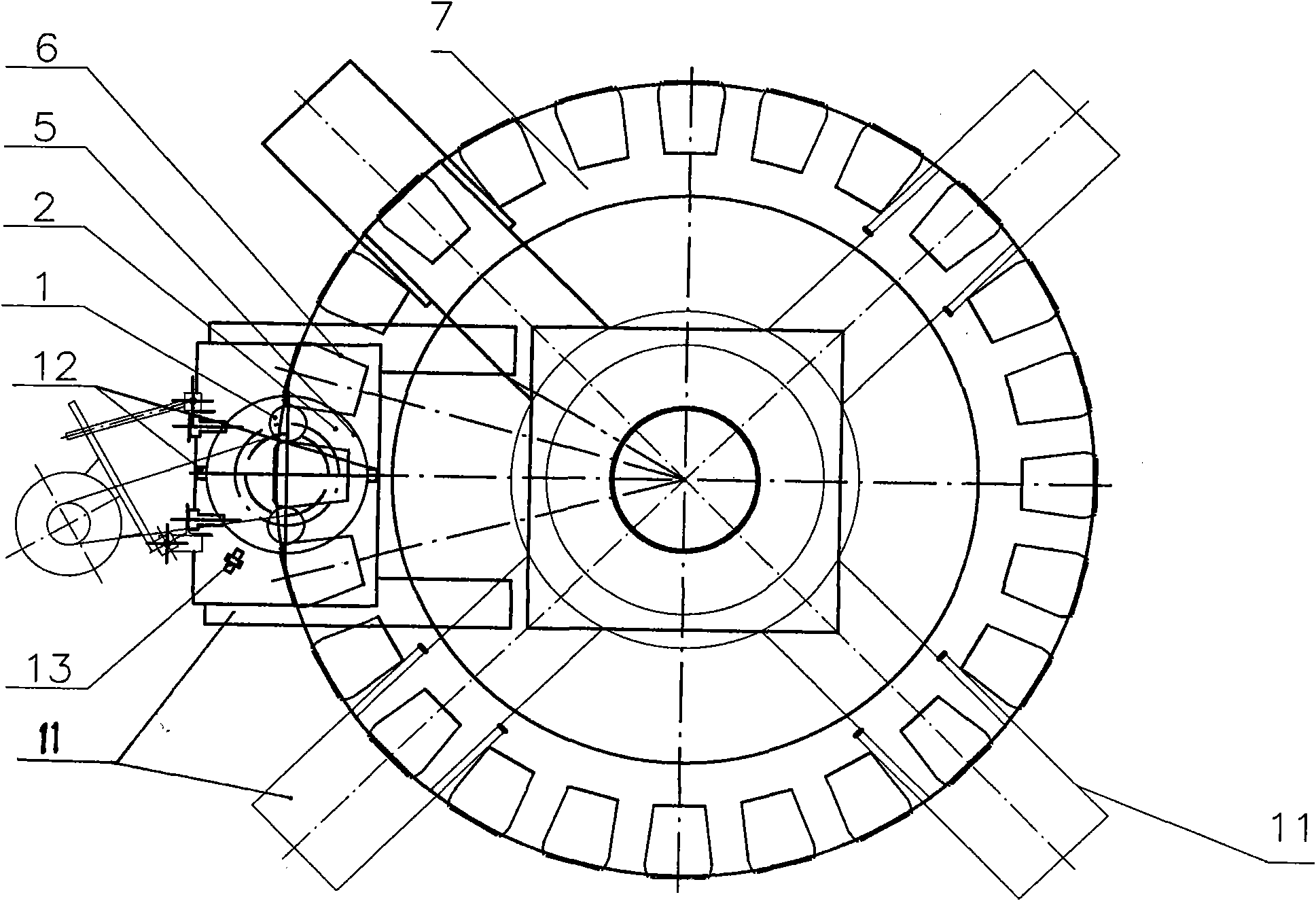

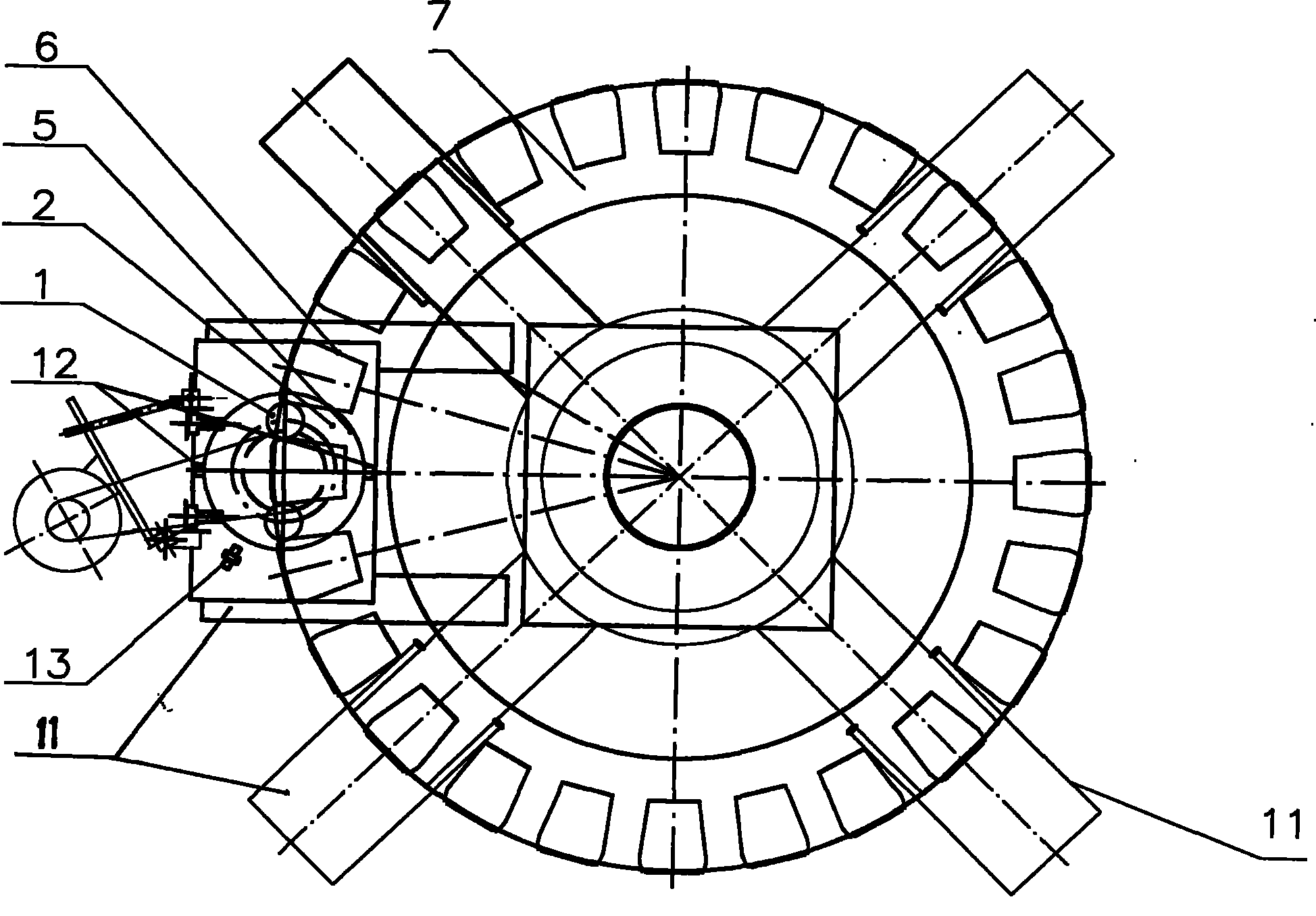

[0009] refer to figure 1 , figure 2 It can be seen that the present invention is applied to the intermittent rotation control mechanism of the turntable on the turntable type continuous side injection machine, including a motor 3, a reducer 4, a turntable 7, a turntable central axis 8 and a frame 11 (the motor 3 and the reducer 4 are mounted on the side of the frame On the side), said reducer 4 is provided with a dial 5, and two dials 1 are installed symmetrically on the upper surface of the dial 5; the lower surface of the turntable 7 is equipped with dials 6 that are consistent with the number of stations. (the dial corresponds to the position of the dial), the two dials can enter between the adjacent two dials respectively (i.e. the dial groove 2); on the rotating disk 5, and with the dial 1 An induction block 12 is also installed adjacently, and a sensor 13 corresponding to the induction block is also installed on the base 11 .

[0010] Among them: a bearing 9 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com