Pitch adjusting system of rotation type hydraulic proportional servo drive motor

A servo-driven, rotary-type technology, applied in fluid pressure actuating devices, engines, wind turbines, etc., can solve the problems that the generator set cannot start power generation at any time, the system response speed is slow, and the control loop is complicated, and achieves high rigidity and dynamic performance. The effect of fast response and large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

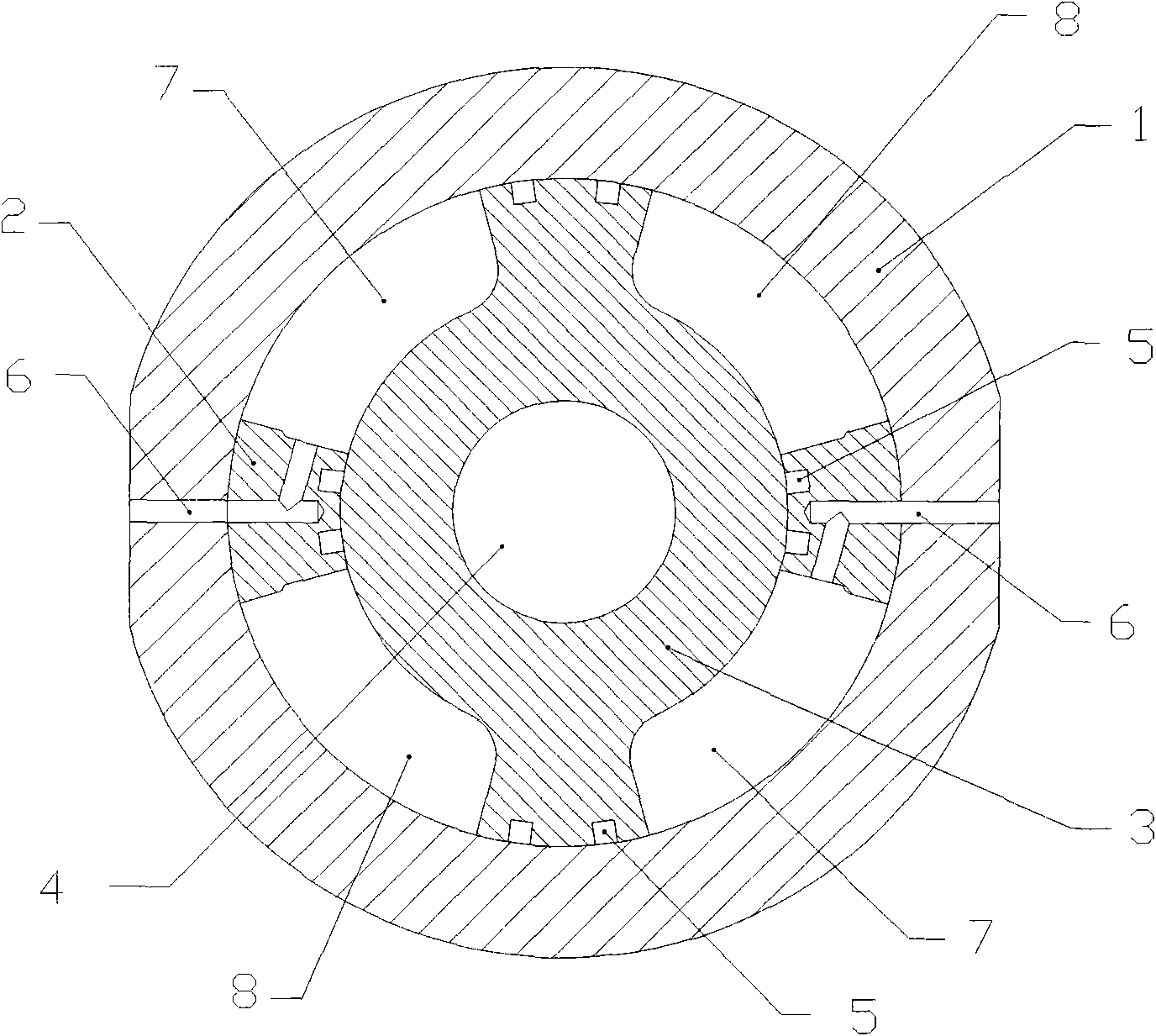

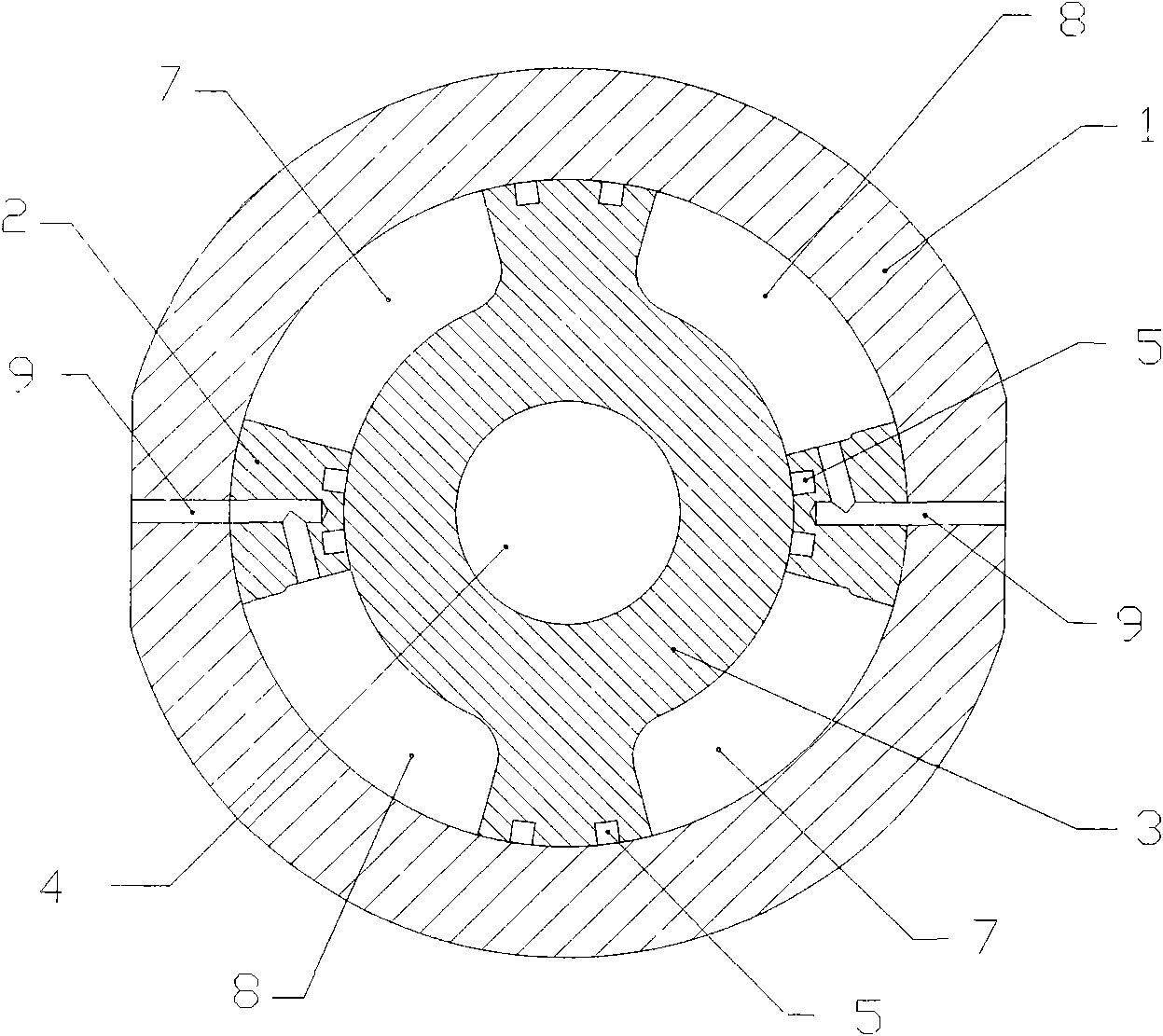

[0023] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

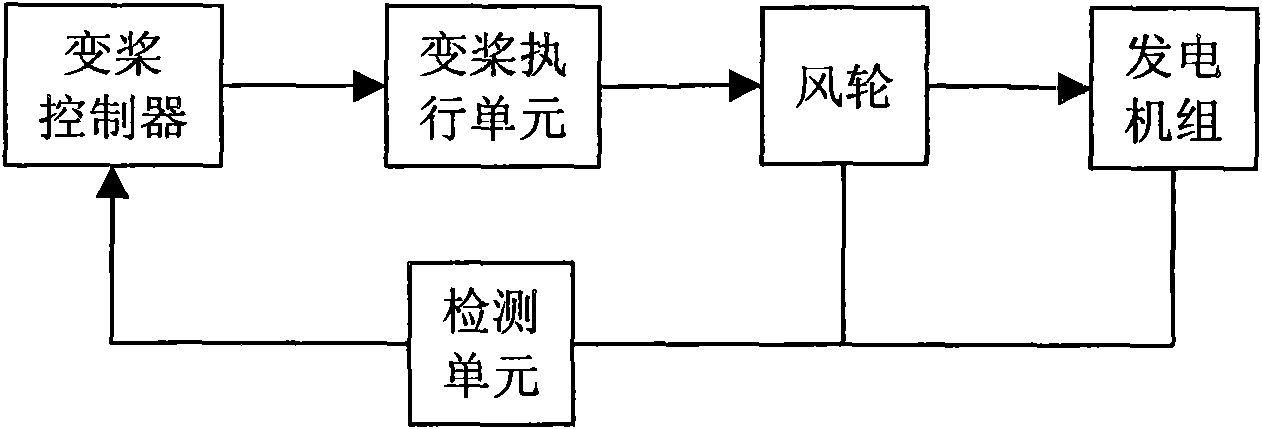

[0024] Such as figure 1 As shown, a rotary hydraulic proportional servo drive motor pitch control system provided by an embodiment of the present invention includes a wind wheel with blades, a generator set, a pitch controller, a pitch execution unit, and a detection unit. The pitch controller controls the operation of the pitch execution unit. The pitch execution unit is used to control the change of the pitch angle of the wind rotor. The wind rotor is connected to the generator set to drive the generator set to generate electricity. The detection unit is used to detect The pitch angle of the wind wheel and the power of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com