Driving device of whitewashing machine

A technology of driving device and painting machine, which is applied in the direction of construction and building construction, can solve the problems of high cost, difficult mechanical construction, complicated mechanical structure, etc., and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

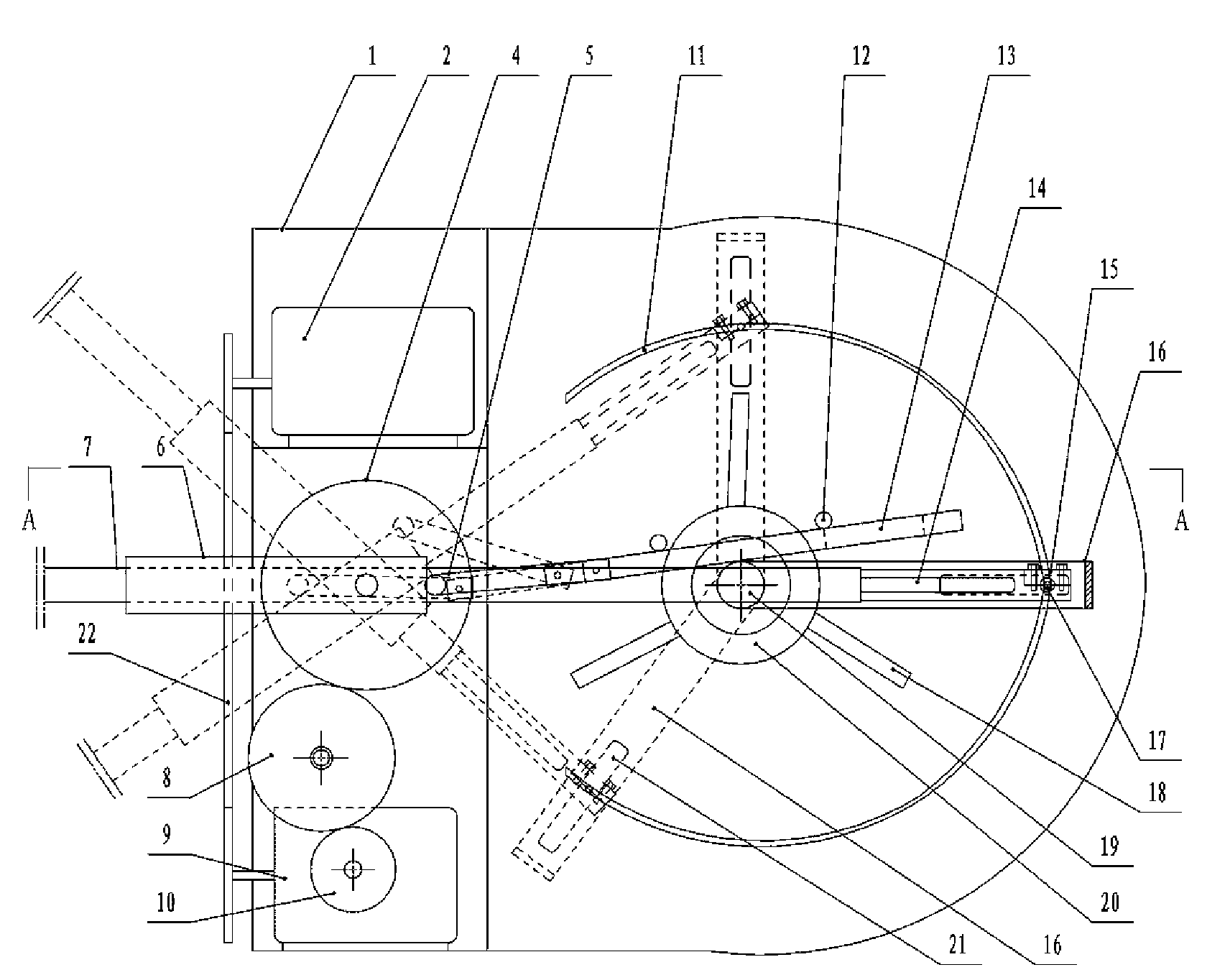

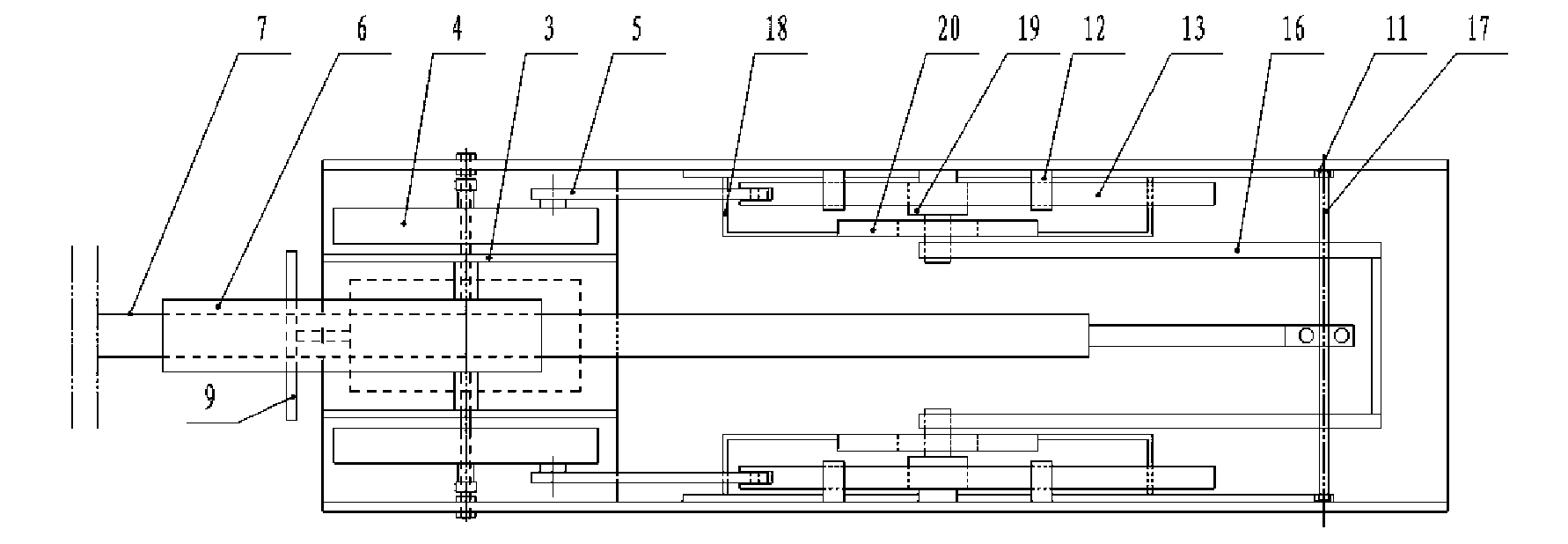

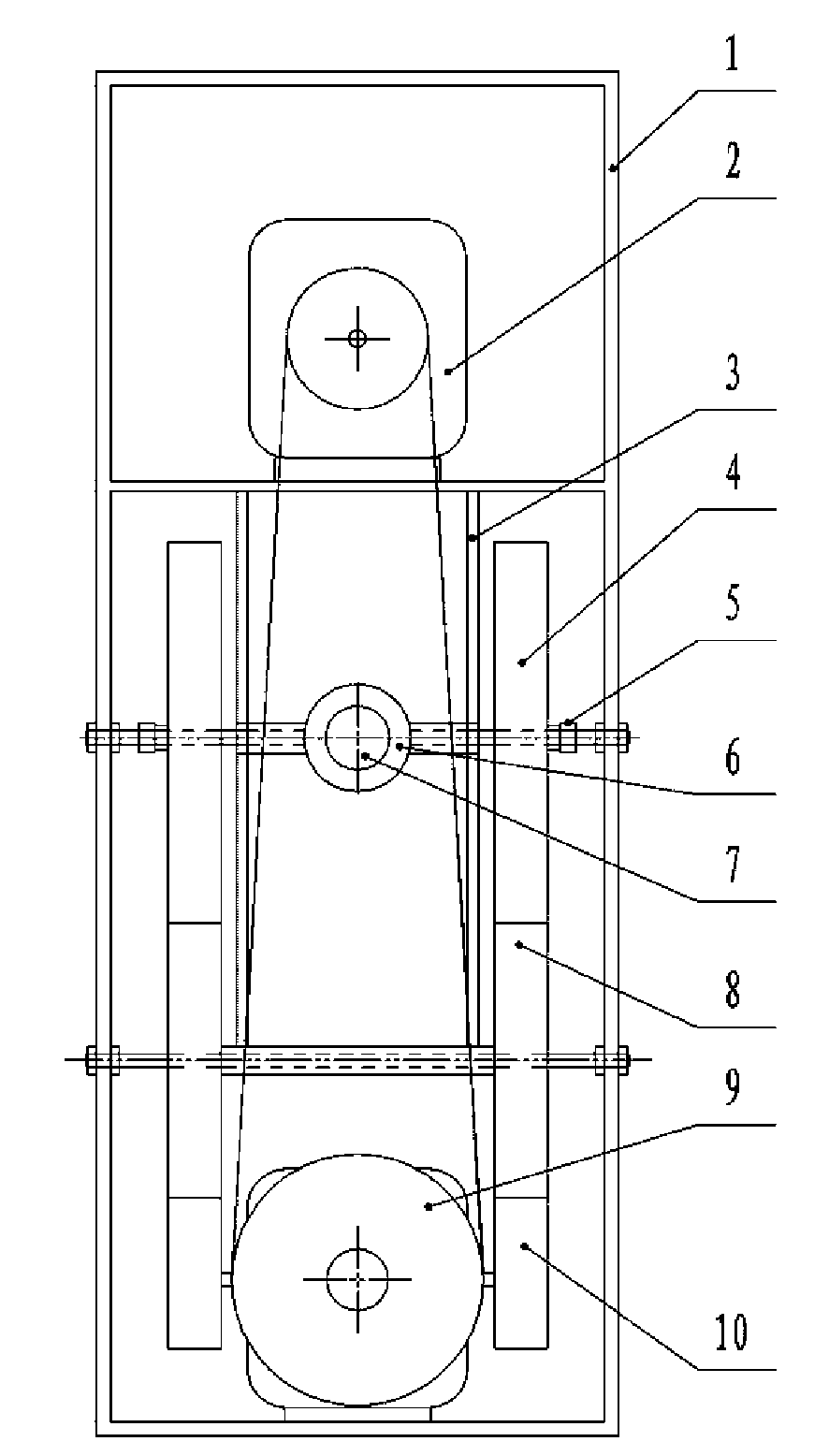

[0020] Embodiment 1, the present invention is a driving mechanism composed of components such as a reducer gear 10, a large gear 4, an eccentric rocker 5, a rack 13, a gear 19, a driving rocker 16, and a driving connecting rod 17 in the housing 1. , for driving the outer end of the slide bar 7 to move along a straight line, that is, to ensure that the outer end of the slide bar 7 can move up and down and telescopically.

[0021] The rocker mounting base 20 is fixedly installed on the inner wall of the housing 1 through the rocker mounting bracket 18, the driving rocker 16 and the gear 19 are fixedly installed on the same rotating shaft, and one end of the rotating shaft of the driving rocker 16 and the gear 19 is installed on the housing 1 In the inner wall support of the inner wall support, the other end is installed in the rocking bar mounting seat 20; also can be respectively sleeved with the bearing that cooperates with the rotating shaft in the inner wall support and the r...

Embodiment 2

[0026] Embodiment 2, the present invention also can be provided with support 3 in housing 1, is respectively installed with reducer gear 10, bull gear 4, eccentric rocker 5, tooth rack 13, gear 19, drive on both sides of support 3. The drive mechanism that rocking bar 16 forms, the outer end of the drive rocking bar 16 of both sides adopts connecting rod to be fixedly connected, so that the drive mechanism on both sides can work synchronously. The slide bar sleeve 6 is installed between these two sets of driving mechanisms, and arc guide grooves 11 can be respectively arranged on the inner walls of both sides of the housing 1, and the two ends of the drive connecting rod 17 are respectively sleeved on the arc guide grooves on both sides. In the slot 11, the movement balance of the slide bar 7 can be better ensured. refer to Figure 1 to Figure 6 , all the other are with embodiment 1.

Embodiment 3

[0027] Embodiment 3, in the present invention, the inner end of the slide bar 7 can also be made into a ladder-shaped notch, and a semicircular through groove that matches the drive connecting rod 17 is set on the ladder-like notch, and at the same time, the end of the slide bar is also installed The block 15 is provided with a semi-circular through groove matching with the drive link 17, and the mounting block 15 at the end of the slide bar is installed on the upper part of the ladder-shaped notch, and the mounting block 15 at the end of the slide bar can be fixed by bolts, screws or screw sleeves Installed on the ladder notch. It is also possible to set a semicircular through groove matching with the drive connecting rod 17 at the inner end of the slide bar 7, and at the same time, also be provided with a semicircular through groove matching with the driving connecting rod 17 on the mounting block 15 at the end of the slide bar , The mounting block 15 at the end of the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com