Food processor

A food processing machine and head technology, applied in beverage preparation devices, household utensils, applications, etc., can solve problems such as cleaning troubles and affecting the processing quality of processed materials, and achieve the effects of easy cleaning, less foam, and enlarged heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

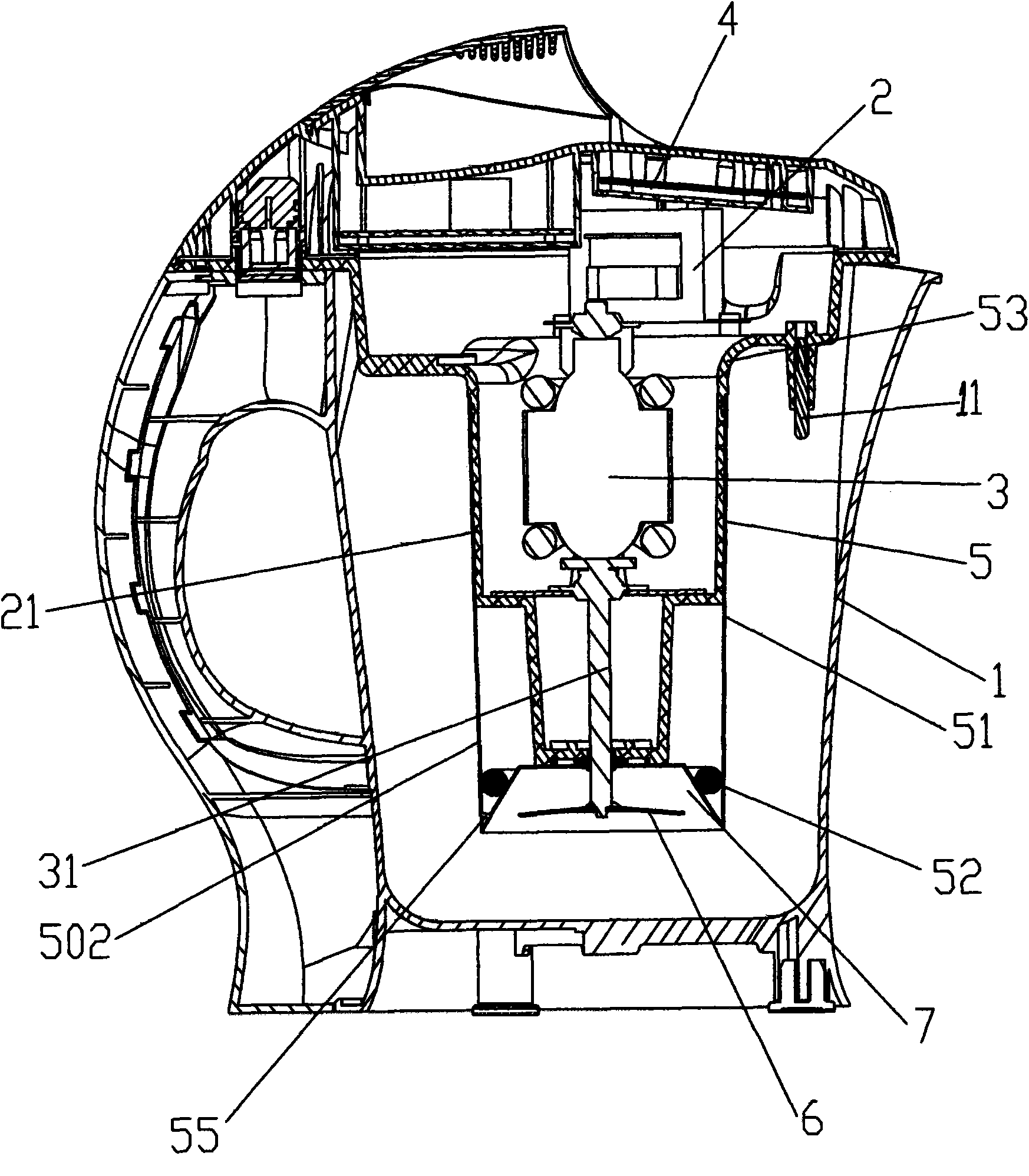

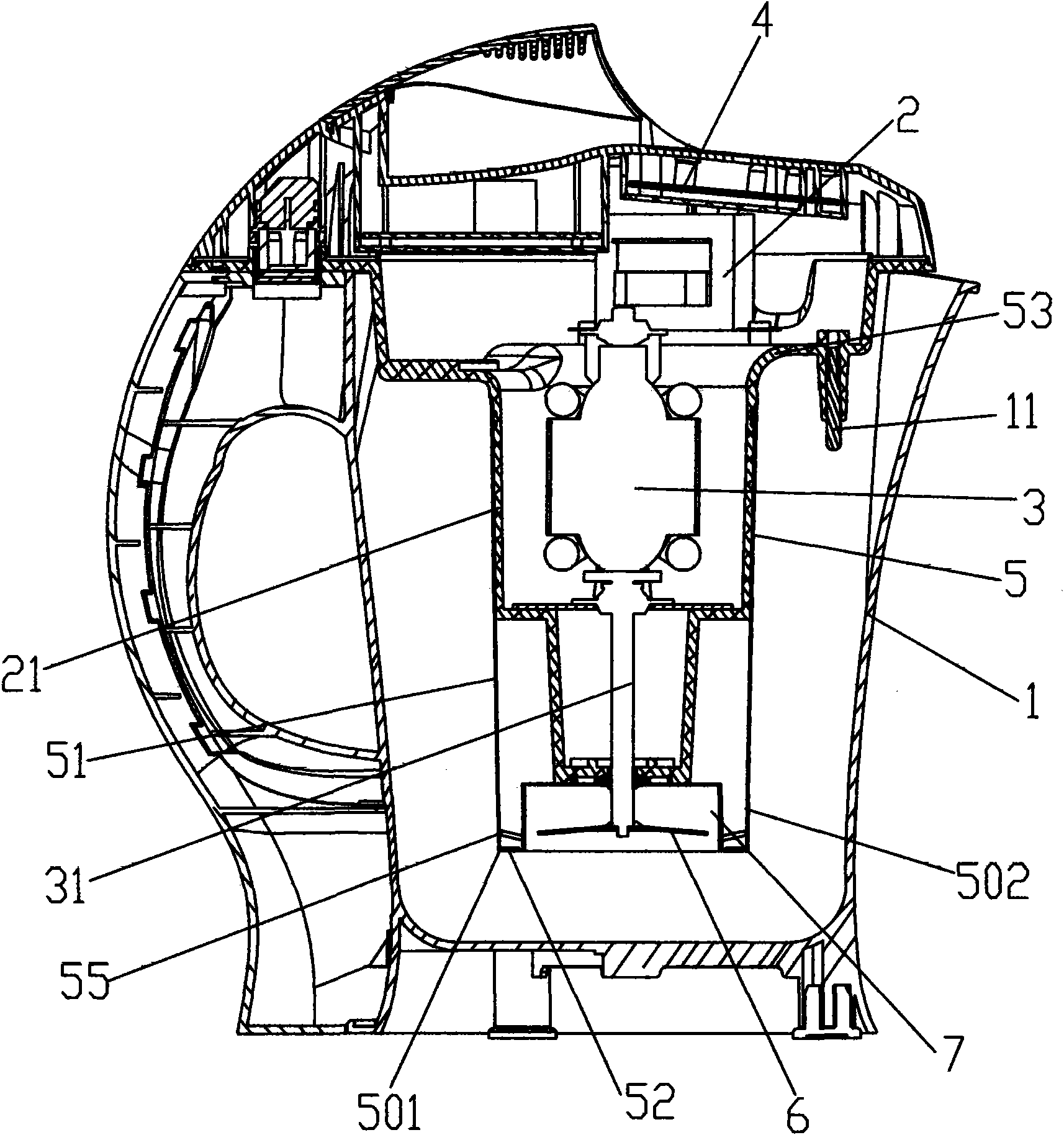

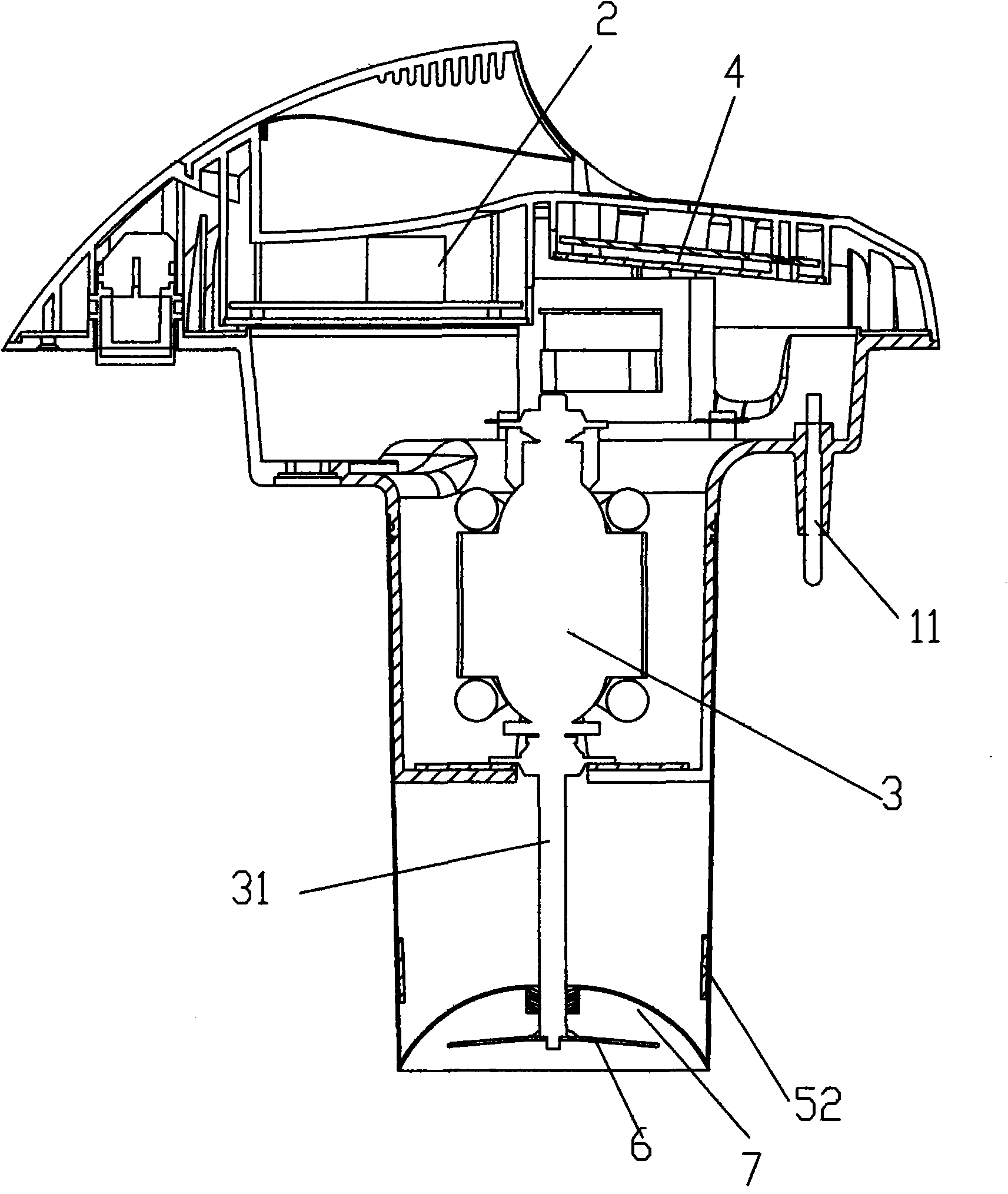

[0029] A kind of food processing machine, it comprises cup body 1 and machine head 2 that is sleeved on the cup body 1, motor 3, control circuit board 4 are housed in described machine head 2, the end of motor transmission shaft 31 of motor 3 is provided with There is a crushing blade 6; the lower end of the machine head 2 is provided with a sanitary protection cover 5 that wraps the motor 3 and the motor drive shaft 31 therein, and the bottom of the sanitary protection cover 5 is provided with a heating part 51 made of a metal material, A heating device 52 connected to the heating part 51 is provided inside the sanitary protective cover 5 . The heating part 50 is made of metal materials that meet food hygiene standards, such as stainless steel, aluminum, alloys and other materials. The heating jacket 5 can be a hollow body or a solid body. When processing materials, even if the heated materials stick to the heating jacket 5, it is very hygienic, and it is very convenient to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com