Method an apparatus to control the starting procedure of an internal combustion engine

A technology of internal combustion engine and starting process, applied in the direction of internal combustion piston engine, combustion engine, engine control, etc., can solve the problem of increasing fuel, achieve the effect of improving vaporization, reducing emissions, and increasing vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

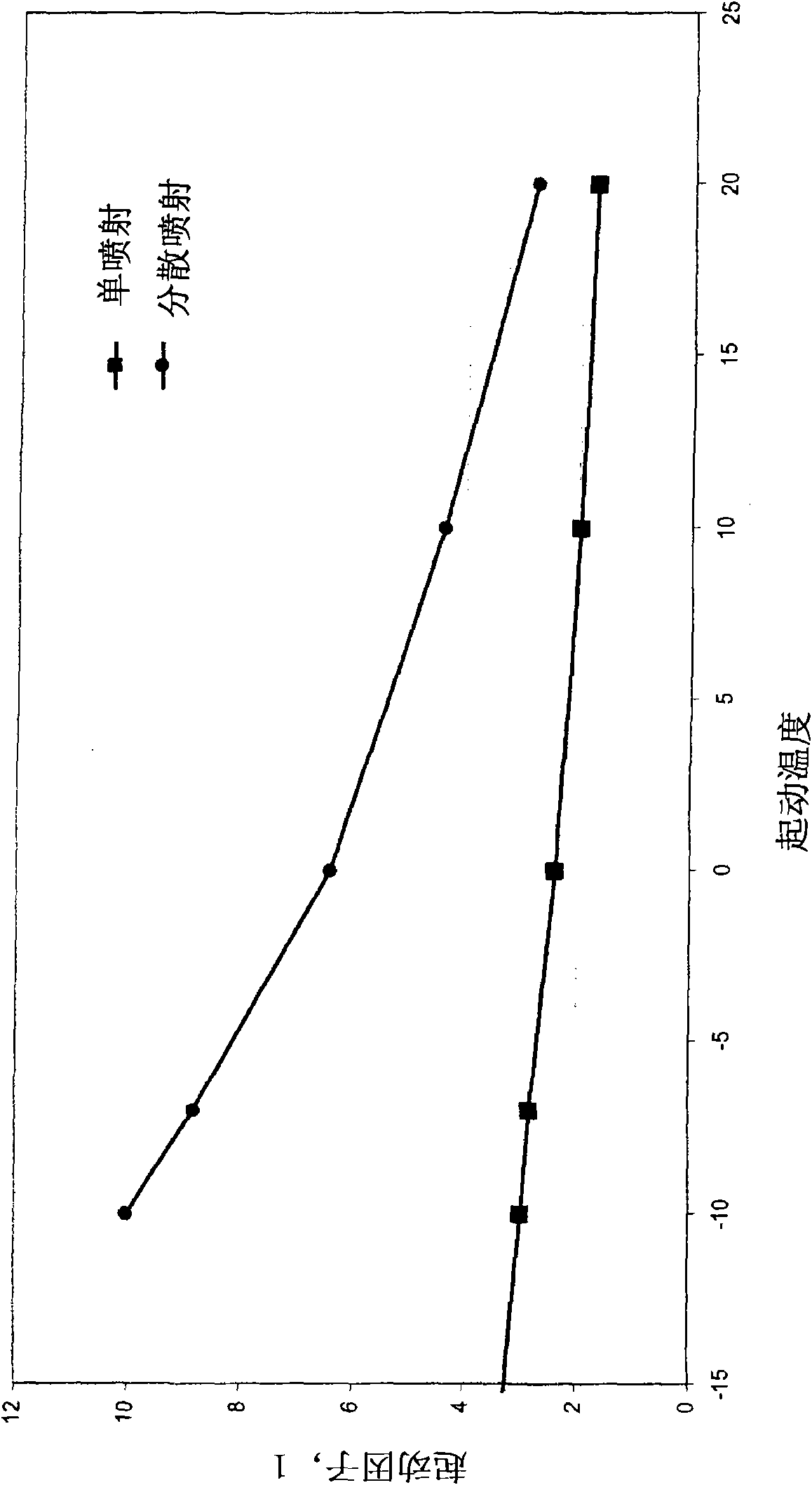

[0019] first reference image 3 Explain the problems mentioned in the introduction with the known "spread" injection mode when starting an internal combustion engine and at low temperatures. image 3 The curve for shows the so-called cranking factor, the excess growth of fuel injection required to achieve a sufficient amount of fuel vapor compared to the amount of fuel actually required for combustion purposes, plotted as a function of cranking temperature.

[0020] image 3 The upper curve of , shows the start factor for a typical split start regime, where the start of the first injection (SOI 1) occurs at a crank angle (CA) of 250° before top dead center (BTDC), and the end of the second injection (EOI 2) occurs at a crank angle of 60° before top dead center, the dispersion ratio (ratio of the first injection to the second injection) is from 40% to 60%, the ignition advance is 5°, and the E85 is used fuel.

[0021] With this type of dispersion, the following adjustment da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com