Method for removing sulfur dioxide in flue by using desulfurization liquor

A technology of sulfur dioxide and desulfurization liquid, which is applied in the field of desulfurization liquid in the flue to remove sulfur dioxide, can solve the problems of failing to meet the emission standards required by environmental protection, large additions, etc., achieve significant substantive effects, improve work efficiency, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

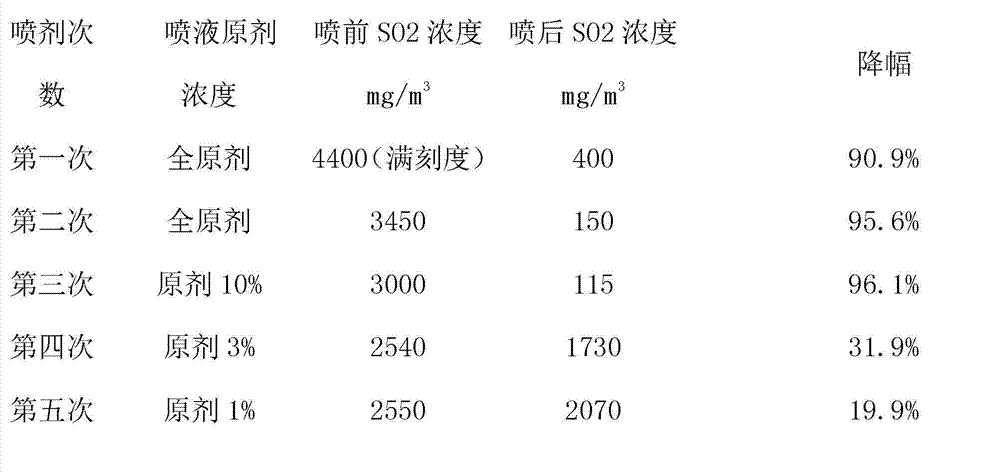

[0015] The technical solution of the present invention will be further described below through specific examples.

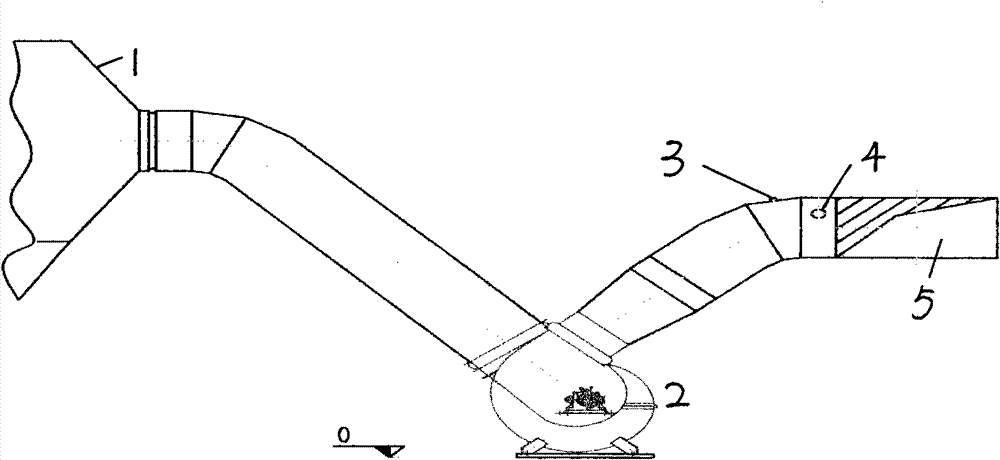

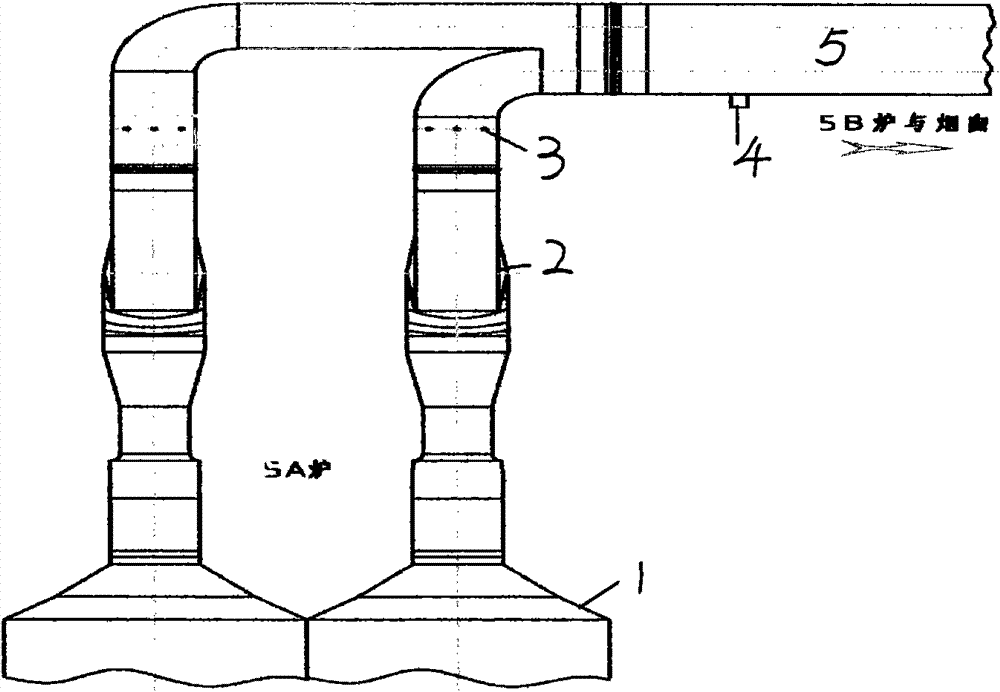

[0016] A method for removing sulfur dioxide with a desulfurization liquid agent in a flue. In the concrete horizontal flue 5 at the outlet of the boiler flue gas tail gas induced draft fan 2, the desulfurization liquid agent is sprayed in the direction of the air flow to carry out the sulfur dioxide removal reaction. After removing the sulfur dioxide The net flue gas is discharged into the atmosphere.

[0017] The composition and weight percentage of the desulfurization liquid agent in the present invention are: quaternary ammonium base organic matter 50%, 60%, 70% or 80%, organic solvent 20%, 30%, 40% or 50%, pH value 12-14. Wherein the organic solvent can be ethanol, methanol, ethylene glycol ether, isopropanol and ammonium isopropoxide.

[0018] The weight ratio of the desulfurization liquid agent of the present invention to sulfur dioxide in the flue gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com