Non-rope circulating multi-cabin elevator and circulating system thereof

A circulatory system, multi-car technology, applied to elevators, lifts, transportation and packaging in buildings, etc., can solve the problems of small number of cars in high-rise buildings, low space utilization efficiency, complex car moving mechanism, etc. Solve the effect of long waiting time and improve space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

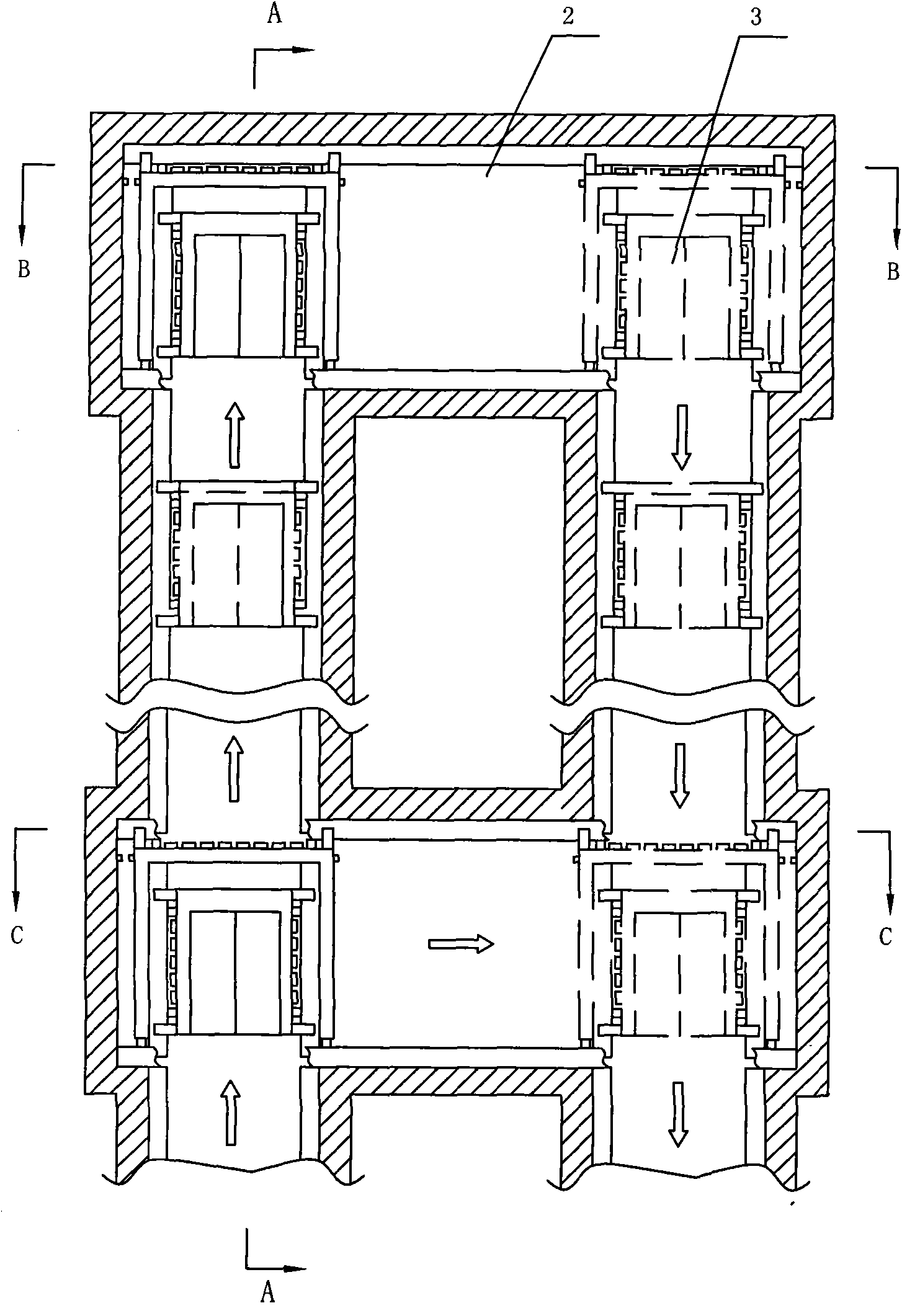

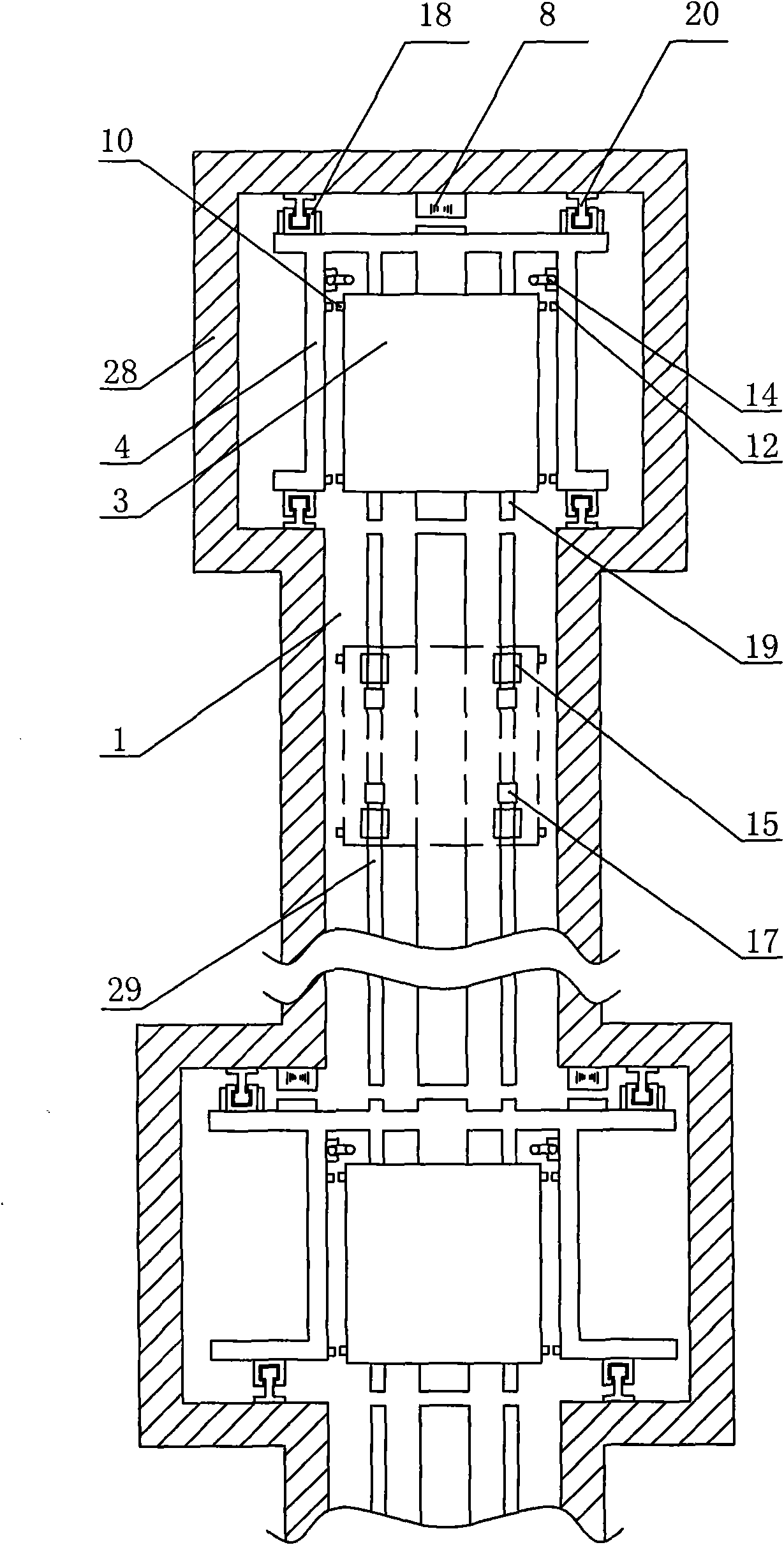

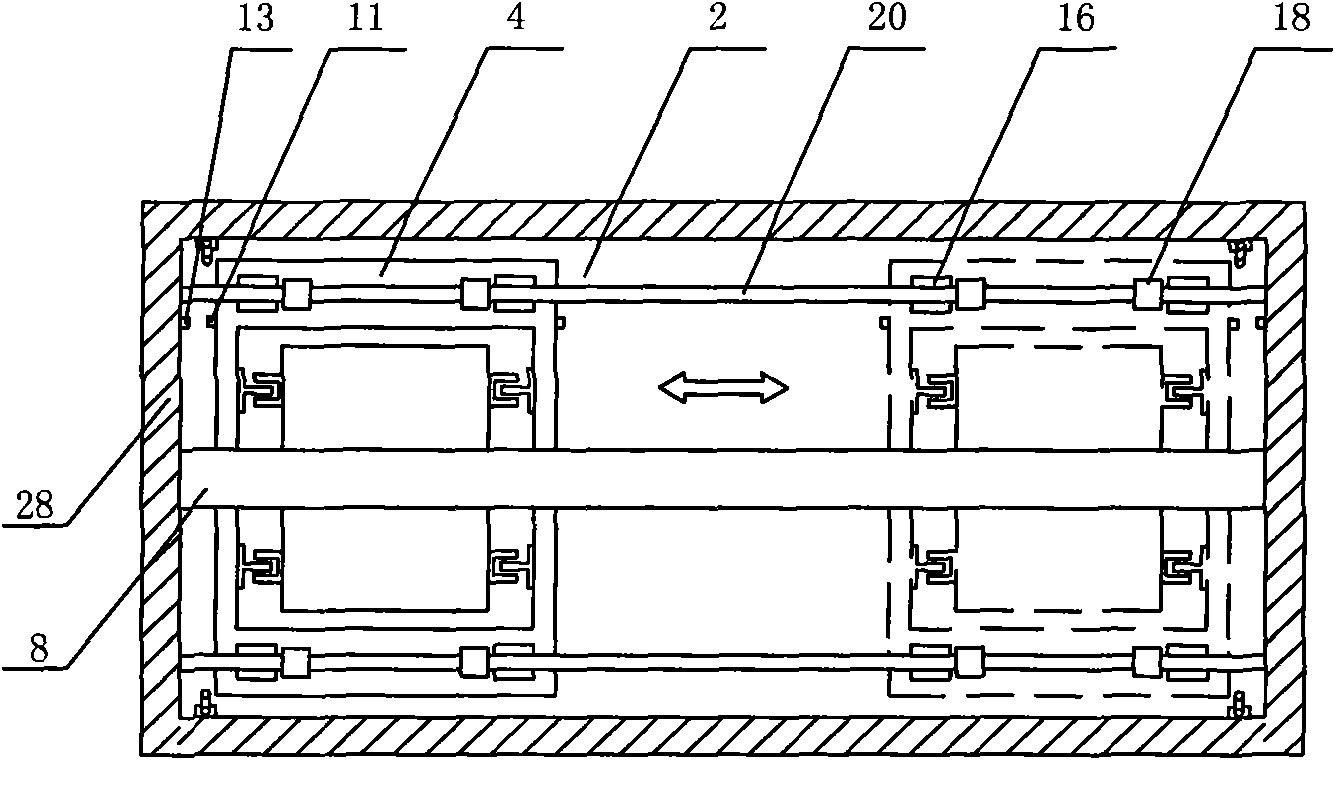

[0037] Such as figure 1 , 2 , Shown in 3 and 4, a kind of cordless circulation multi-car elevator, comprises vertical shaft 1 and car 3, fixed lifting guide rail II 29, lifting power mechanism and control system in the vertical shaft. The lifting power mechanism is a permanent magnet linear motor 6 arranged between the car 3 and the shaft wall 28 . A horizontal shaft 2 is set on the vertical shaft; a mobile frame 4 is installed in the horizontal shaft 2, and the lifting guide rail Ⅰ19 is fixed on the mobile frame 4, and the lifting guide rail Ⅰ19 and the lifting rail Ⅱ29 are jointed with a slot; the corresponding permanent magnet in the vertical shaft The linear motor 6 and the permanent magnet linear motor 6 in the moving frame are jointed with a seam; a moving frame transfer mechanism is arranged in the horizontal shaft. The moving frame transfer mechanism is a fixed translation guide rail I20 inside the horizontal shaft, and a translation guide shoe 18 is arranged outside...

Embodiment 2

[0040] Such as Figure 5 , 6 As shown, the moving frame transfer mechanism is a rotating arm arranged in the horizontal shaft. The rotating arm includes a rotating motor 25 fixed on the horizontal shaft, a gear 31 is fixed on the output shaft of the rotating motor 25, and the gear 31 meshes with the ring gear 32 fixed on the rotating shaft 26. In the upper bearing 33, the connecting frame 27 is fixed on the rotating shaft 26, and one end of the connecting frame 27 is fixed on the mobile frame 4 one side, and other structures are the same as embodiment 1.

[0041] After the car and the mobile frame are fixed together, the rotary motor 25 starts to work, and the gear 31 on the output shaft of the rotary motor 25 drives the rotating shaft 26 to rotate through the ring gear 32, and the rotating shaft 26 drives the mobile frame and the car to rotate, so that the car can be rotated in different positions. The transfer in the vertical well shaft, other modes of operation are the sa...

Embodiment 3

[0043] Such as Figure 7 , 8 , 9, the moving frame transfer mechanism is an annular turret arranged in the horizontal shaft. The horizontal shaft of the annular turret is fixed with a translation guide rail II30, and a translation guide shoe 18-1 is arranged outside the translation guide rail II30. The translation guide shoe 18-1 is fixed on the mobile frame 4, and the translation brake 16-1 is fixed on the mobile frame 4; Arc linear motor 8-1 is arranged between frame 4 and horizontal shaft 2, and its structure is the same as embodiment 1.

[0044]After the car and the moving frame are fixed together, the arc-shaped linear motor 8-1 starts to be energized to drive the moving frame to slide along the translation guide rail II 30, and other operating modes are the same as in embodiment 1. When the car is transferred from one vertical shaft to another vertical shaft, another mobile frame moves to the original vertical shaft to prepare for the next transfer of the car. With su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com