Lens cone and camera lens module thereof

A lens barrel and barrel body technology, which is applied in the field of lens modules, can solve the problems of large friction between the lens barrel and the lens base, burrs, and easy generation of chipping, so as to improve assembly accuracy and reliability, and reduce chipping. Possibility, effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

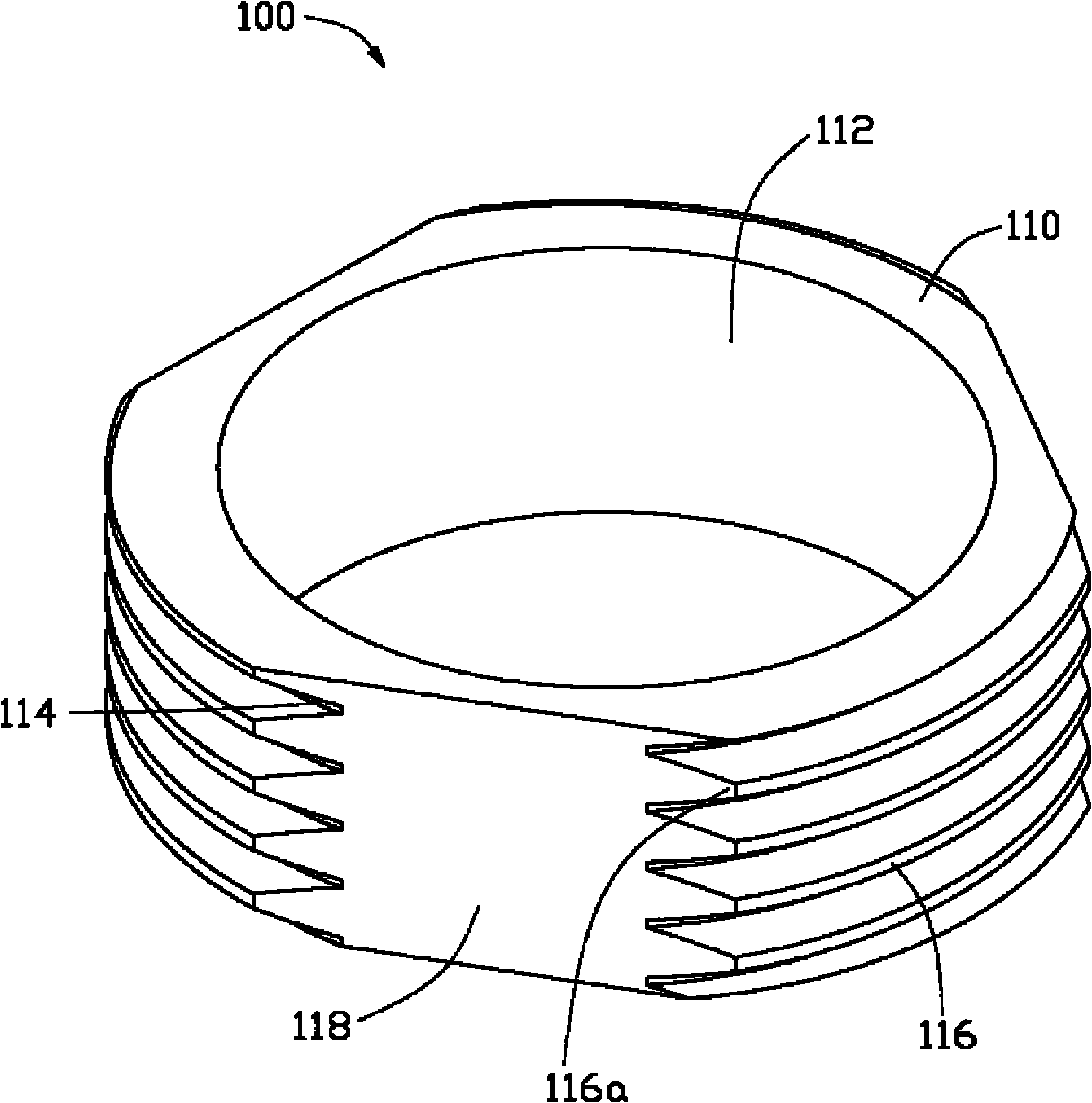

[0012] see figure 1 , a lens barrel 100 provided by the first preferred embodiment of the present invention. The lens barrel 100 includes a barrel body 110 , and the barrel body 110 is in the shape of a hollow cylinder and includes an outer side surface 112 and an inner side surface 114 . An external thread 116 surrounding the barrel 110 is formed on the outer side surface 112 of the barrel 110 . On the outer side surface 112 of the barrel body 110 , three chord sections 118 are formed at equal intervals to separate the outer threads 116 .

[0013] The chord cut surface 118 is formed by cutting the cylinder body 110 along the axis parallel to the cylinder body 110 with three equally spaced and equal length chords in the circumference formed by the outer side surface 112 as the starting point. The three chord sections 118 divide the external thread 116 on the barrel 110 into three symmetrically discontinuous main thread areas 116a. Preferably, the central angle of the main t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com