Production process of byproduct iron of thermal power plant and reduction kiln thereof

A technology for thermal power plants and production processes, which is applied in the petroleum industry, furnaces, furnace types, etc., can solve problems such as functional waste and the inability to use the reducing capacity of reducing substances reasonably, and achieves reduction of initial investment scale, iron smelting, etc. The effect of reducing energy consumption and cost, improving continuity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manner of the present invention will be described through examples and accompanying drawings.

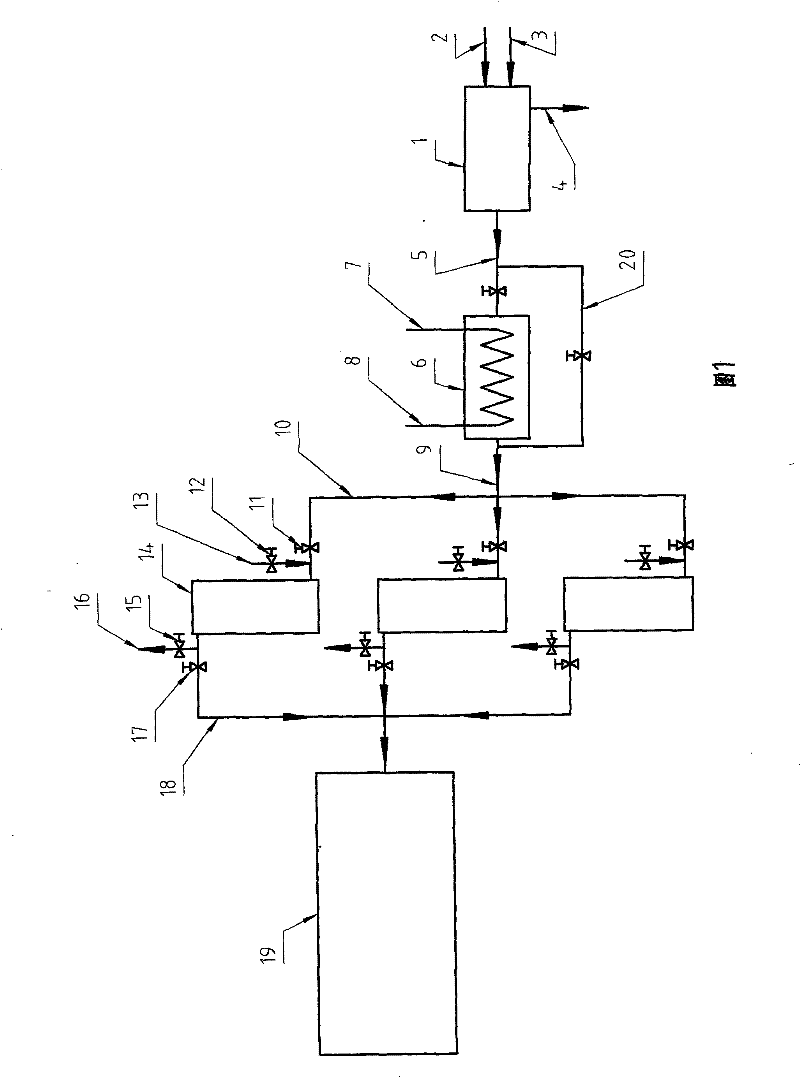

[0046] exist figure 1 In the shown embodiment 1, 1 is the coal gas generator, 2 is the inlet of the fuel coal of the gas generator, 3 is the air inlet of the gas generator, and 4 is the discharge channel of the fuel residue of the gas generator, 5 is the outlet of the gas produced by the gas generating device, 6 is the heat exchanger, 8 and 7 are the inlet and outlet of the heat exchange medium of the heat exchanger, and 9 is the outlet channel of the gas whose temperature meets the requirements after heat exchange , 10 is the branch passage of gas (it should be noted that there are 3 branch passages in the figure, only one branch passage is marked, and the rest are the same as this branch), 11 is the branch passage of gas on 10 12 is the switch valve on the scavenging passage 13, 14 is the reduction kiln, in this embodiment, it can also be calle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com