Oblique rolling shaft angle turning machine of emulsion explosive production line

An emulsion explosive, production line technology, applied in explosives, explosive processing equipment, offensive equipment and other directions, can solve the problems of high failure rate of carton diverter, low work efficiency, affecting the stable production performance of packaging line, etc., to achieve automatic production process, The effect of high work efficiency and stable production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

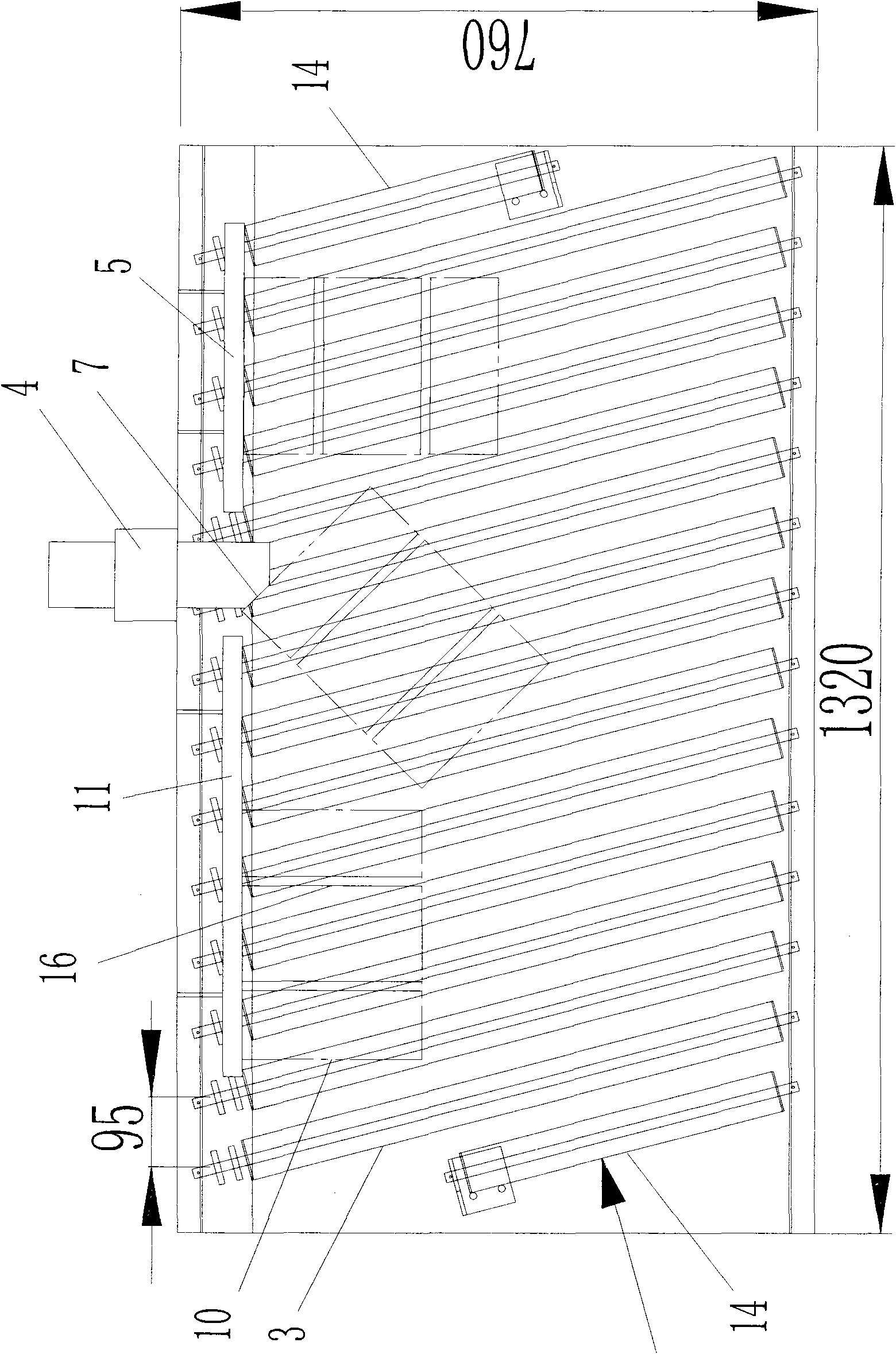

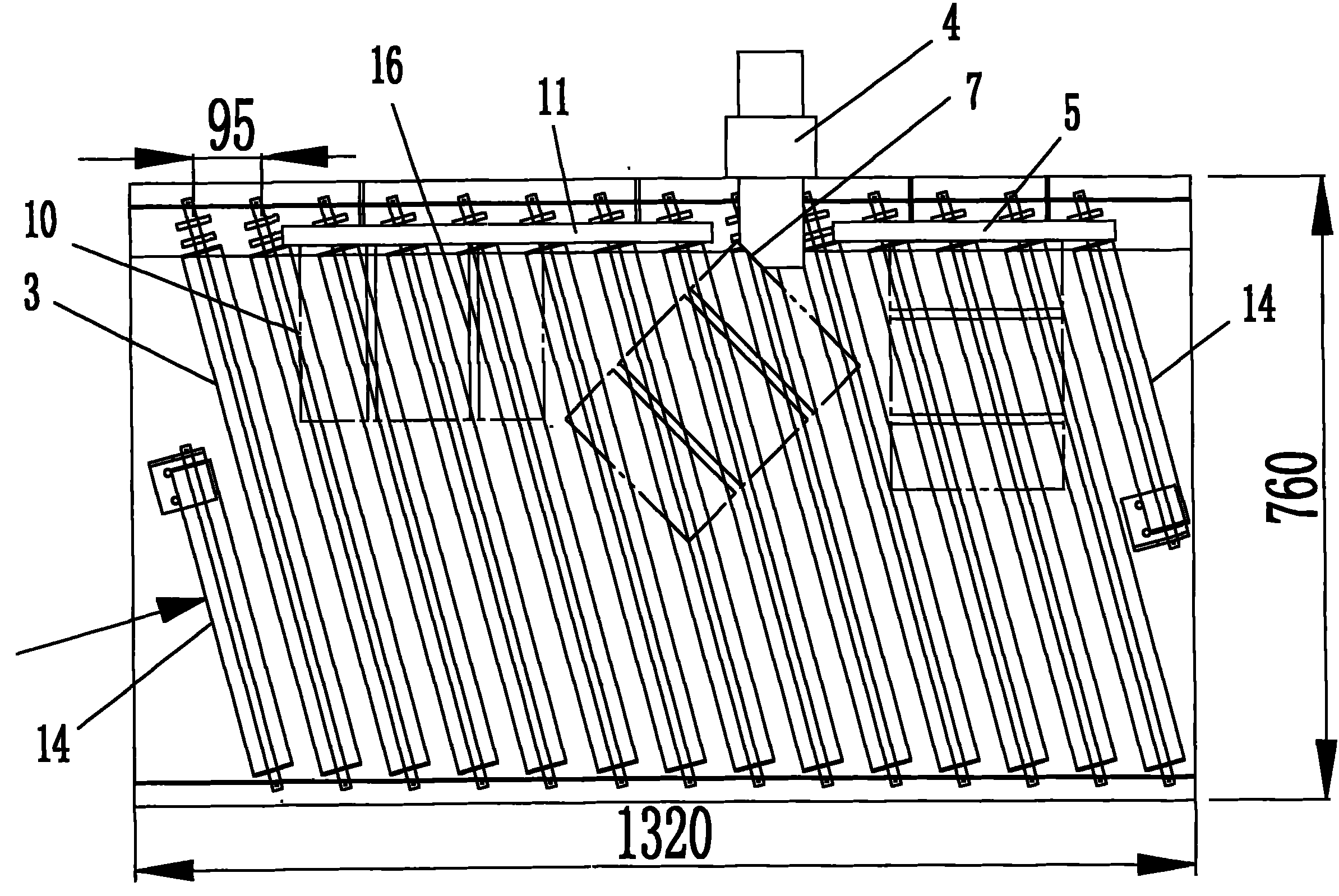

[0022] Such as figure 1 and figure 2 The inclined roller corner machine of the emulsion explosive production line shown includes a bracket 1, a geared motor 2, a power drum 3, a corner block 4, and a guide bar 5. The geared motor 2 is connected to drive the power drum 3, and multiple power drums 3 are arranged in parallel and evenly. Set on the beams 6 on both sides of the bracket 1, the angle between the power drum 3 and the beam 6 is 60°, the corner block 4 is set on one side of the bracket 1, and the corner block 4 is provided with a 45° chamfer 7, chamfer 7 Facing the direction of rotation of the power drum 3 , the guide bar 5 is arranged on the side of the bracket 1 where the corner block 4 is located, and the guide bar 5 is located behind the corner block 4 .

[0023] The reduction motor 2 is connected to drive the power drum 3 through a chain 8, and two adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com