Ultrasonic measured and controlled water distributing device

A water distribution device, ultrasonic technology, applied in the direction of measurement, production fluid, wellbore/well components, etc., can solve the problems of large injection accuracy errors, complex deployment operations, high operating costs, etc., to achieve low efficiency, simple operation, and structure well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

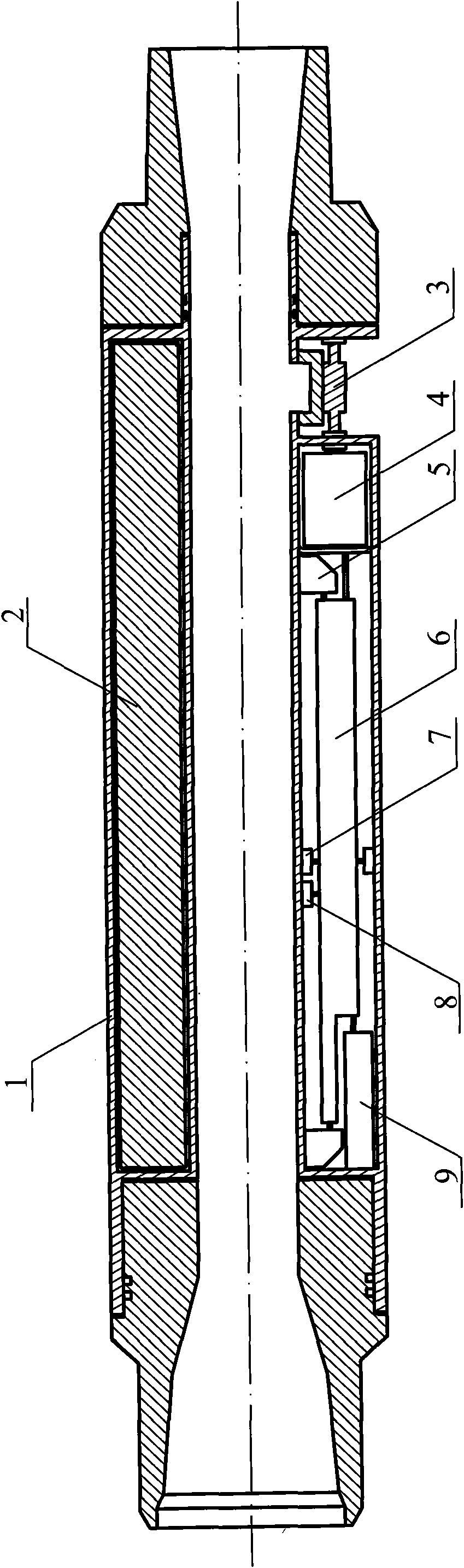

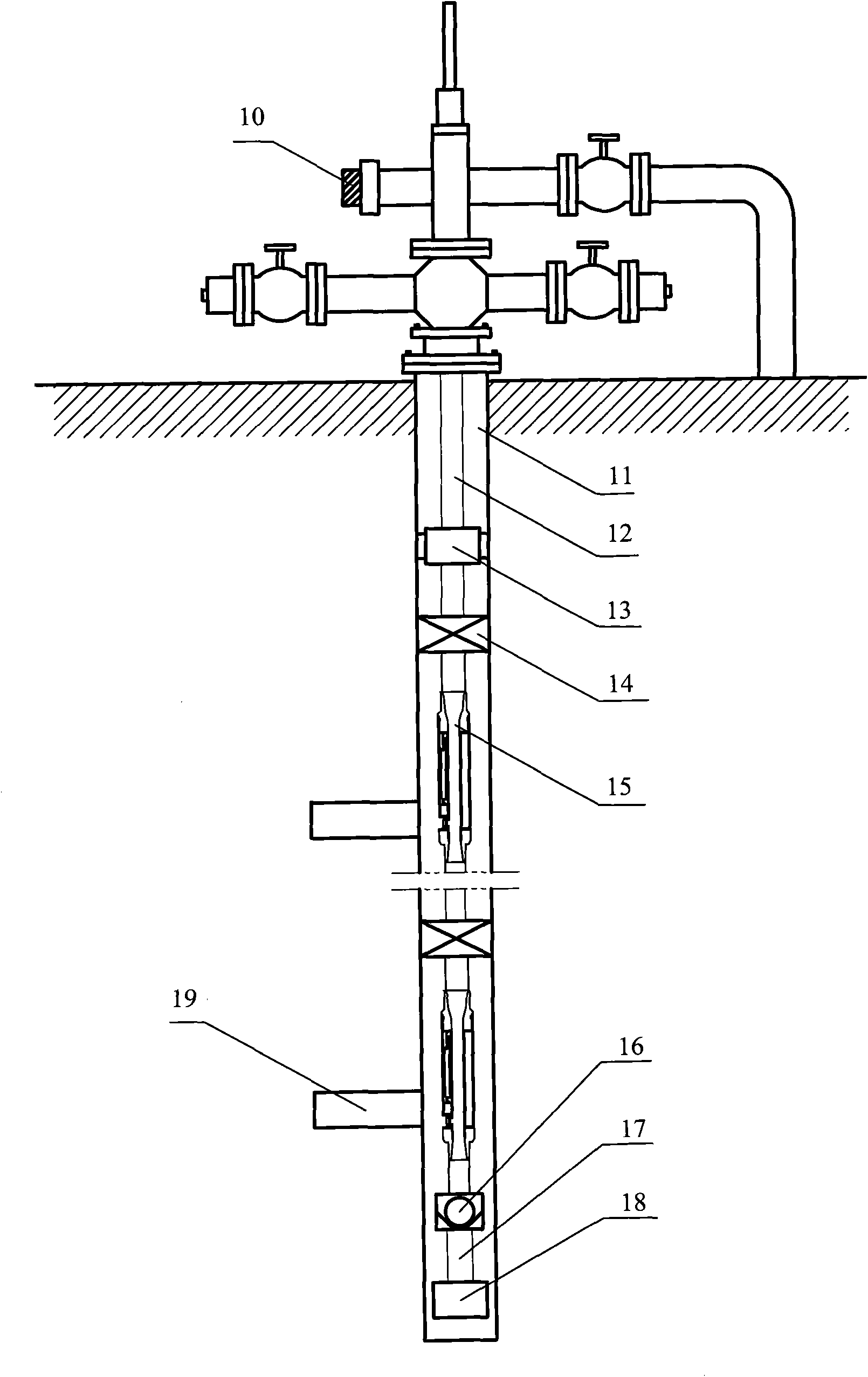

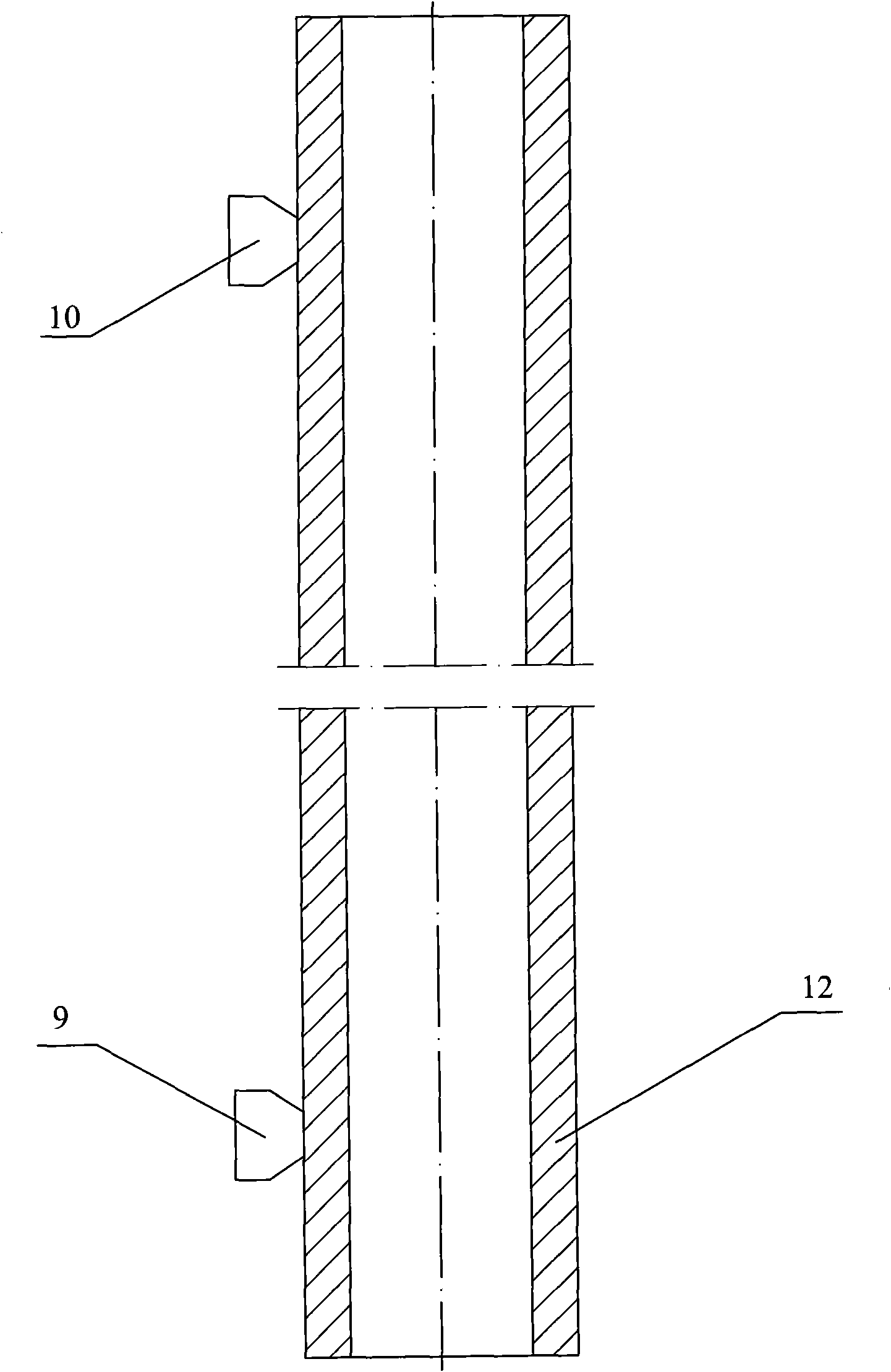

[0022] according to Figure 1~5 The specific structure of the present invention will be described in detail. The ultrasonic measurement and control water distribution device is improved on the basis of the existing layered water distribution method, which fundamentally solves the problems that the existing water distribution device can only send commands from the ground to the underground, and cannot communicate in two directions. it can be as figure 2 A water injection well with a plurality of water injection layers 19 is shown installed on site. The quantity of the water injection layer 19 should be selected according to actual use needs. The device includes a casing 11 provided with a plurality of water injection layers 19, centralizers 13 assembled in the casing 11 and sequentially connected together through metal water injection pipes 12, sealed in each water injection layer 19 with a water blocking packer 14 Ultrasonic testing and deployment of water device 15, ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com