Ball-valve operated fuel injector

A fuel injector and injector body technology, which can be used in fuel injection devices, charging systems, machines/engines, etc., can solve the problem of high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

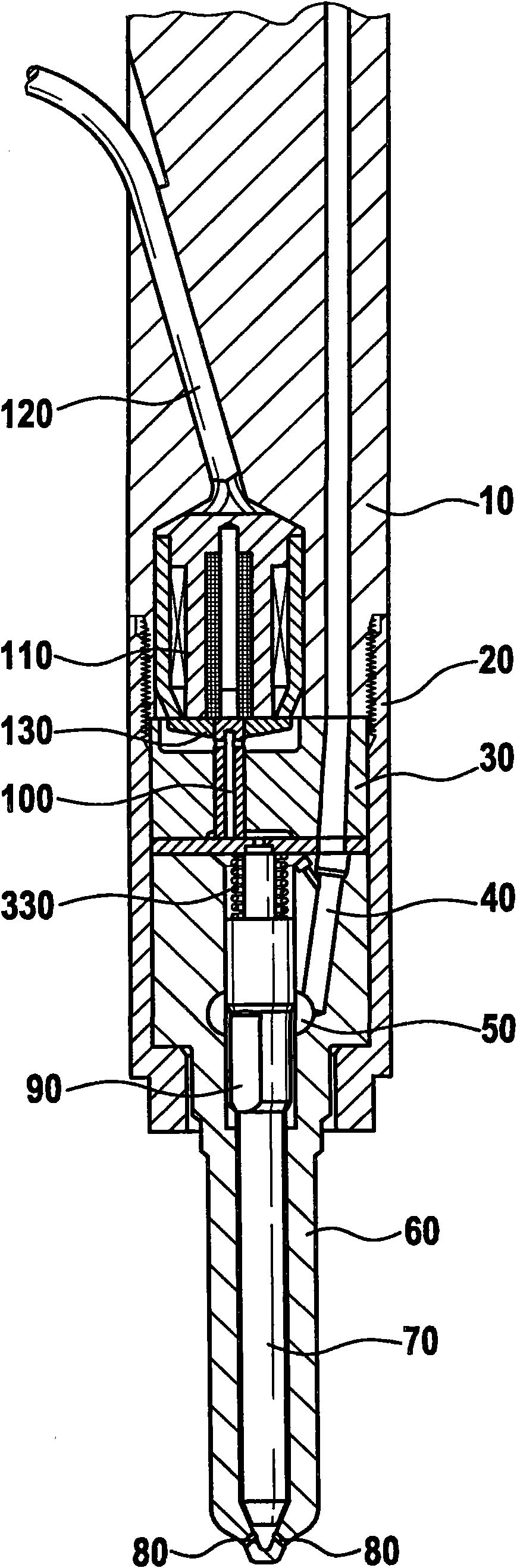

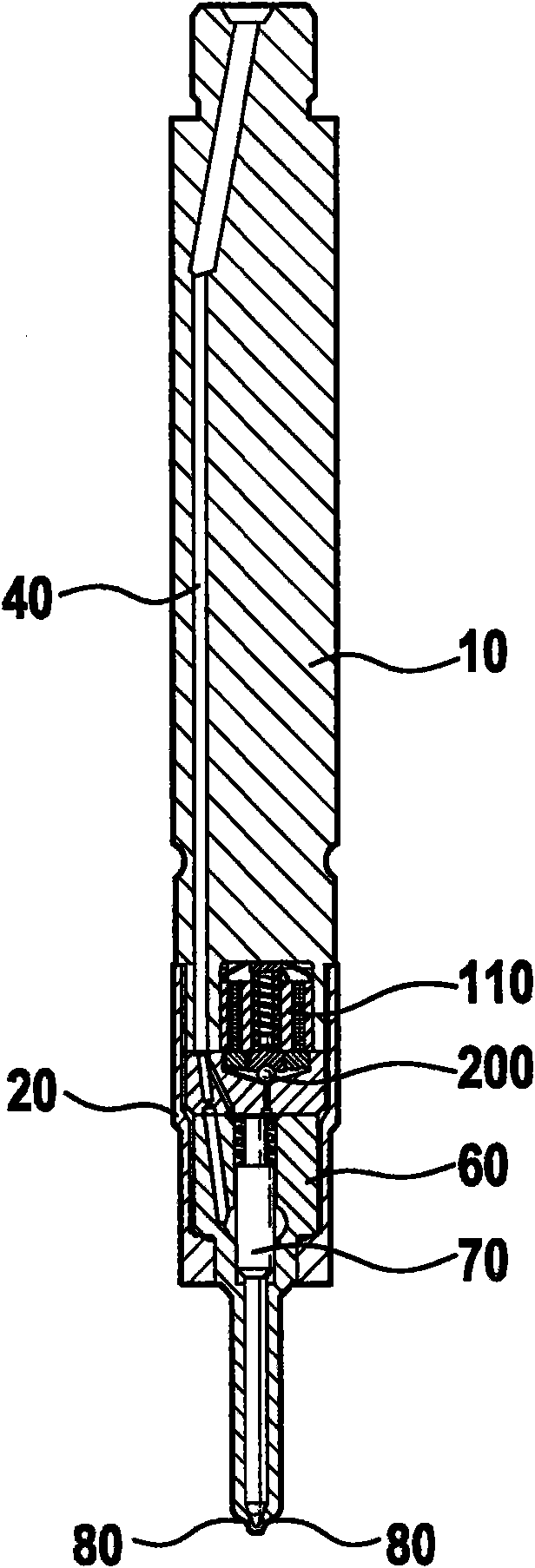

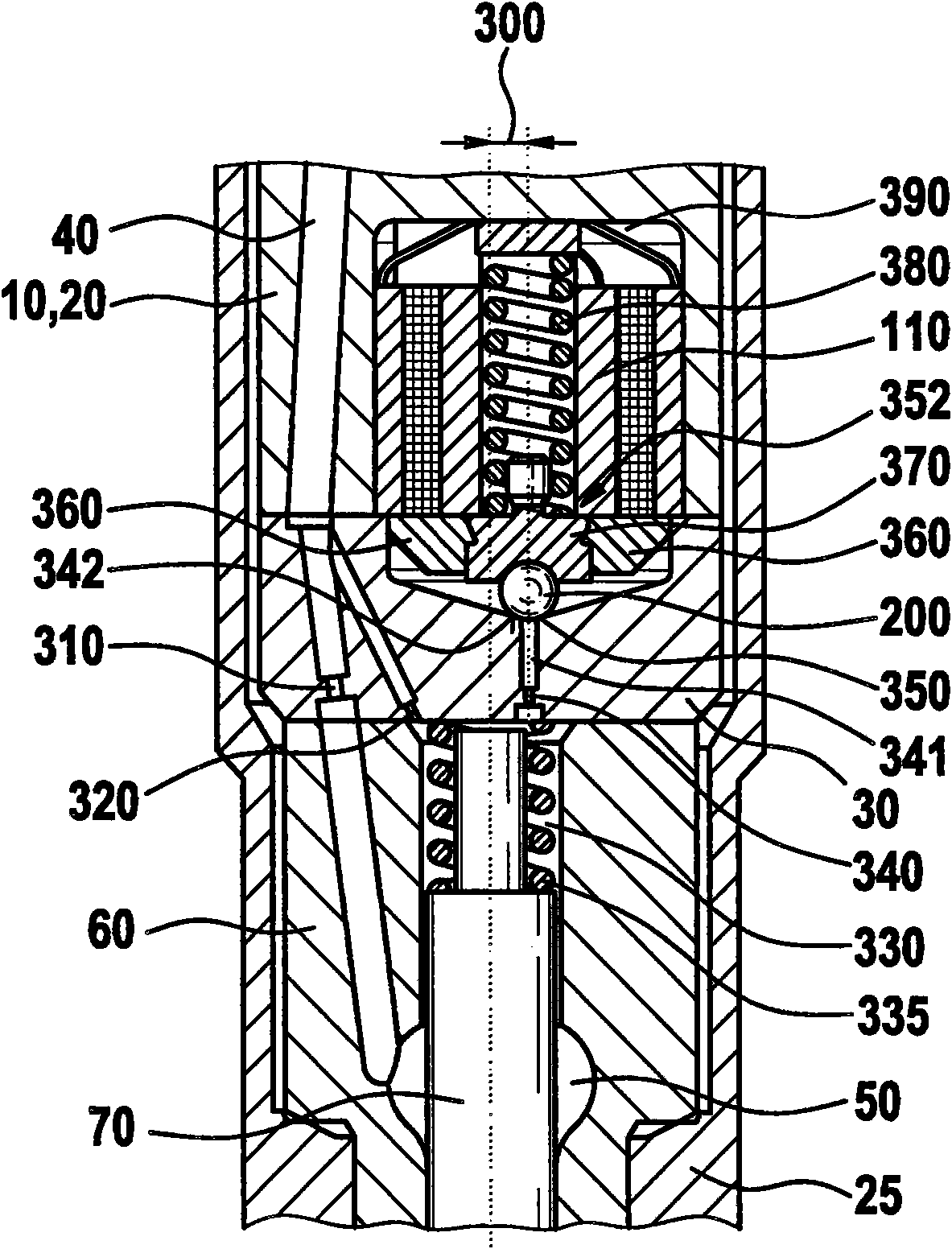

[0022] figure 1 A fuel injector according to the prior art is shown in , which is provided with a conventional valve needle.

[0023] The nozzle holder 10 includes a high pressure line 40 filled with fuel, such as diesel fuel. The nozzle holder 10 also includes an electromagnet 110 which is controlled via an electrical connection 120 . Electromagnet 110 is connected to a valve seat 130 and to an injection valve part 100 . If current is passed through electromagnet 110 , injection valve member 100 is moved along the first axis and the connection to control chamber 330 is released. In this way, the fuel located in the control chamber 330 flows out via the valve 100 and a suitable connection. The pressure in the control chamber 330 drops as a result of the outflow of fuel from the control chamber 330 .

[0024] Located in the lower part of the fuel injector is a nozzle body 60 , which includes an injection valve element 70 , which is preferably designed as a needle, and into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com