Portable optical cable identifying embedded hole boring device

A drill and portable technology, which is applied to the field of portable optical cable identification and burial drills, can solve the problems of long operation time, large operation area and high operation cost, achieve short operation time, small operation area, and avoid repeated construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

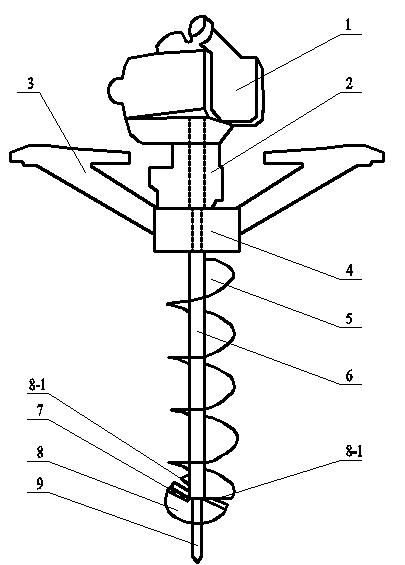

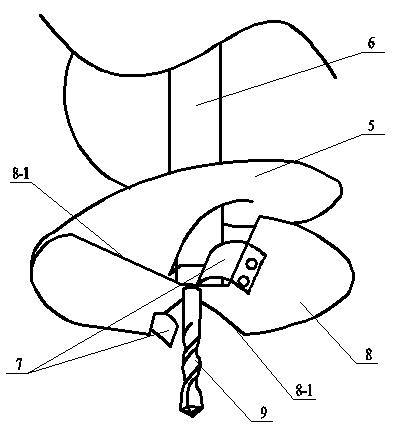

[0007] Specific implementation mode one: combine figure 1 with figure 2 Illustrate the present embodiment, the portable optical cable marking embedding drill of the present embodiment comprises gasoline engine 1, speed reducer 2, support seat 4, helical blade 5, drill rod 6, drill bit 9 and two handrails 3, the gasoline engine 1 The output end is fixedly connected with the input end of the reducer 2, and the lower end surface of the reducer 3 is fixedly installed with a bearing seat 4, and the upper end of the drill rod 6 is fixedly connected with the output end of the reducer 2 through the support seat 4, and the drill rod 6 is fixedly connected with the output end of the reducer 2. The lower end is fixedly equipped with a drill bit 9, and the helical blade 5 is fixedly connected on the wall of the drill rod 6, and the helical blade 5 is located between the support base 4 and the drill bit 9, and two handrails 3 are installed on the outer wall of the support base 4.

[0008...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 with figure 2 The present embodiment will be described. The drill 9 of the present embodiment is an alloy drill. So set, the service life is longer. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 with figure 2 The present embodiment will be described. The blade thickness of the helical blade 5 of the present embodiment is 2 mm to 5 mm. Such a setting prevents the deformation of the spiral blade and has a longer service life. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com