Percussive drill bit for rock drilling and method for the manufacture of such drill bit

A technology of percussion drill bit and rock drill is applied in the field of impact drill bit used for rock drilling and used for manufacturing the drill bit, which can solve the problems of complex, expensive and difficult to operate drilling equipment as a whole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

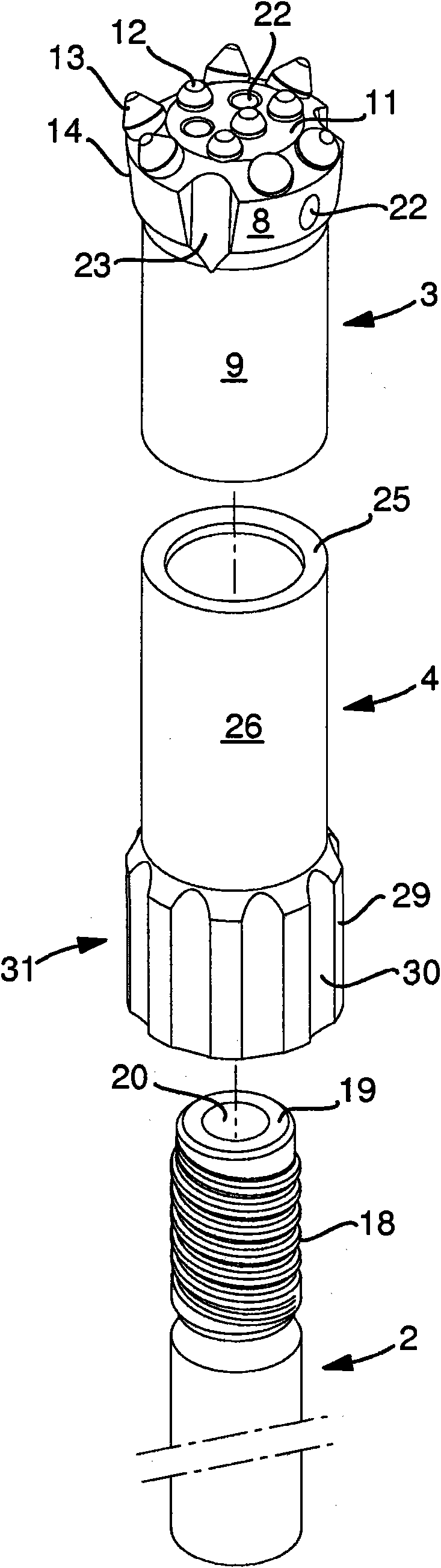

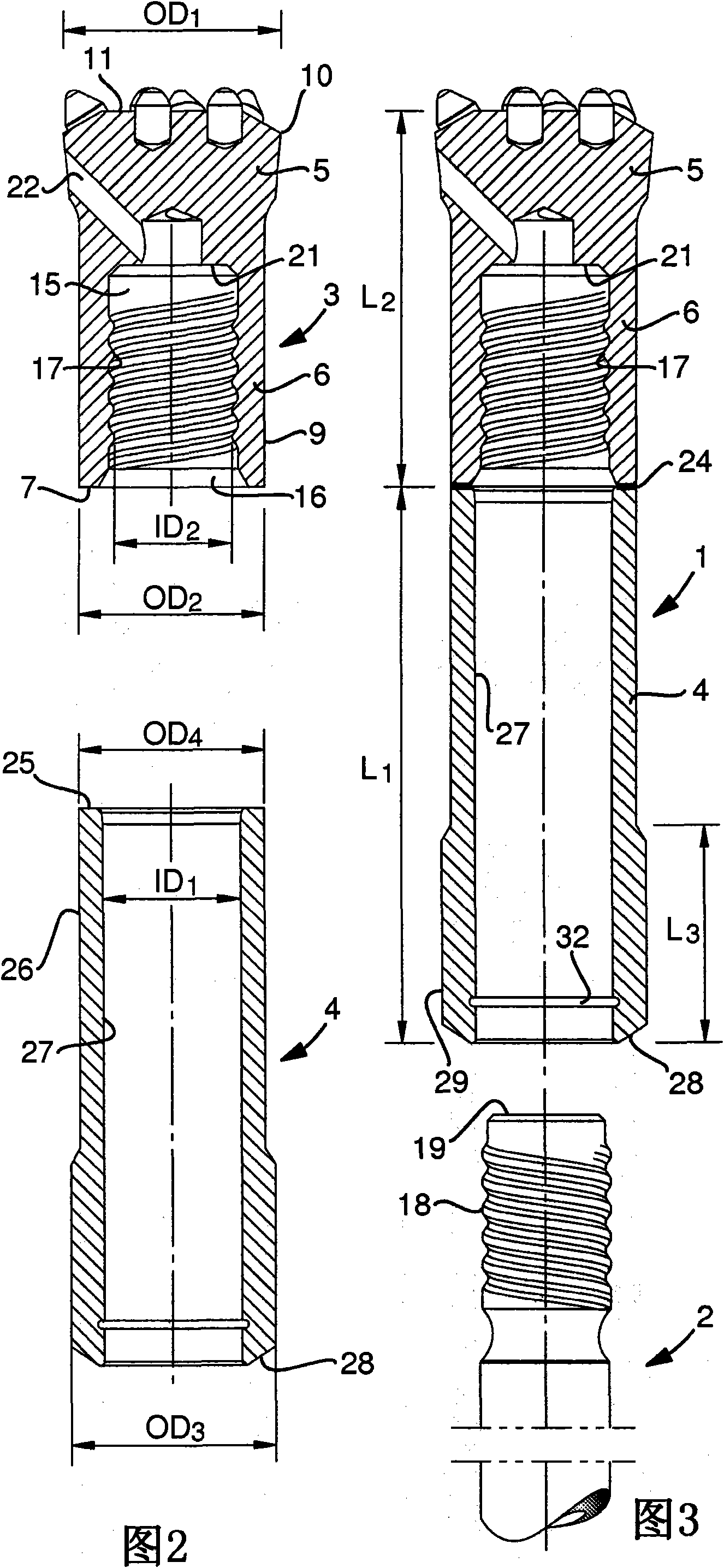

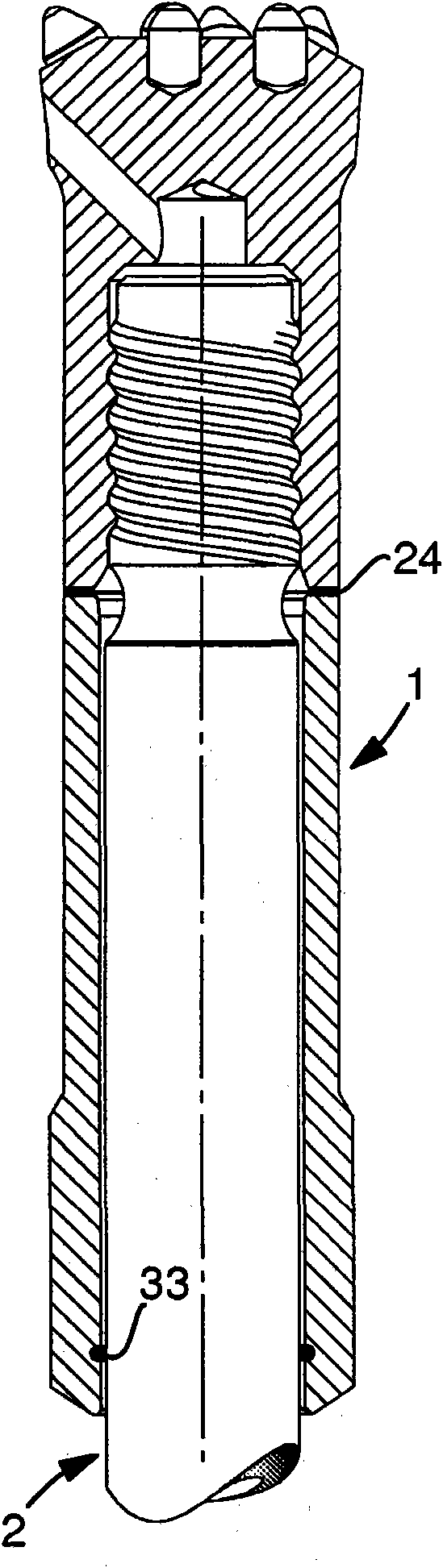

[0014] In the drawings, 1 roughly represents a drill bit manufactured according to the present invention (see image 3 with 4 ), the drill bit 1 is used to couple with the drill rod 2 included in the drill string. in figure 1 with figure 2 It can be seen that the drill bit 1 is manufactured by assembling two parts, the front part 3 and the rear part 4 together. In these two parts 3 and 4, the front part is made into a traditional drill. Thus, the portion 3 includes a front head 5 and a tubular skirt 6 extending from the head 5 to the annular rear end 7. The front part 3 has a rotationally symmetric basic shape by including a rotationally symmetrical envelope surface composed of a tapered surface 8 on the outside of the front head 5 and a cylindrical surface 9 on the outside of the skirt 6. The tapered surface 8 converges in the rearward direction from the circular dividing line 10, and the tapered surface transforms into the front surface 11 along the circular dividing line 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com