Method and device for single plate dislocation of metal plate laminates

A metal sheet, sheet metal technology, applied in transportation and packaging, object separation, thin material handling, etc., can solve the problems of unreliable handling, not compact enough, long travel of parts, etc., to achieve flexible selection of transmission mechanism, prevent diameter To the effect of poor rigidity and simple and compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

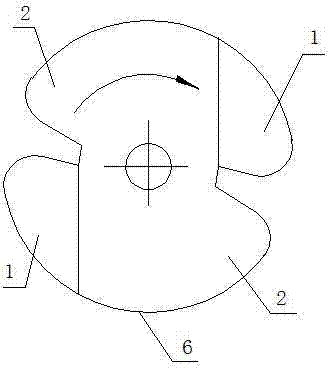

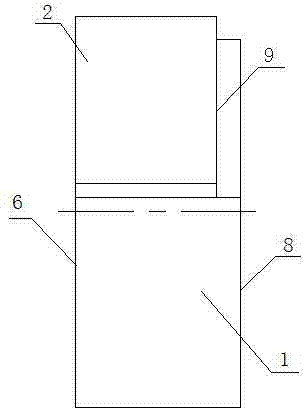

[0039] Adopt two dials 6 to displace the bottom sheet 4 of sheet stack 3, its working process is as follows: image 3 , Figure 4 , Figure 5 and Image 6 As shown, the height of the part used to move the single piece of sheet material 4 is smaller than the thickness of the sheet when the sideways toggle pendulum block 1 starts to pick the tabs, and the sideways toggle pendulum block 1 works with the stopper 5, which can effectively prevent Misplaced excess sheet.

[0040] First, the flange portion 7 of the sheet stack 3 is placed on the contact surface 9 (see image 3 and Figure 4 ),according to image 3 Rotate the turntable 6 in the direction, and move the pendulum block 1 sideways to move the flange part 7 of the bottom single sheet material 4 to rotate and displace, so that the flange part 7 of the bottom single sheet material 4 gradually rotates away from the axial limit pendulum block 2 (see Figure 5 ), the contact surface 8 gradually enters under the flange par...

specific Embodiment 2

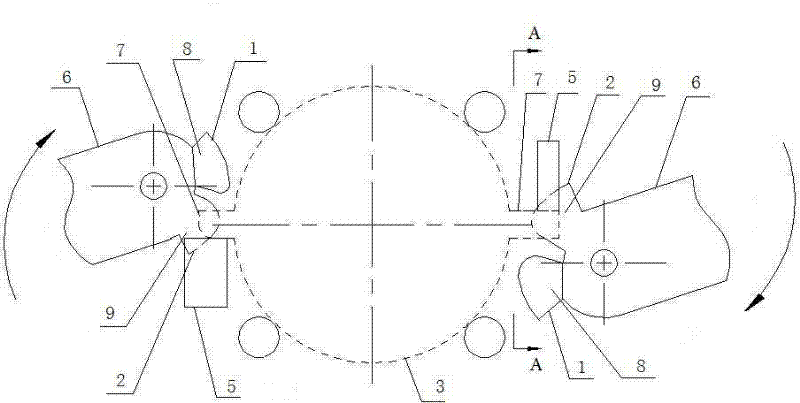

[0043] Reference as Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, two pairs of lateral toggle pendulum block 1 and axial limit pendulum block 2 are used to rotate according to the direction shown in the figure, and the lateral toggle pendulum block 1 is used to toggle the uppermost outer single sheet of sheet material stack 3 4 Make it rotate misaligned with the rest of the sheet material stacks 3 . Its working process is as follows.

[0044] The outer peripheral portion of the sheet material is polygonal, and the junction of two adjacent outer edges has a protruding portion connected to the contact surface 9. When the turntable 6 is rotated, the contact surface 9 of the axial limit pendulum block 2 is separated from the single sheet material 4. , the contact surface 8 of the pendulum block 1 is pressed against the protruding part of the rest of the sheet metal stacks 3 (see Figure 9 and Figure 10 ), the stopper 5 descends together with the dial 6.

[004...

specific Embodiment 3

[0047] refer to Figure 11 , Figure 12 and Figure 13 As shown, use two pairs of lateral toggle pendulum 1 and axial limit pendulum 2 to rotate in the direction shown in the figure, and lateral toggle pendulum 1 to toggle the outermost sheet 4 of the slanted sheet stack Make it and sheet material stack 3 translation dislocation. Its working process is as follows.

[0048] The outer peripheral portion of the sheet material is polygonal, and the junction of two adjacent outer edges has a protruding portion connected to the contact surface 9. When the turntable 6 is rotated, the contact surface 9 of the axial limit pendulum block 2 is separated from the single sheet material 4. , when the contact surface 8 of the pendulum block 1 is moved laterally against the protrusions of the rest of the sheet stacks 3; when the turntable 6 is continued to be rotated, the contact surface 8 of the pendulum block 1 is separated from the rest of the sheet stacks 3 , the contact surface 9 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com