Patents

Literature

32results about How to "Highlight the substantive effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for promoting light oil yield of atmospheric and vacuum distillation of petroleum oil

InactiveCN1884441AImprove light oil yieldNo need to change the structureHydrocarbon distillationAcetic acidOrganic solvent

The invention relates the method for improving atmospheric and vacuum distillation light oil productivity. The method comprises the following step: adding the 0.001-0.1wt% addition agent with colophony into crude oil in atmospheric and vacuum distillation tower. The addition agent comprises 50-80% colophony and 50-20% organic solvent. The pH is 7.0-7.5. The organic solvent comprises ethanol or cellosolve or ethyl propyl acetone or acetate cellosolve. The method can be used in oil-extraction plant, and the light oil productivity is improved by 1.5-2.3wt%.

Owner:SHANGHAI JIAO TONG UNIV

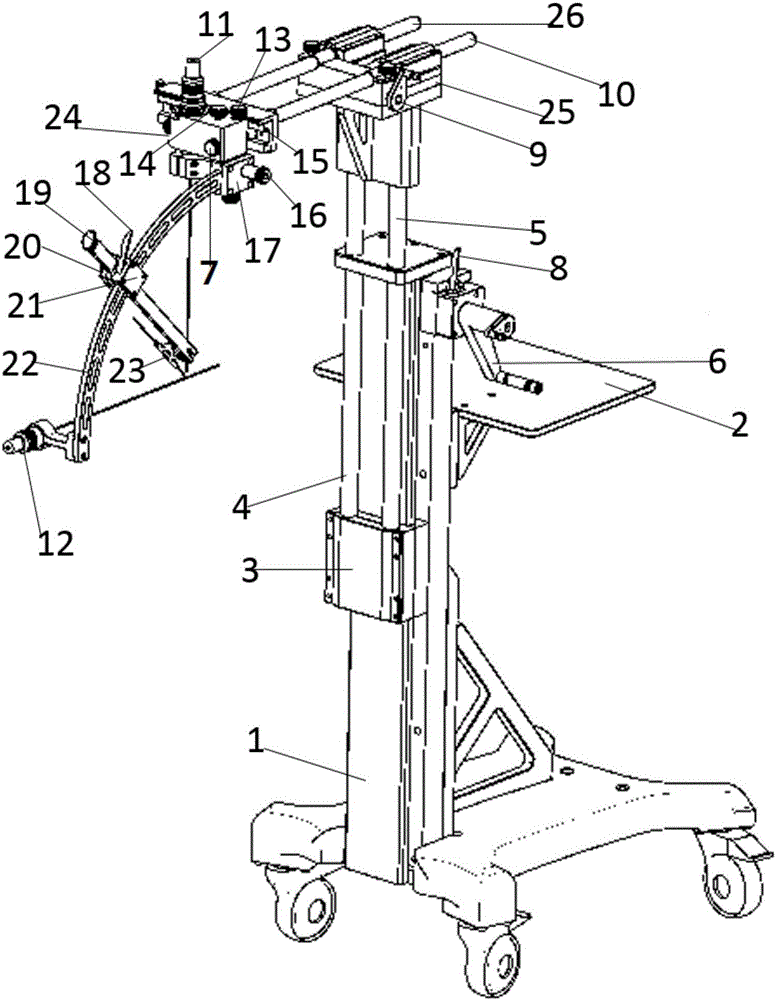

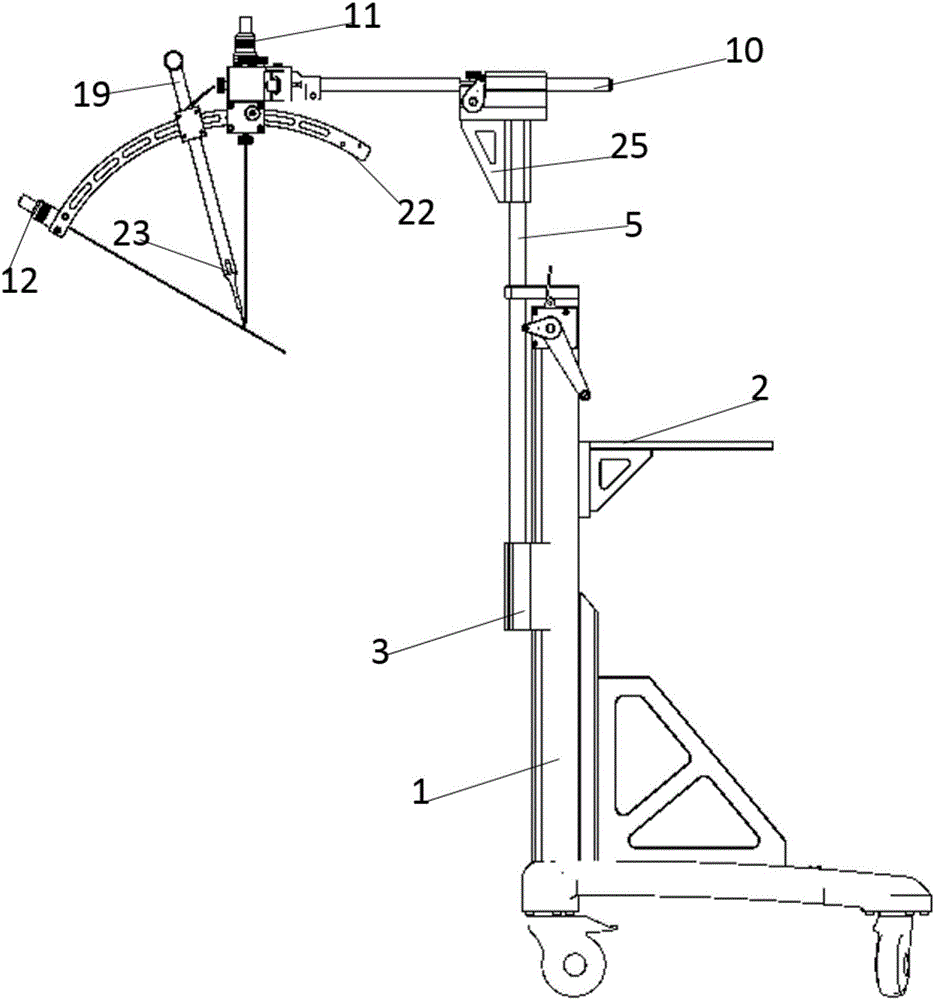

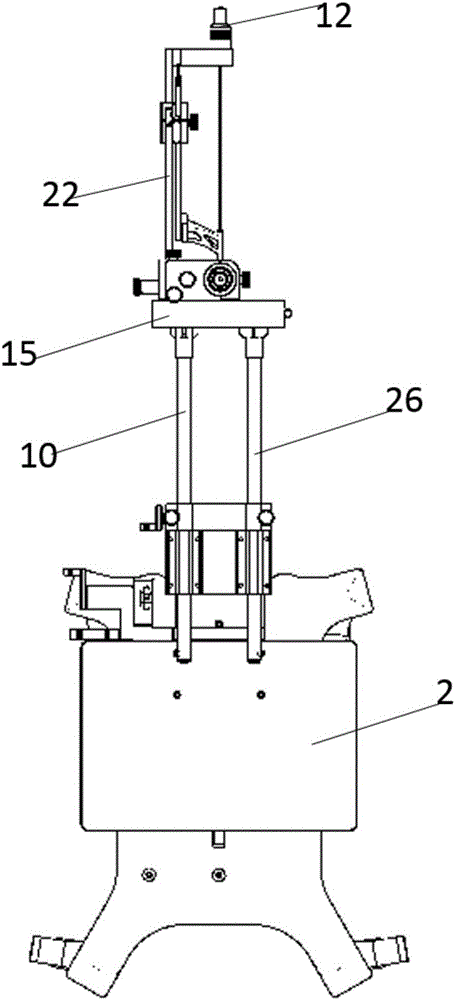

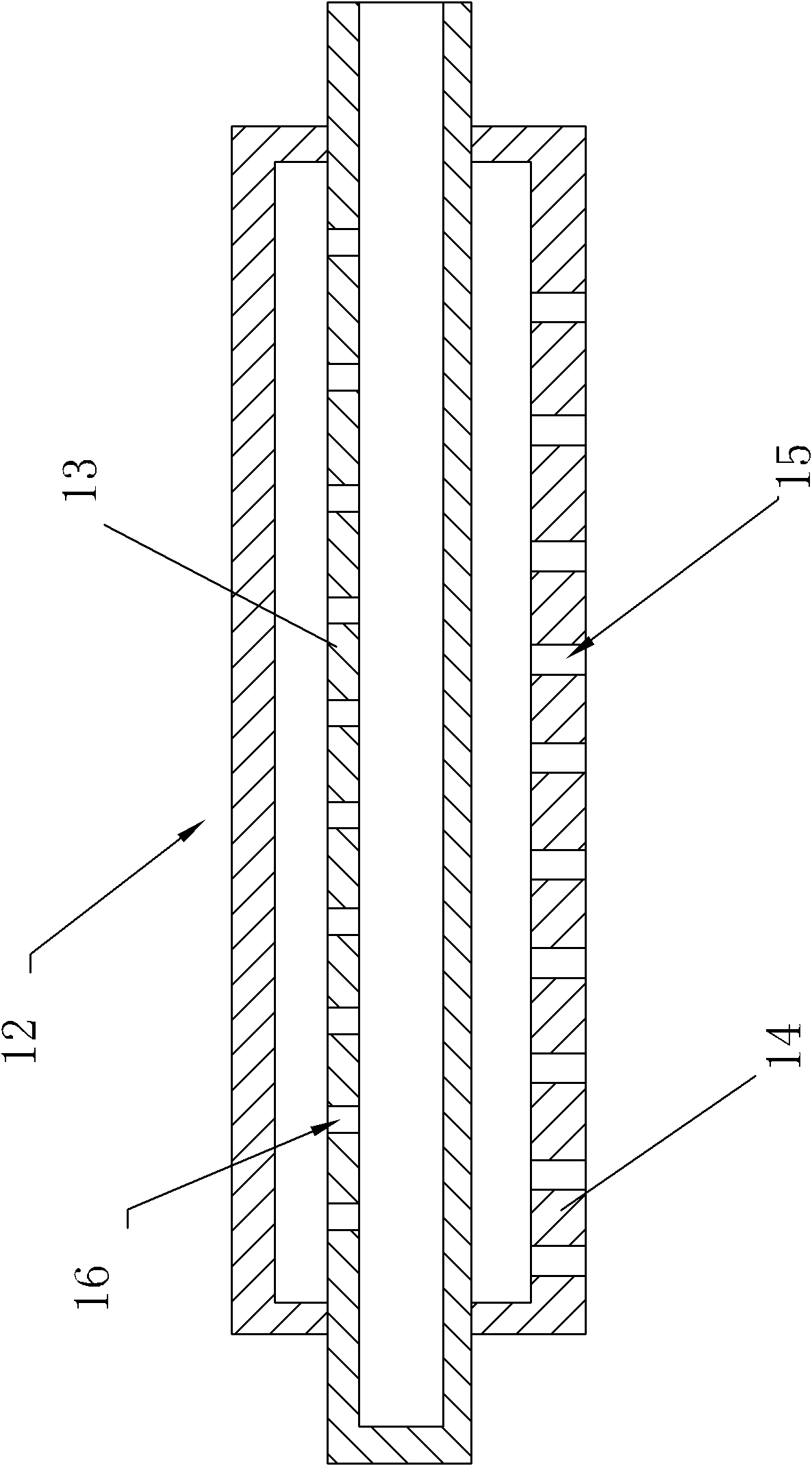

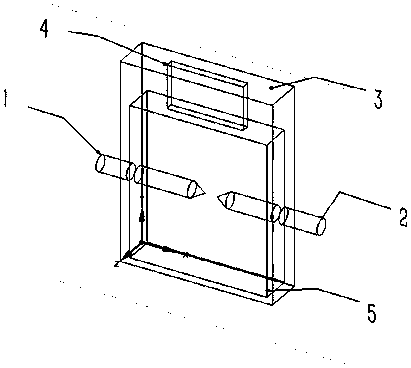

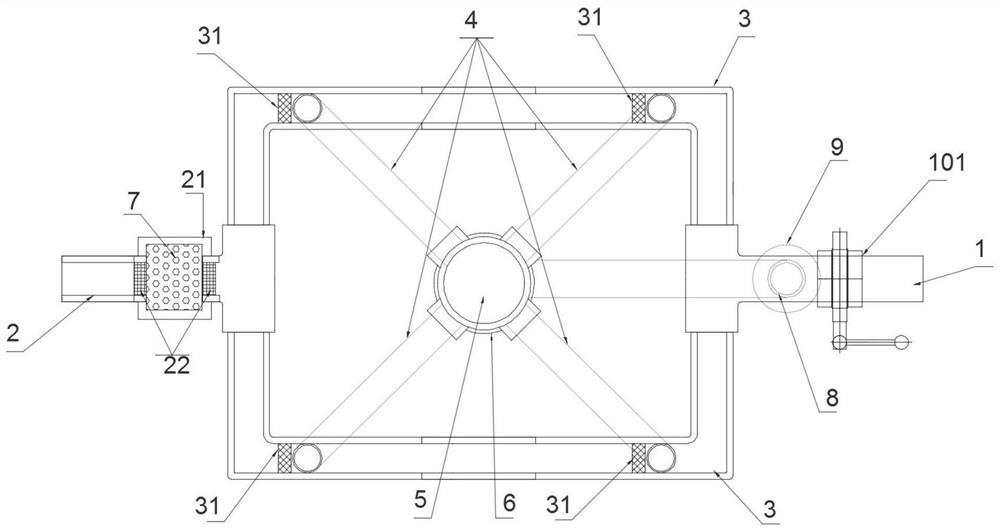

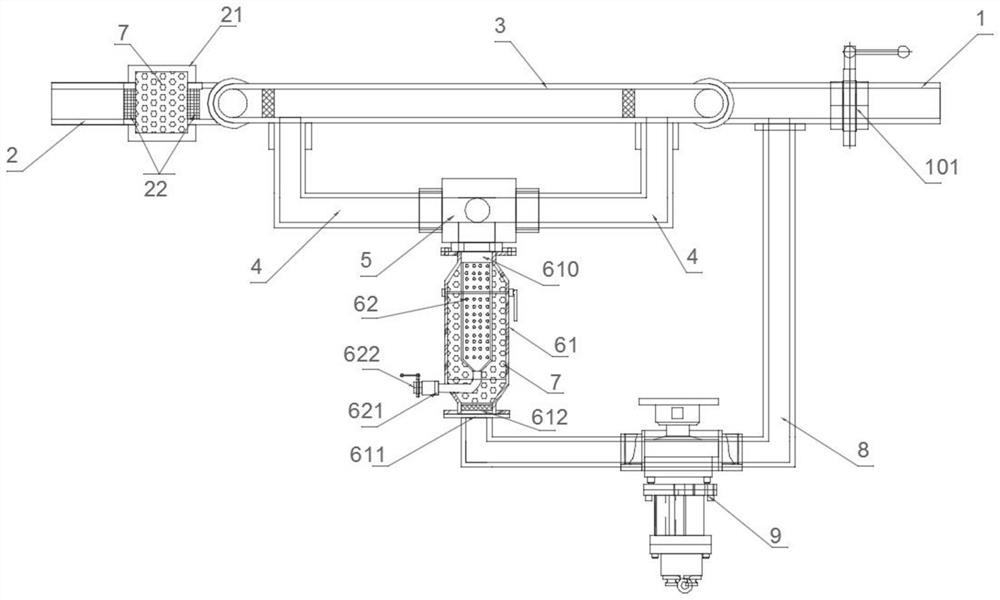

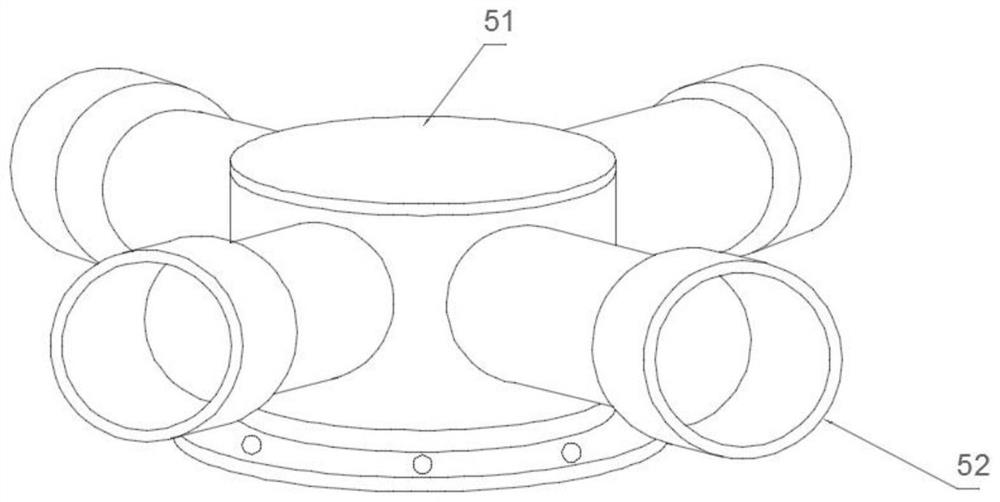

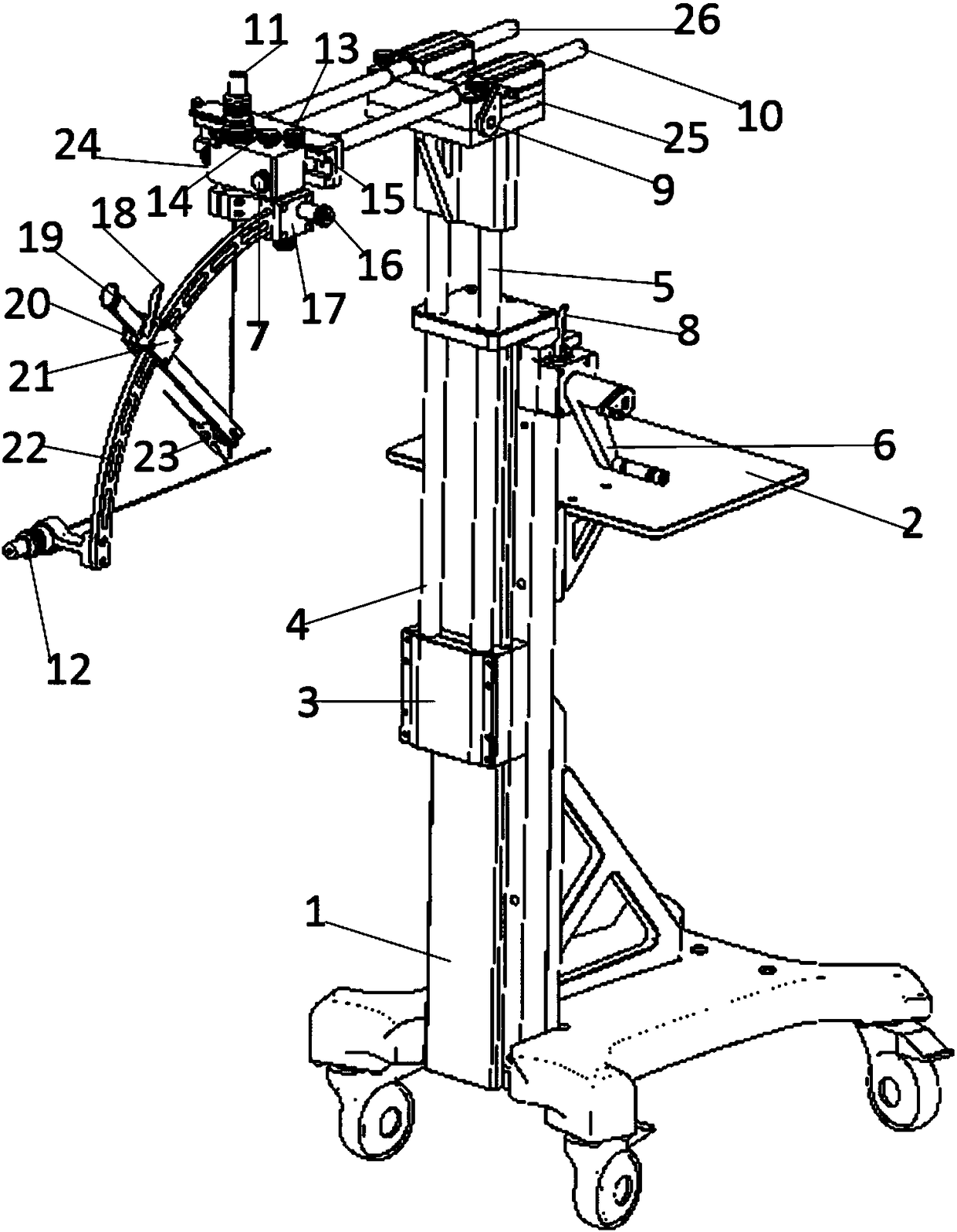

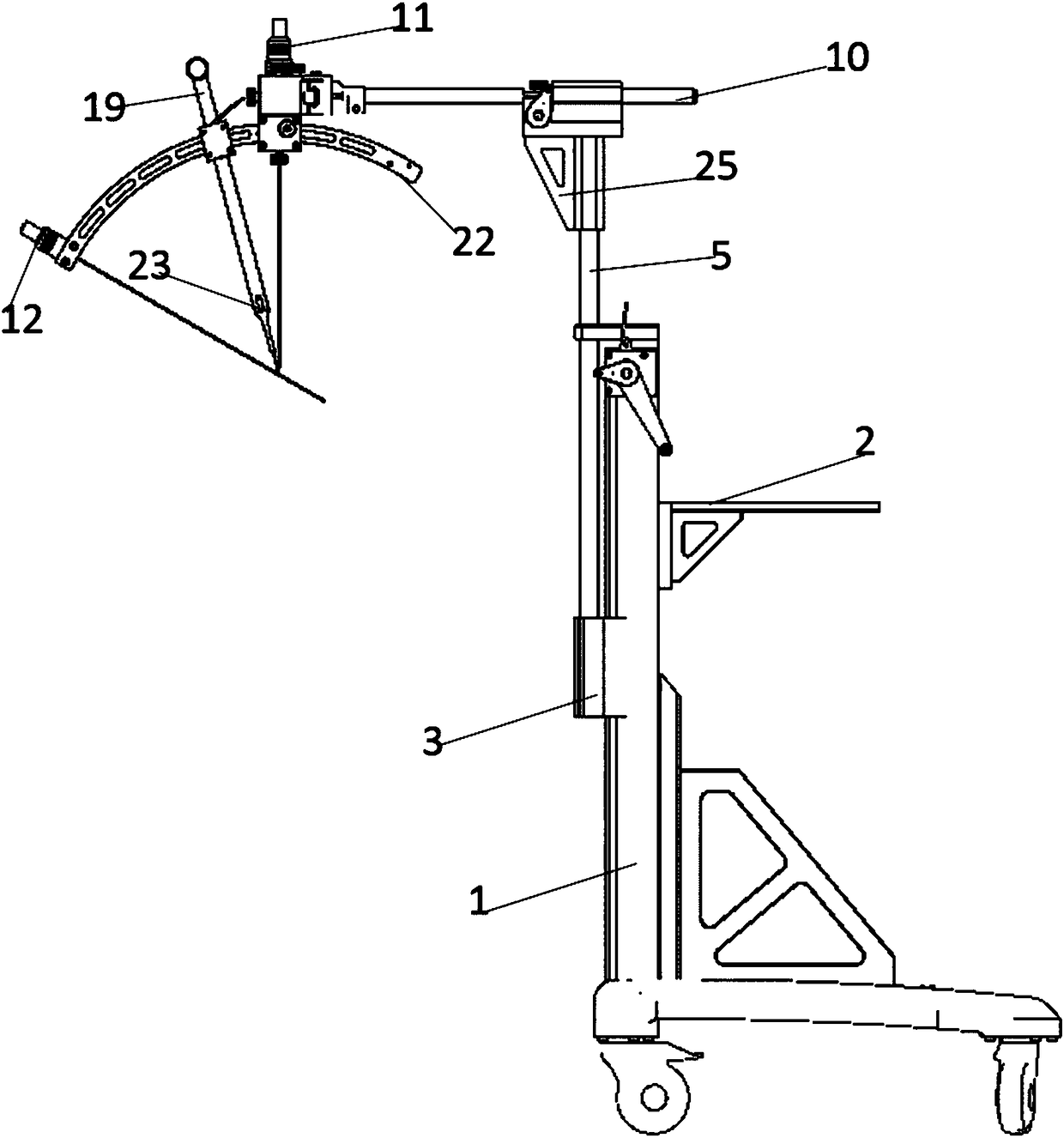

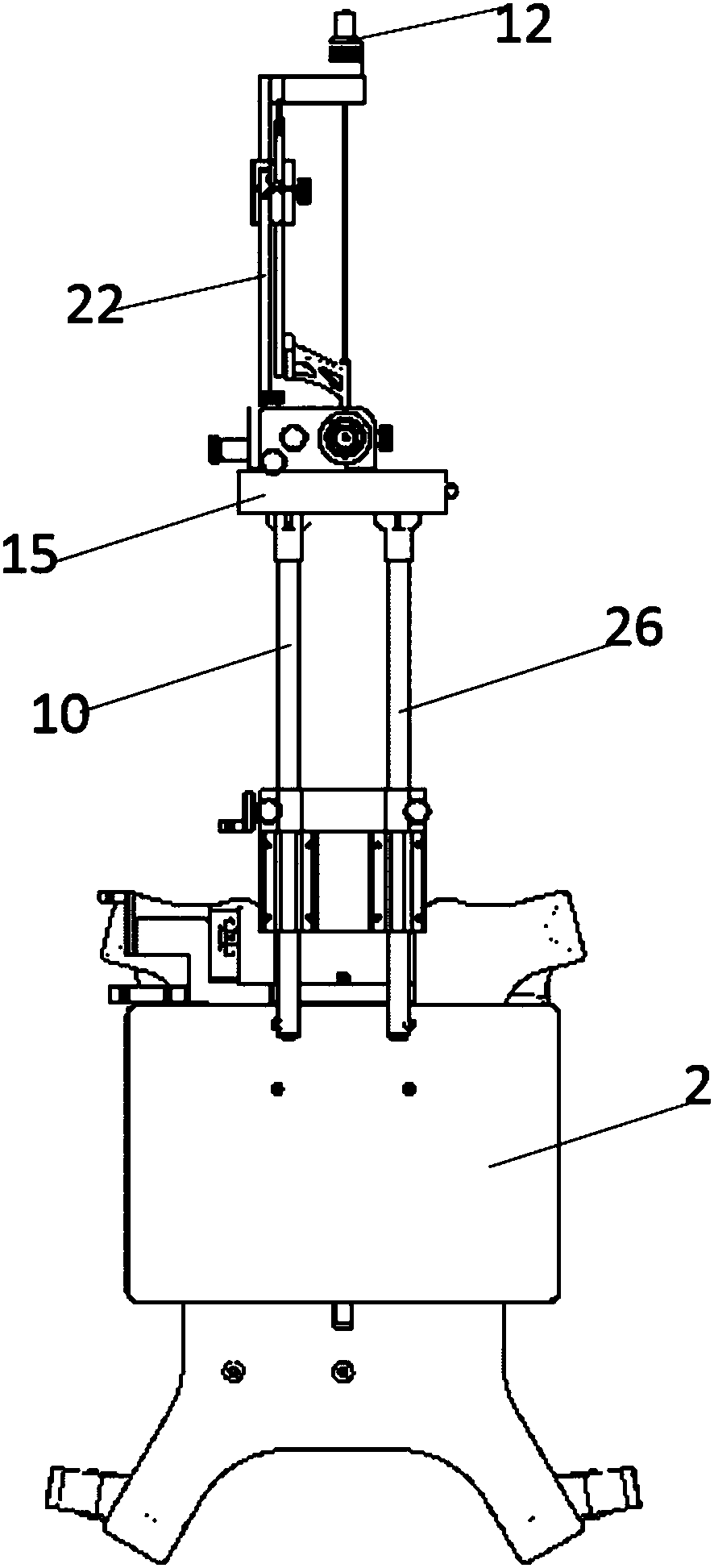

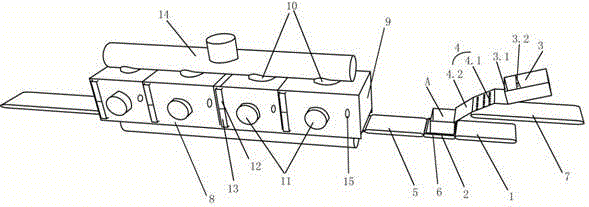

Detachable-mountable arc-shaped precise positioning equipment

ActiveCN105916463APrevent rotationIncrease operating spaceInstruments for stereotaxic surgeryLong axisEngineering

The invention relates to detachable-mountable arc-shaped precise positioning equipment, which includes a supporting unit, a three-dimensional regulating unit connected to the supporting unit, and a guidance positioning unit. The guidance positioning unit includes an arc-shaped rail, a guide rod, a holder, and positioning meters. A second sliding block is connected to the three-dimensional regulating unit; the arc-shaped rail is arranged and slides on the second sliding block, and can be subjected to in-situ rotation around a vertical axis at any angle; the three-dimensional regulating unit drives the arc-shaped rail to move in three dimensions of up-down, left-right, and front-back dimensions; the guide rod can slide along the arc-shaped rail and moves long a long axial direction of the guide rod; and the holder is arranged on the guide rod for fixing a surgical instrument. There are two positioning meters, and rays sent by the two positioning meters, along with a long axis of the holder, are parallel to or coincide with a radial line of the arc-shaped rail. The three lines are located on a same plane, which is parallel to or coincide with the plane where the arc-shaped rail is located. The three lines intersect at one point.

Owner:SHANGHAI TENTH PEOPLES HOSPITAL

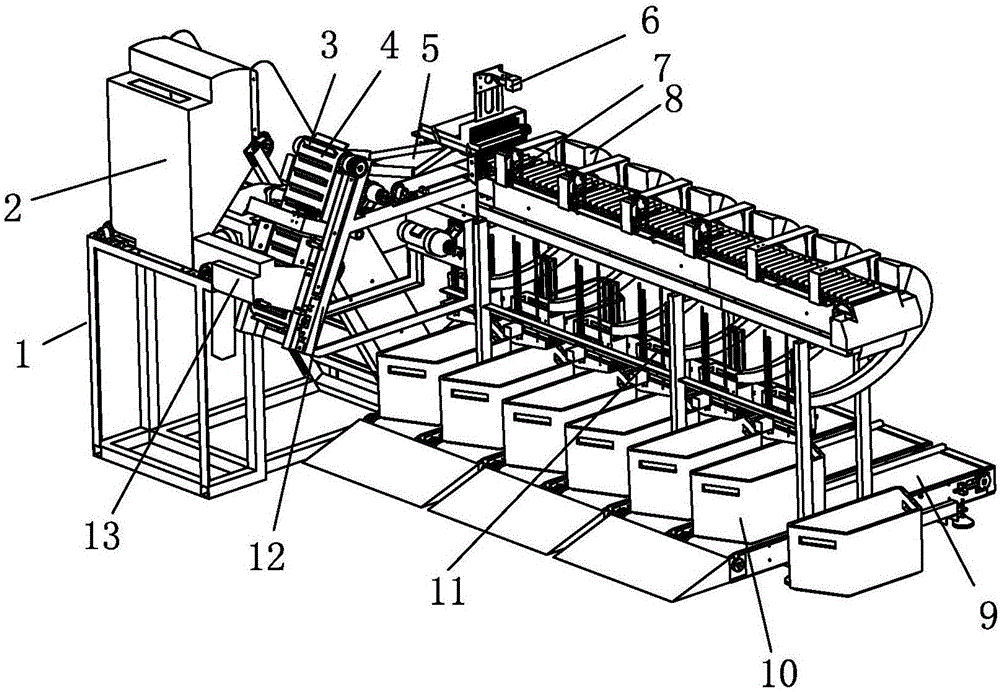

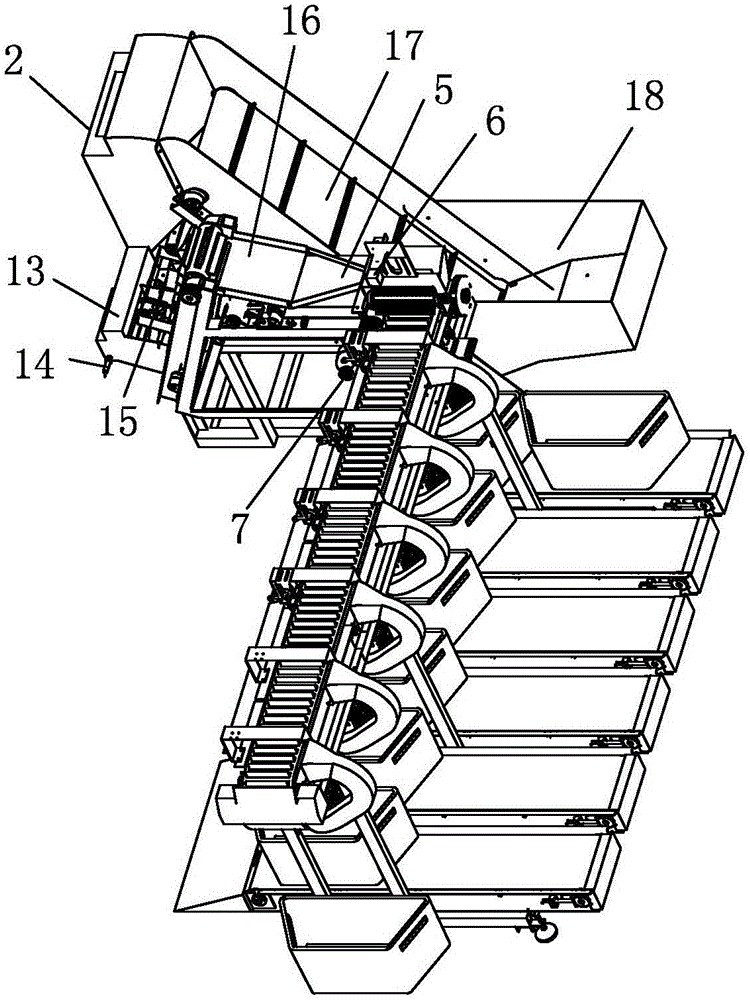

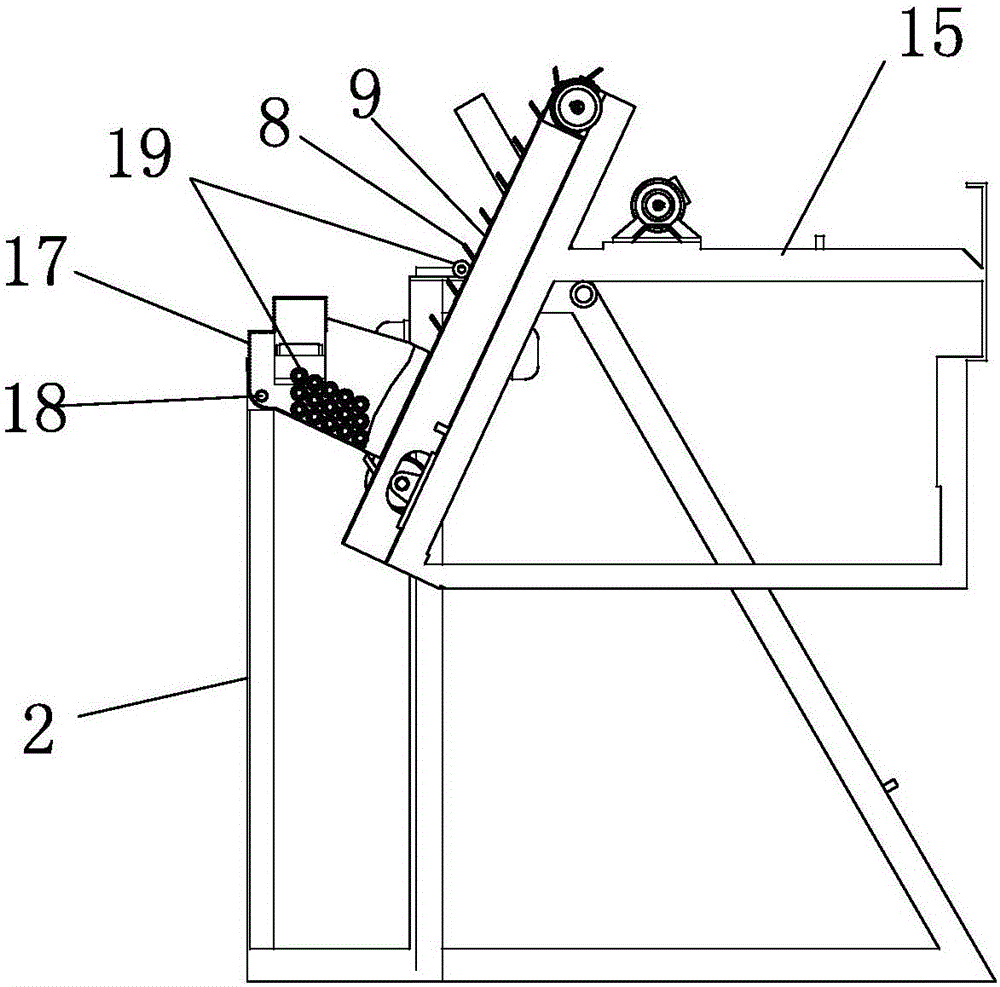

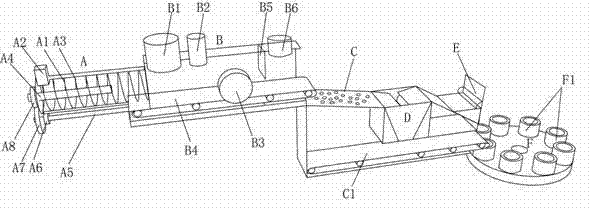

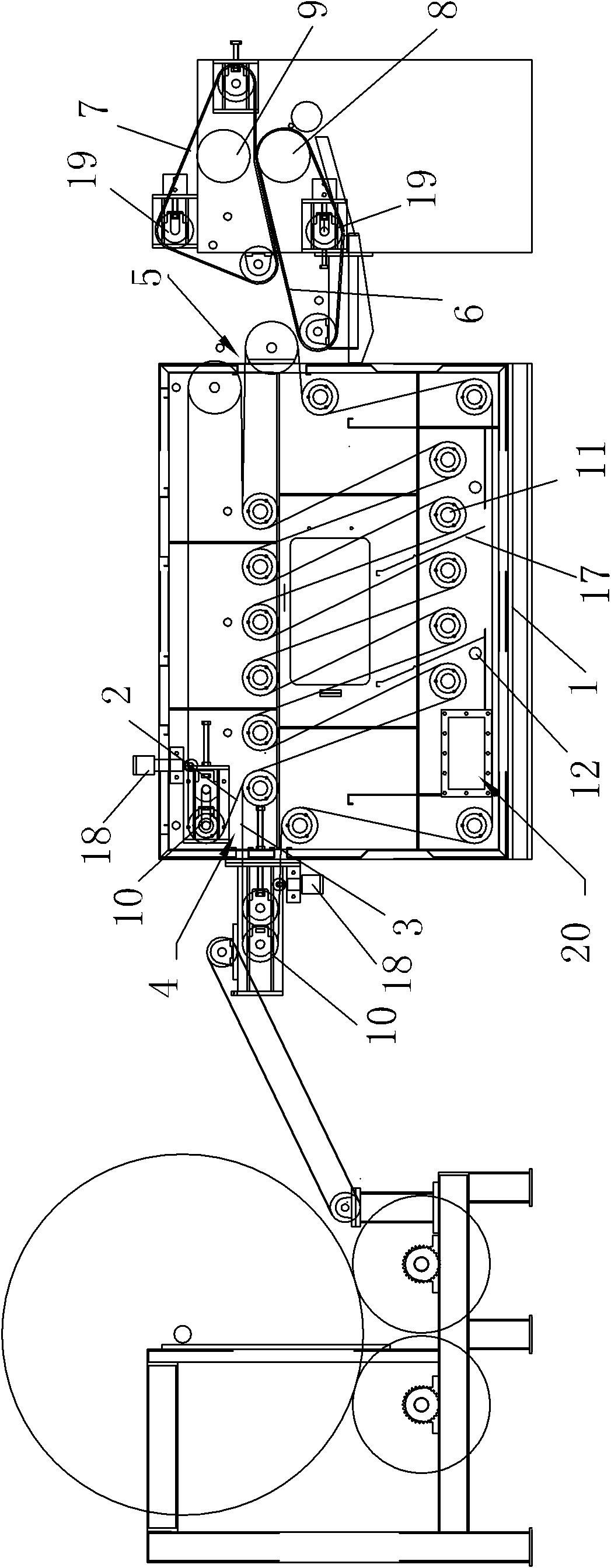

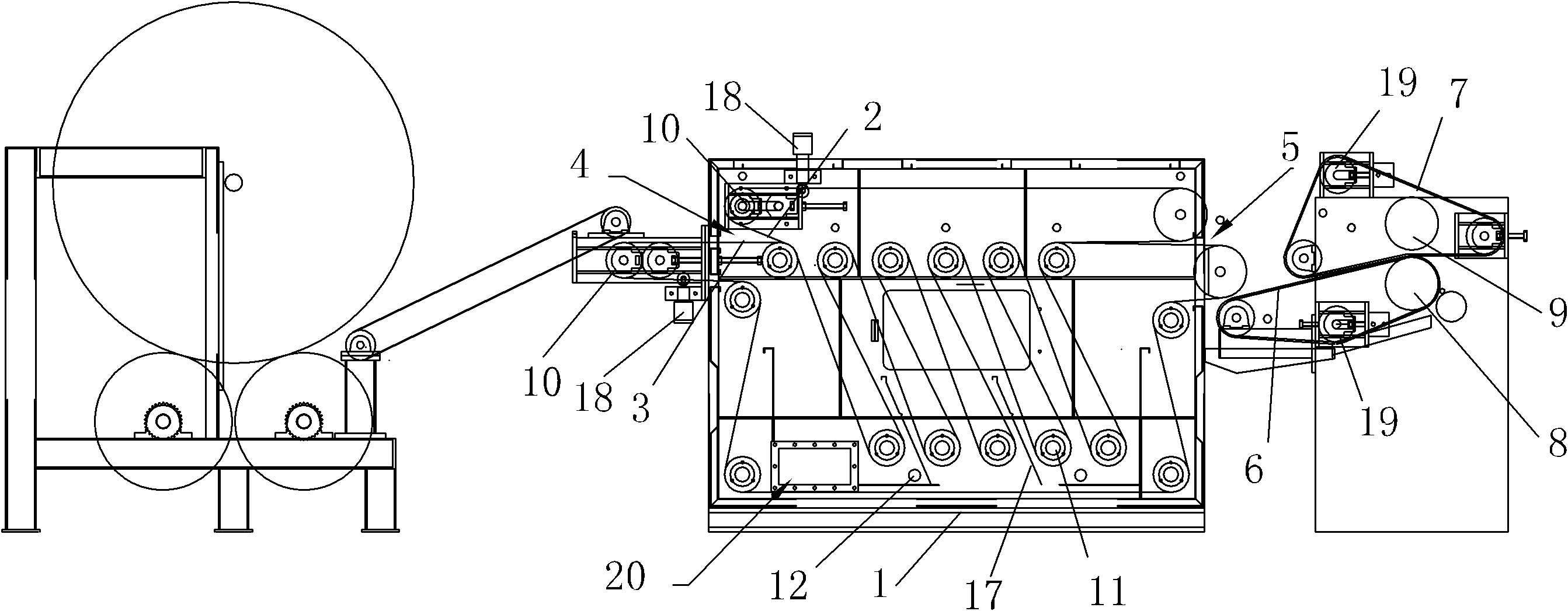

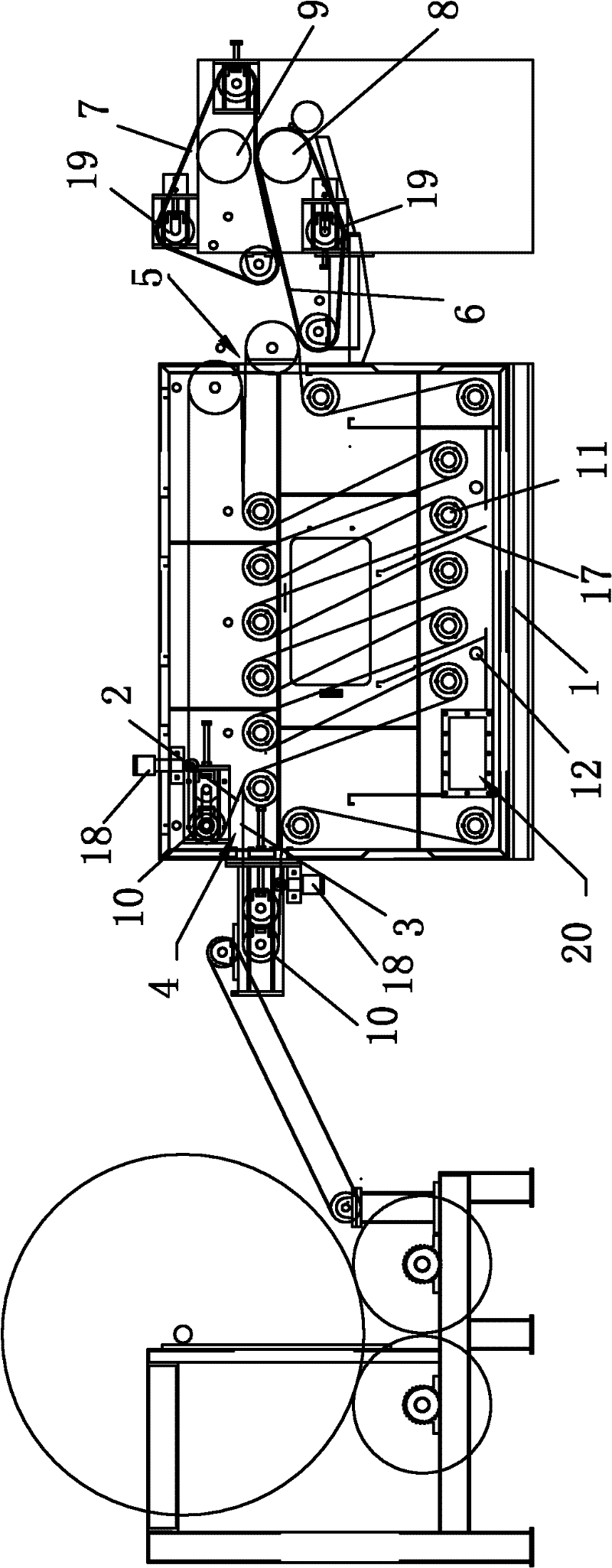

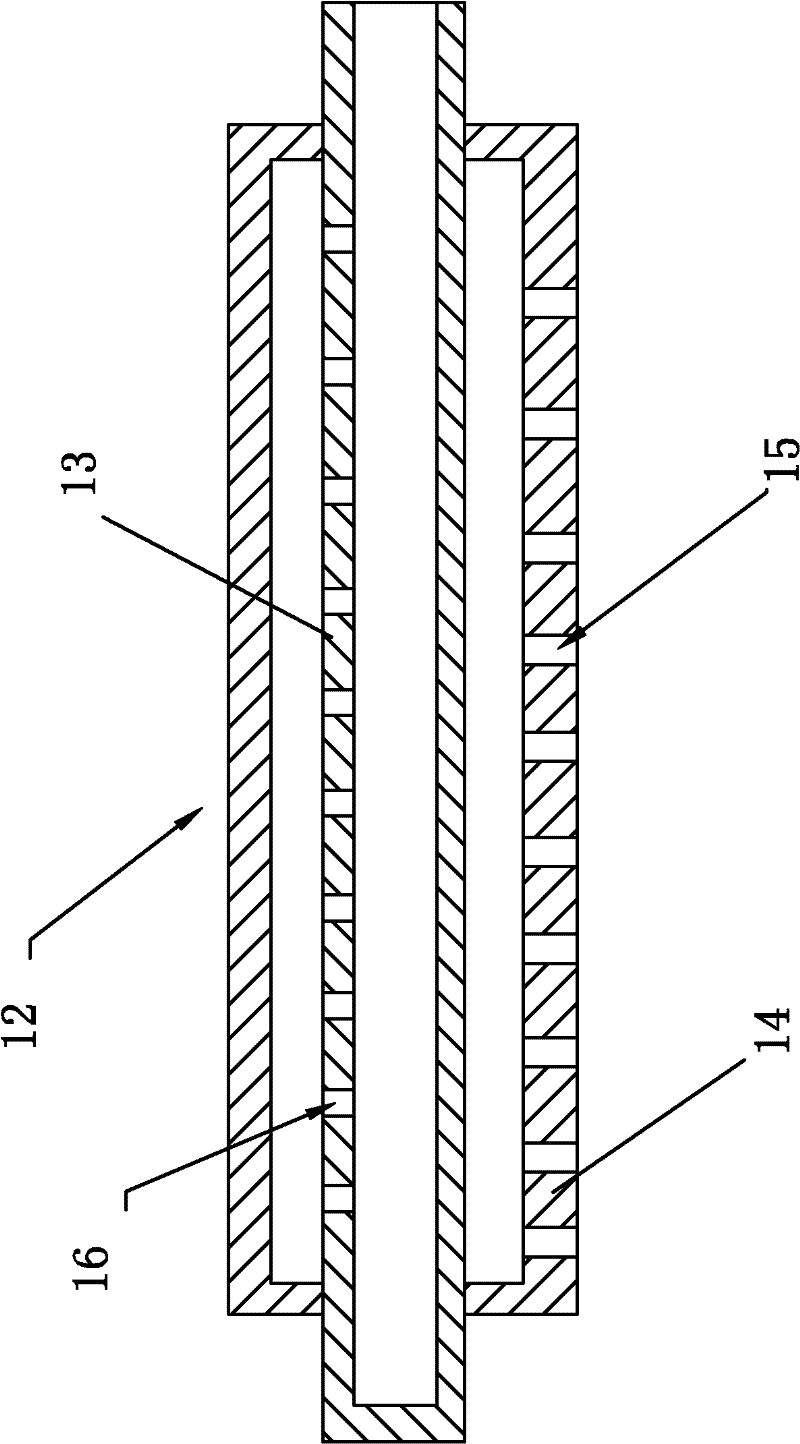

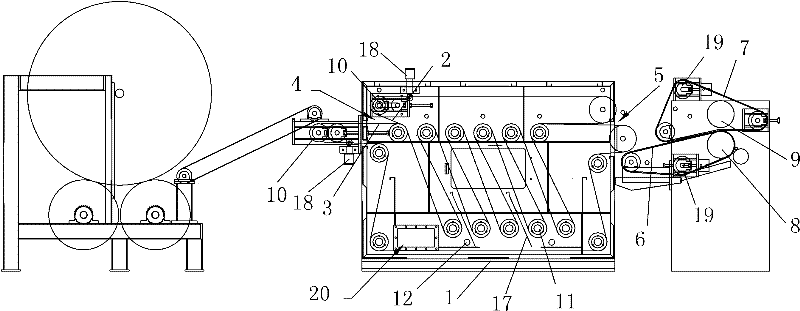

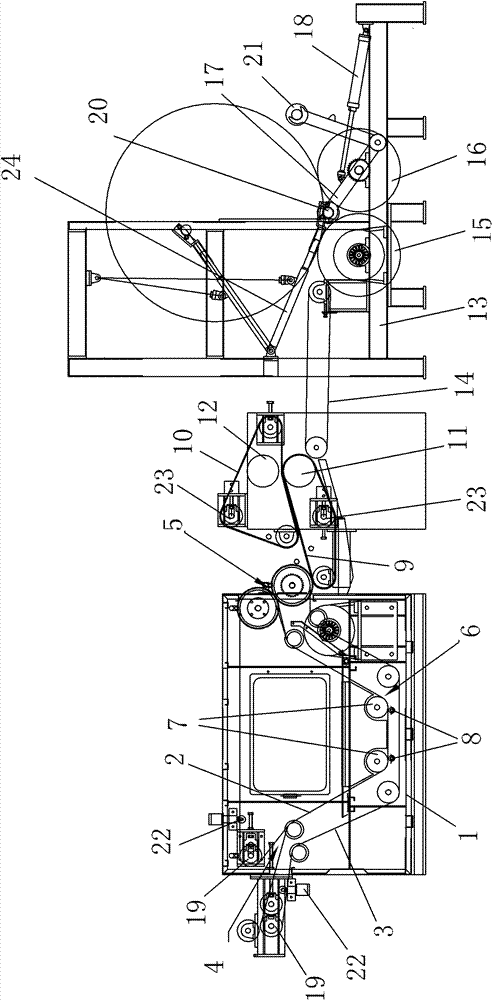

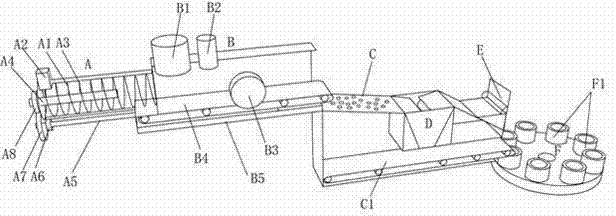

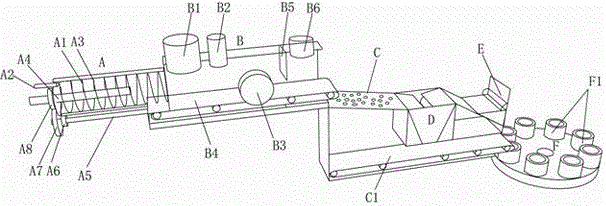

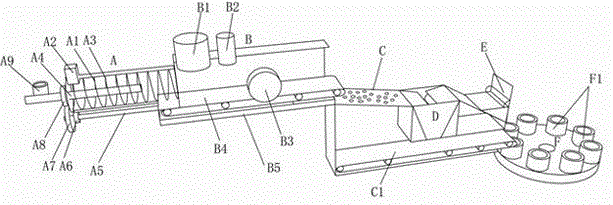

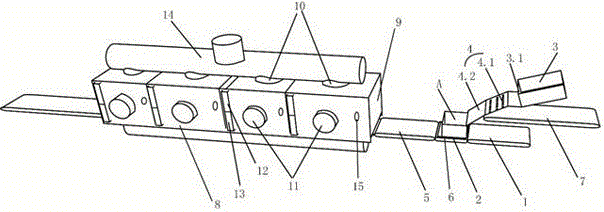

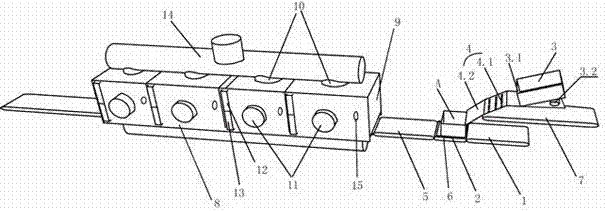

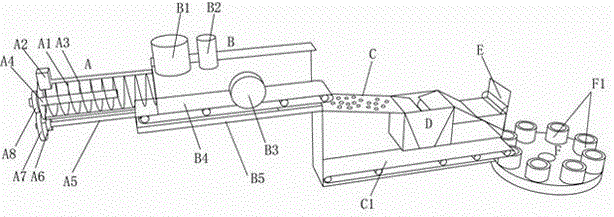

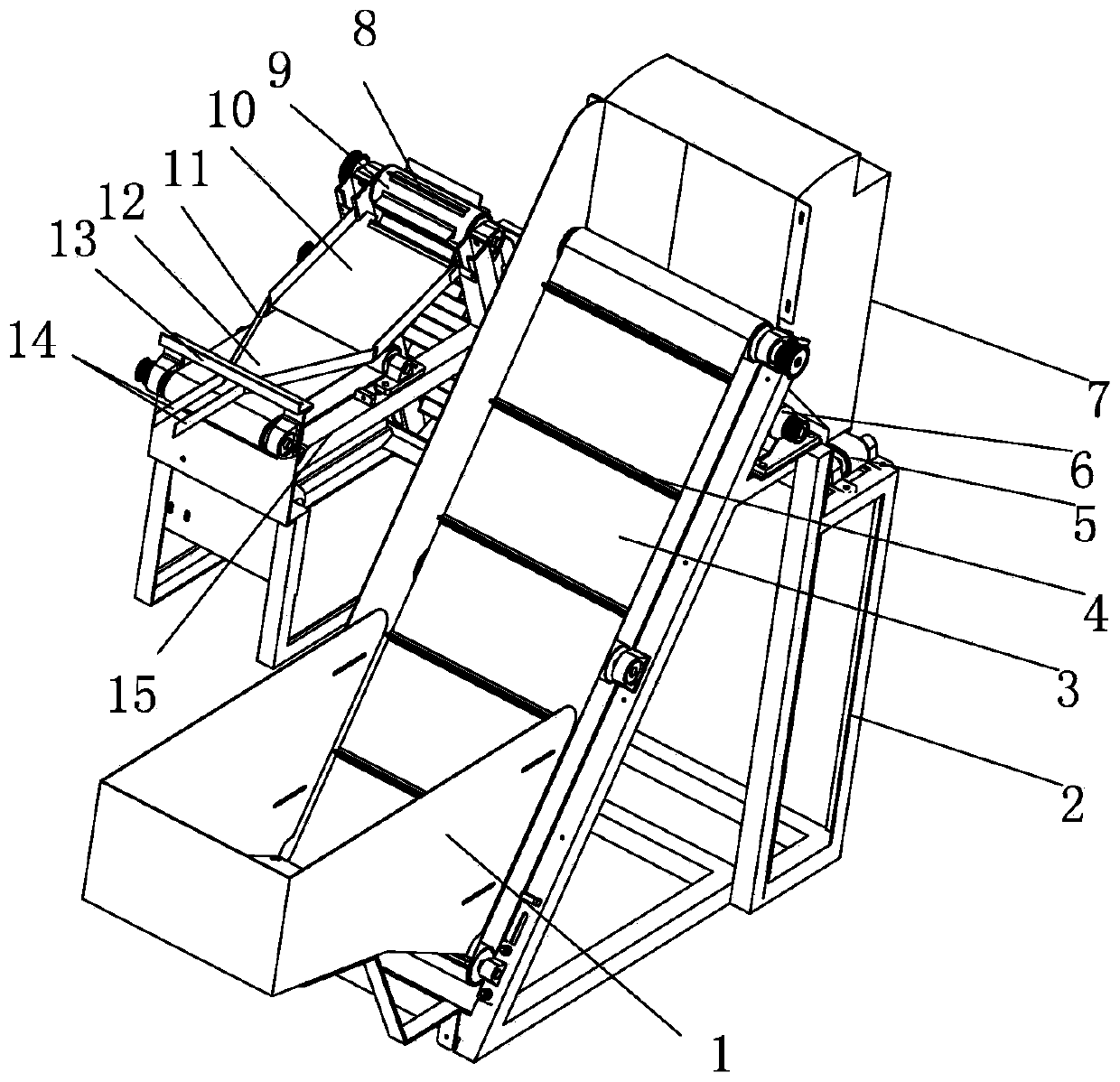

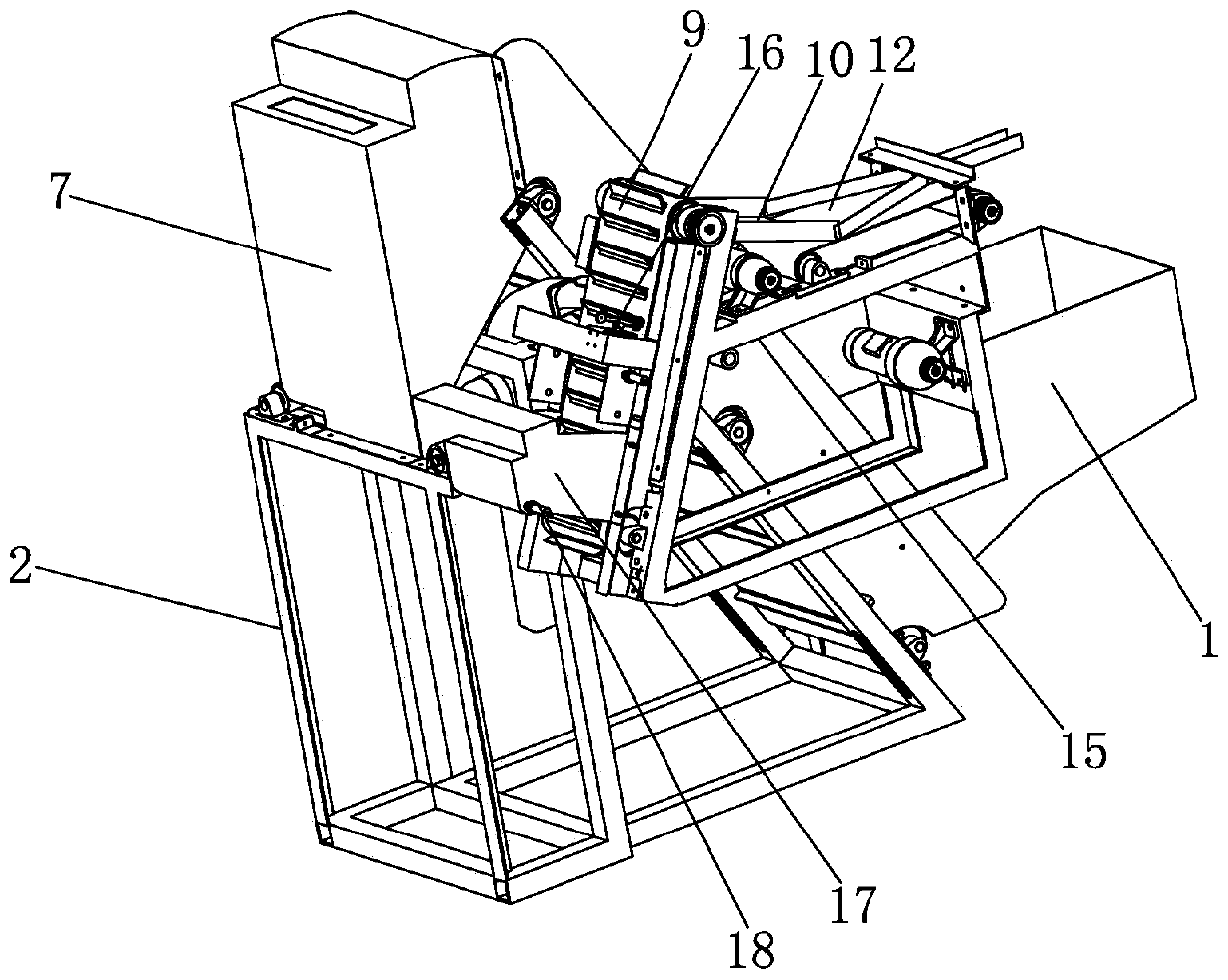

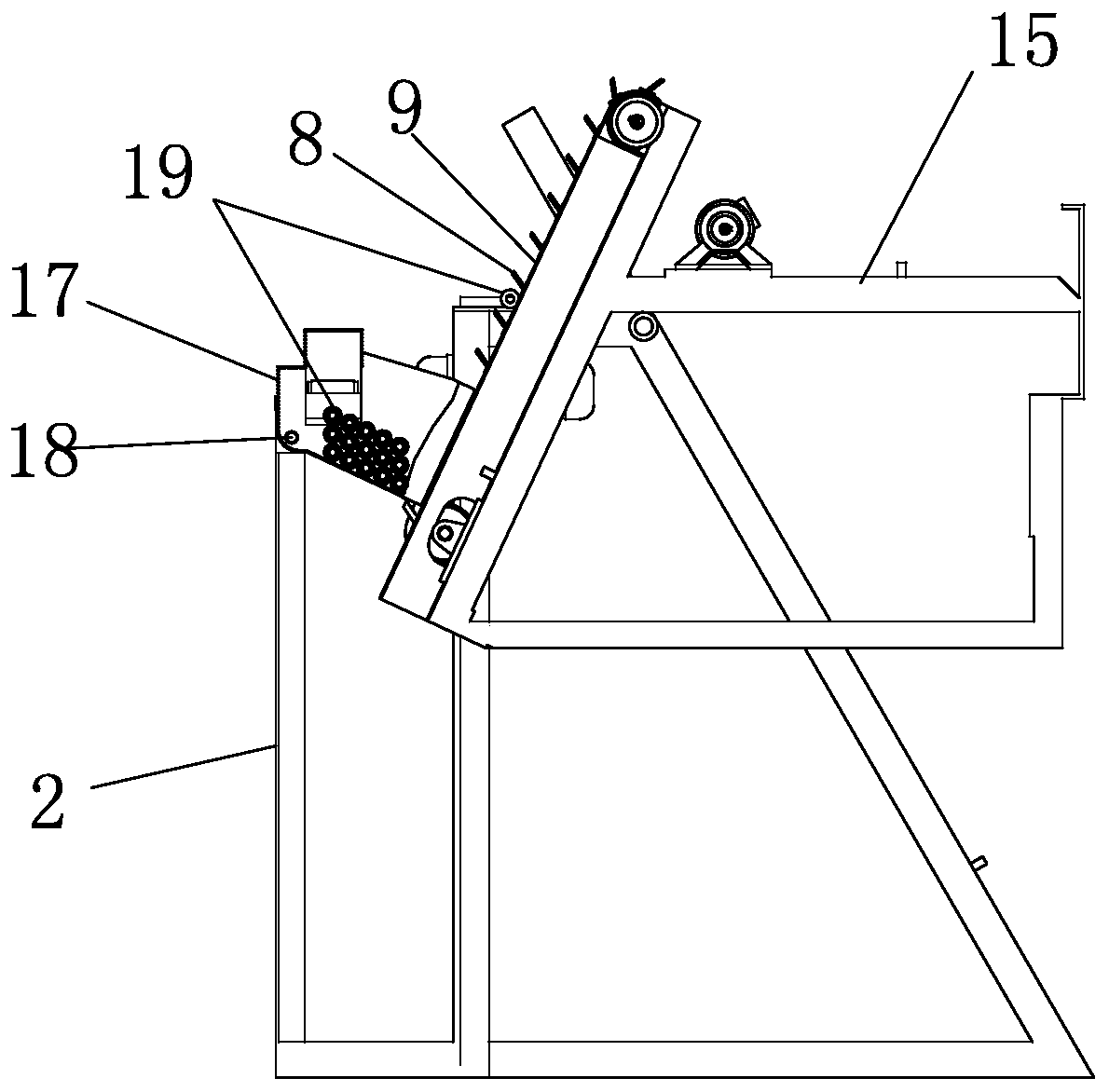

High-speed arrangement device for ring bobbins

A high-speed arrangement device for ring bobbins comprises a bobbin bin, a first-stage lifting mechanism, a bobbin straightening and conveying mechanism, a second-stage lifting mechanism, a large bobbin removal mechanism, an orientating mechanism, a color sorting system and a control system. Bobbins are lifted in two stages, so that the bobbin lifting speed is greatly increased; large bobbins with end yarns wound are accurately removed; a beating mechanism is adopted in large bobbin removal and color sorting recognition, so that handling is fast and effective. The physical principle that the rolling speed of the large ends of the bobbins is larger than that of the small ends of the bobbins is adopted in the bobbin orientating process, and when the large ends of the bobbins roll onto conveying belts, the bobbins are rapidly pulled to a next process, so that the function of rapidly arranging and orientating bobbins is achieved. Through modular management of color sorting execution mechanisms, various bobbins in different colors can be recognized, so that the use effect is improved. Through a bobbin smoothening and placing mechanism and a casing, arraying and conveying mechanism, the bobbins with the color recognized are orderly arrayed, cased and conveyed, and empty case replacement is automatically carried out, so that full-automatic bobbin arrangement is achieved.

Owner:ZHEJIANG ZILI MACHINERY

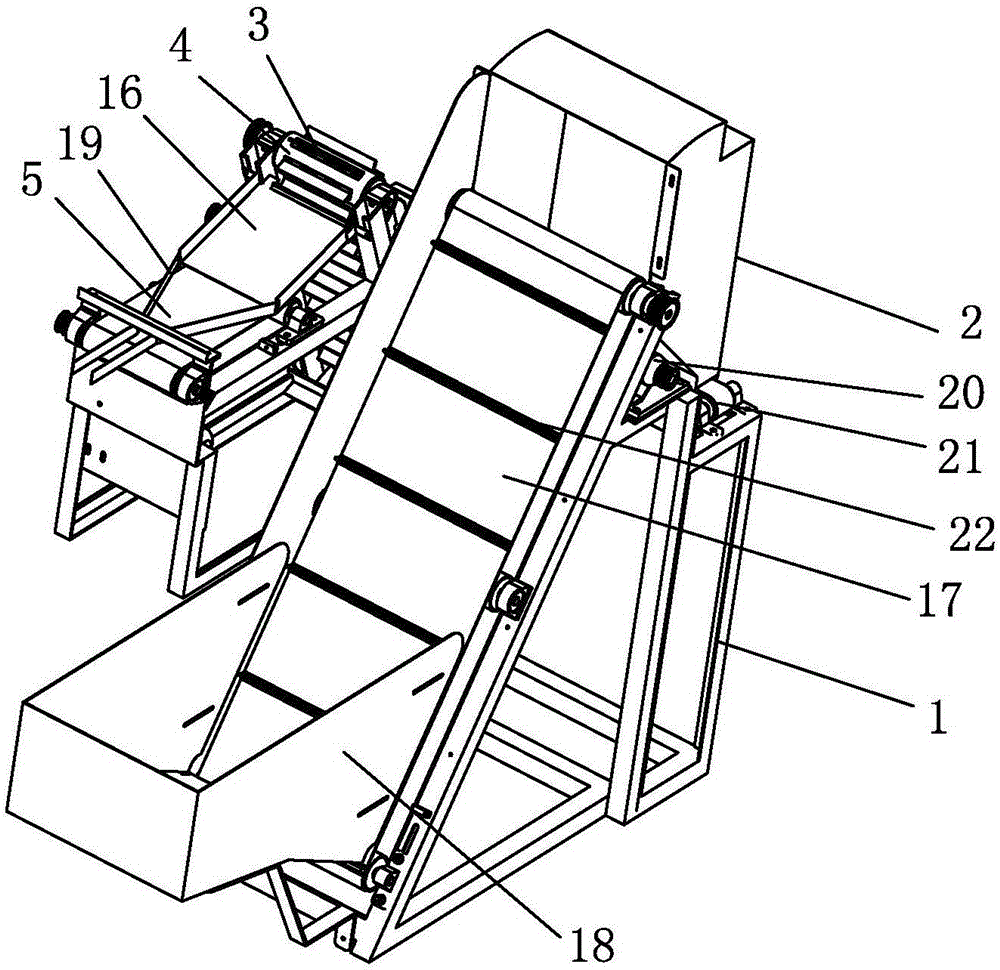

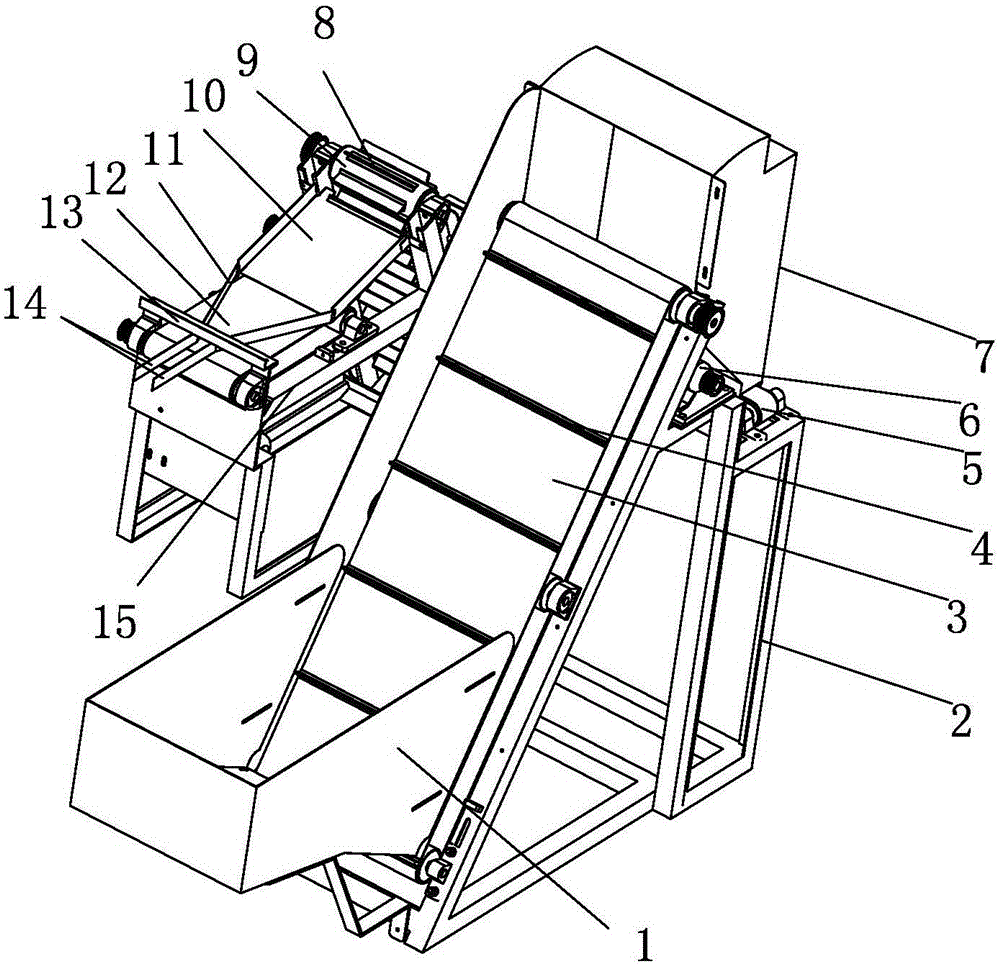

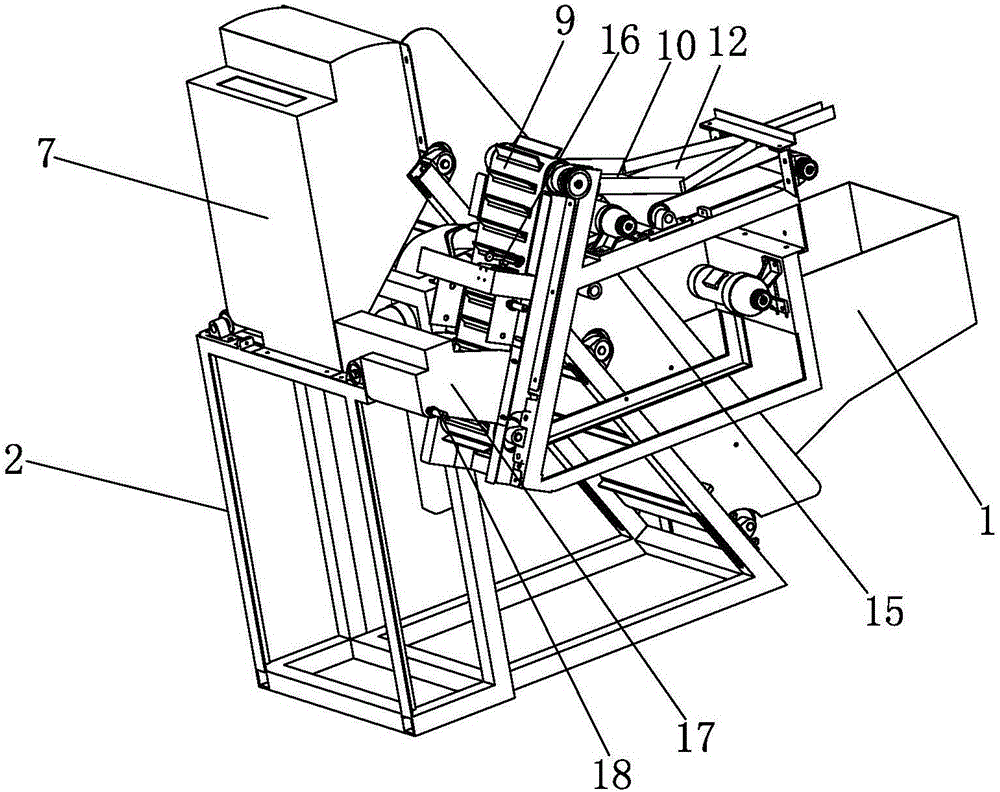

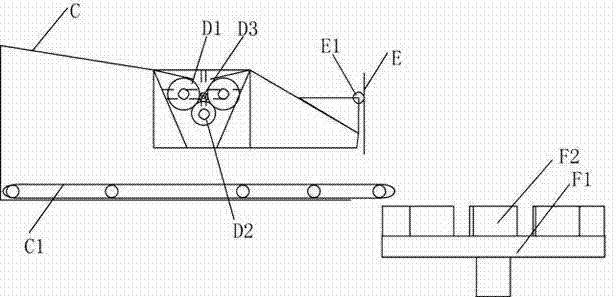

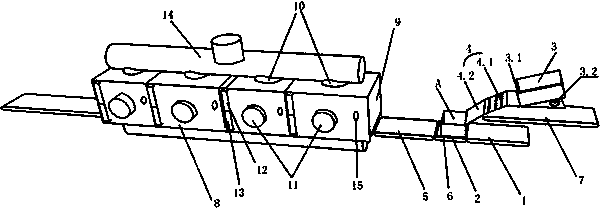

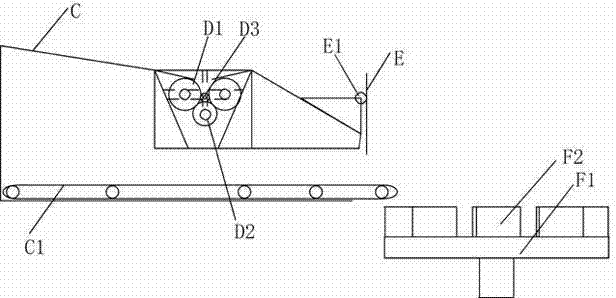

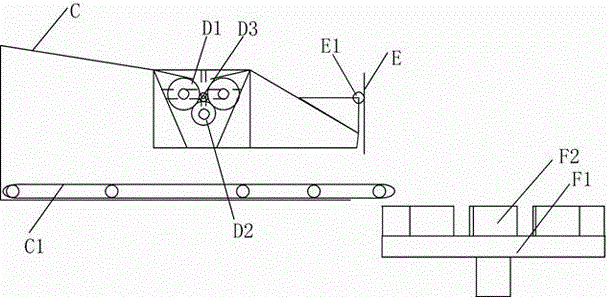

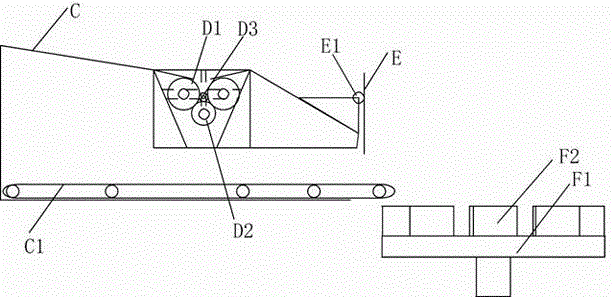

Directional bobbin conveying device of bobbin arranging machine

ActiveCN106256721AHigh speedSolve the function of quick sorting and orientationConveyorsConveyor partsYarnBobbin

The invention belongs to the technical field of textile machines, and discloses a directional bobbin conveying device of a bobbin arranging machine. The directional bobbin conveying device comprises a bobbin bin, a first-stage lifting mechanism, a bobbin straightening conveying mechanism, a second-stage lifting mechanism, a large bobbin removing mechanism and a directional mechanism. Bobbins are lifted in two stages through the first-stage lifting mechanism and the second-stage lifting mechanism, so that the bobbin lifting speed is greatly increased; besides, the bobbins are directionally conveyed at a constant speed, so that the bobbin arranging efficiency is improved. Large bobbins with end yarns wound are accurately removed in the lifting process, and a beating mechanism is adopted in the large bobbin removing process, so that compared with an air cylinder structure, the handling speed is greatly increased, and the structure is simple. The physical principle that the rolling speed of the large ends of the bobbins is larger than that of the small ends of the bobbins in the directional bobbin conveying process is utilized, and an optimized angle is adopted to make the bobbins roll at the maximum angle without sliding relative to a directional roller path, so that the bobbins are rapidly pulled to a next process when the large ends of the bobbins roll onto conveying belts, and the function of rapidly and directionally arranging bobbins is achieved.

Owner:ZHEJIANG ZILI MACHINERY

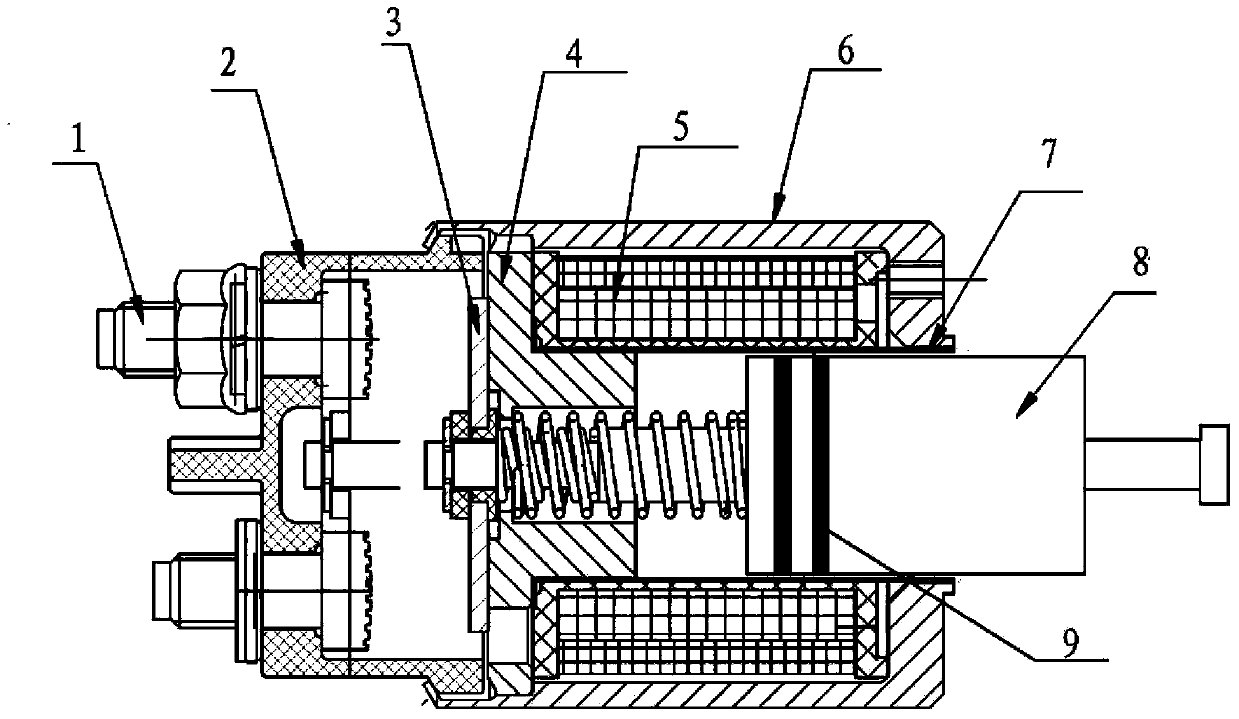

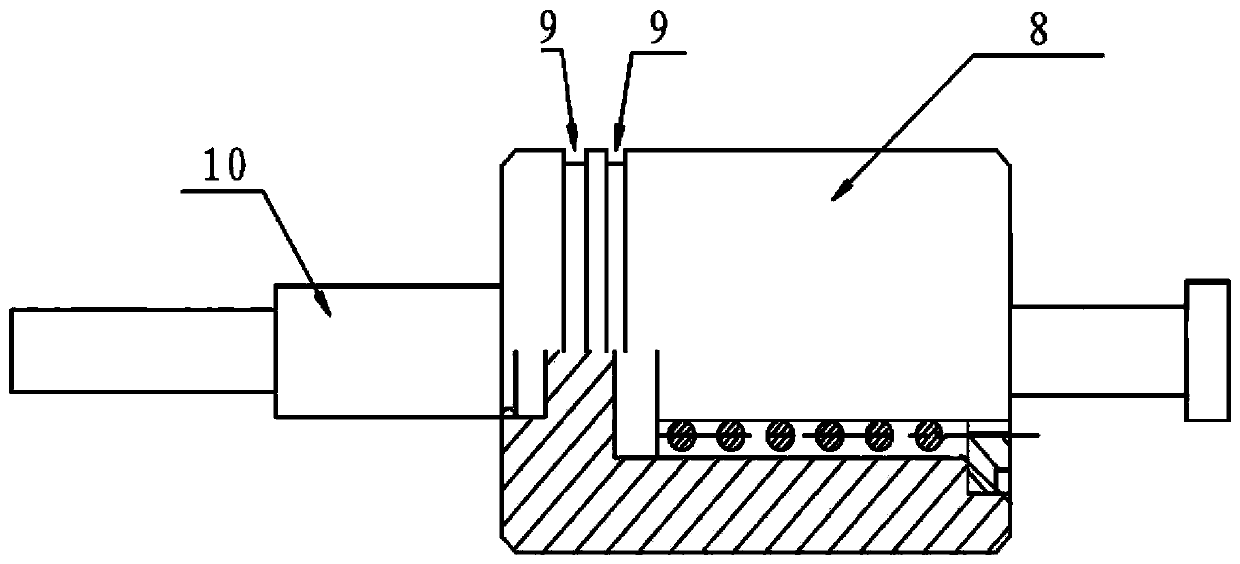

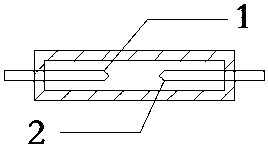

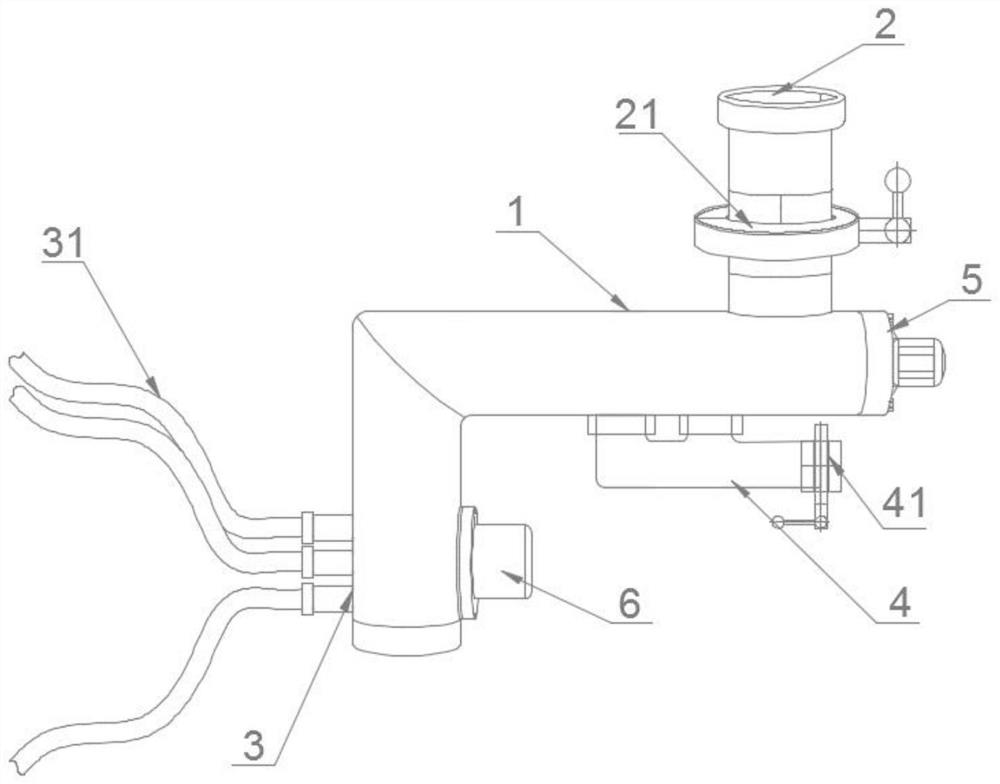

Starter electromagnetic switch with waterproof structure

InactiveCN103745885AAchieve sealingImprove waterproof performanceElectromagnetic relay detailsElectromagnetic coilLabyrinth seal

The invention discloses a starter electromagnetic switch with a waterproof structure. The starter electromagnetic switch comprises a switch shell, wherein an electromagnetic coil is arranged in the switch shell; a hollow spool chamber is arranged in the switch shell; a spool component is in sliding fit in the spool chamber; one end of the spool component is connected with a reset piece; the other end of the reset piece is connected with a contact plate. The starter electromagnetic switch is characterized in that the spool component is at least provided with a groove, so that the spool component and the spool chamber form a labyrinth seal. By a labyrinth seal structure, the electromagnetic switch is sealed; the grooves are filled in a mode of adding waterproof grease in two grooves; compared with the traditional electromagnetic switch, the starter electromagnetic switch has the advantage that the waterproofness is improved by more than 50 percent; the starter electromagnetic switch has outstanding substantial effects and remarkable progress.

Owner:LIUZHOU GENERATOR AUTOMOTIVE ELECTRICAL SYST MFR

Method for promoting light oil yield of atmospheric and vacuum distillation of petroleum oil

InactiveCN100348695CImprove light oil yieldNo need to change the structureHydrocarbon distillationAcetic acidOrganic solvent

The invention relates the method for improving atmospheric and vacuum distillation light oil productivity. The method comprises the following step: adding the 0.001-0.1wt% addition agent with colophony into crude oil in atmospheric and vacuum distillation tower. The addition agent comprises 50-80% colophony and 50-20% organic solvent. The pH is 7.0-7.5. The organic solvent comprises ethanol or cellosolve or ethyl propyl acetone or acetate cellosolve. The method can be used in oil-extraction plant, and the light oil productivity is improved by 1.5-2.3wt%.

Owner:SHANGHAI JIAO TONG UNIV

Automatic compound fertilizer granulation assembly system

ActiveCN103694064AAchieve granulationAchieve dryingGranulation in rotating drumsFertiliser formsEconomic benefitsAgricultural engineering

The invention discloses an automatic compound fertilizer granulation assembly system which comprises a granulator and a drier connected with the granulator. The system is characterized in that the granulator comprises a rotating drum, wherein the top of the rotating drum is provided with a feed port, the middle of the rotating drum is provided with a worm transmission part, the position with the same center of circle as the worm transmission part in the rotating drum is provided with a rotary sprayer, and the rotating drum and the rotary sprayer are driven to rotate by the same power source. The system has the advantages of ingenious and reasonable design and high systematicness; by arranging the multistage equipment, the system can effectively implement the functions of granulating, drying screening and assembling the compound fertilizer, has high degree of automation and superior performance; and compared with the existing split equipment, the efficiency is enhanced by more than 40%, and the economic benefit is enhanced by more than 30%.

Owner:河北百斗嘉肥料有限公司

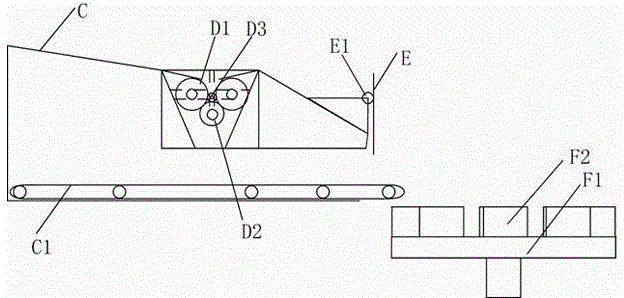

Continuous loose fiber cleaning machine

InactiveCN101954357AUniform temperatureHighlight the substantive effectCleaning using liquidsFiberEngineering

The invention relates to a continuous loose fiber cleaning machine comprising a plurality of groups of cleaning units, cleaning tanks arranged in each group of cleaning units and conveying mechanisms matched with the cleaning tanks, wherein each conveying mechanism comprises a dual mesh belt cleaning and conveying mechanism which comprises a closed annular mesh belt A, a closed annular mesh belt B and a driving assembly which is respectively in driving fit with each cleaning mesh belt; two annular cleaning mesh belts positioned in the cleaning tanks are in clearance overlapping fit; the two annular cleaning mesh belts respectively form a duck bill input port and a duck bill output port at the inlet port and the outlet end of the cleaning tank; and two annular cleaning mesh belts positioned outside the cleaning tank are respectively matched with the driving assembly to form annular driving. The invention has the predominant substantial effect: the tiled loose fibers are clamped by the dual mesh belt cleaning and conveying mechanism, enter the cleaning tanks and are easy to clean; in addition, cotton sequentially enters each cleaning tank and can be cleaned more thoroughly.

Owner:新昌县艺力机械有限公司

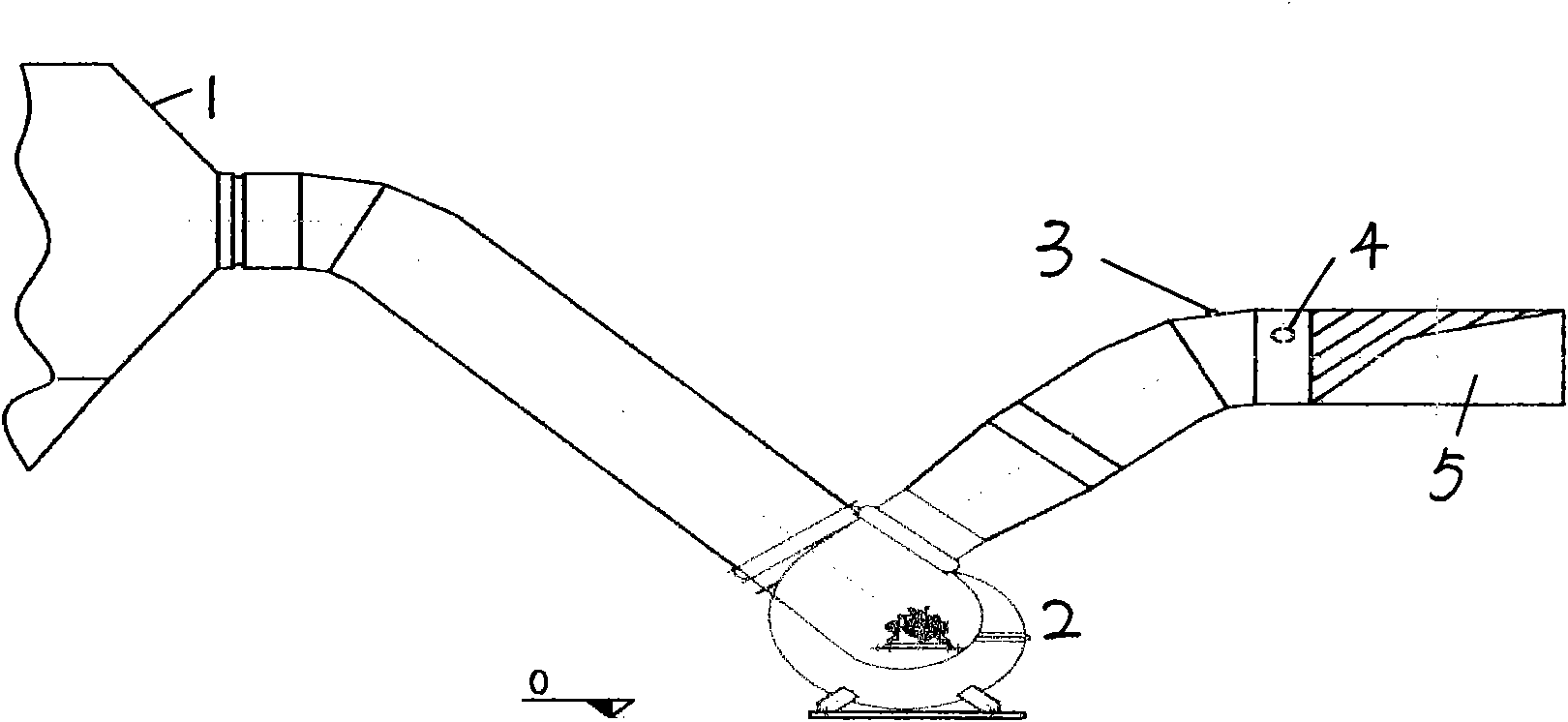

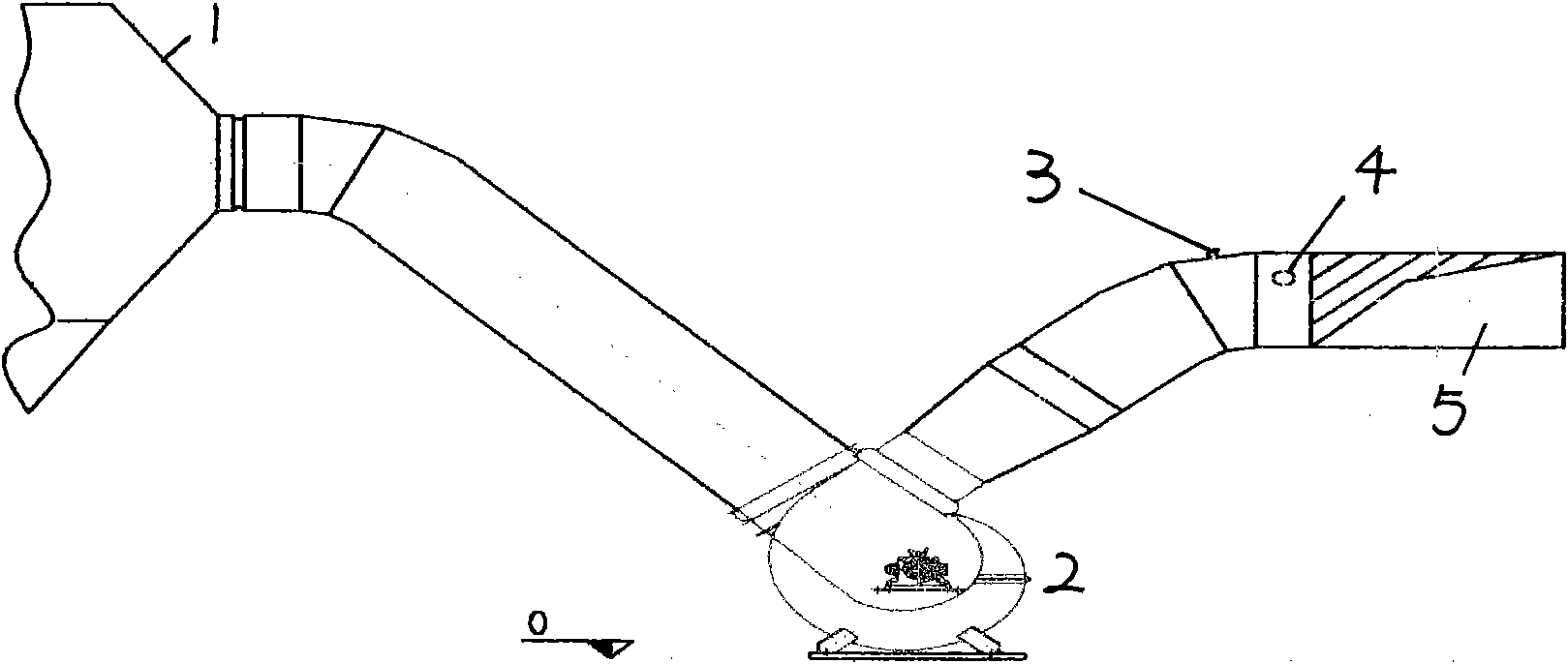

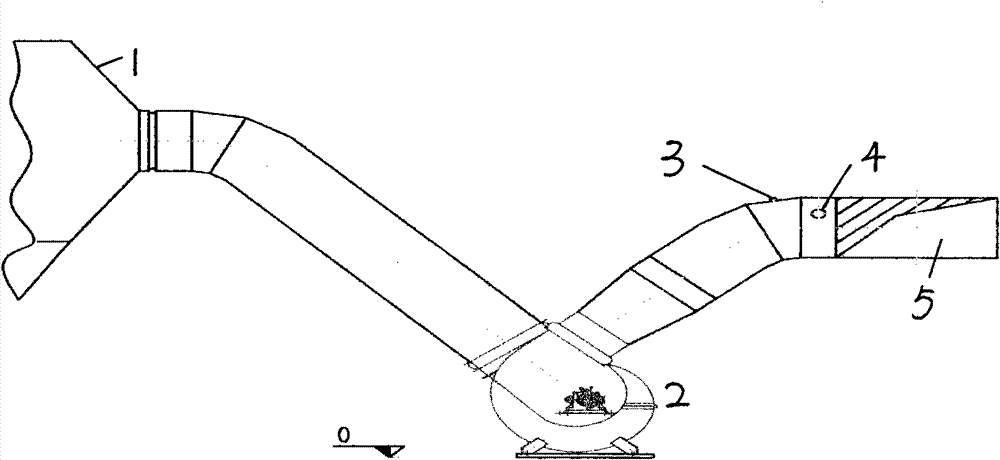

Combined type synthetic jet actuator utilizing piezoelectric vibrating diaphragm and two-electrode plasma

PendingCN108223500ASolve the problem of too low speedFlexible useCircuit elementsElectricityJet flow

The invention discloses a combined jet actuator utilizing a piezoelectric vibrating diaphragm and a two-electrode plasma. The actuator comprises an exciter body, a piezoelectric vibrating thin film 5,a cover plate 3, an outlet seam 4 and an ignition positive pole 1, an ignition negative electrode 2 and an external pulse power supply, wherein a cavity is formed in the exciter body, during operation, the positive and negative electrodes connected to the two sides of the cavity of the actuator break down air to discharge, and the air in the discharge cavity is heated instantly; and the high-pressure plasma formed in the cavity of the actuator is under the combined action of the piezoelectric vibration thin film 5 through the outlet seam 4 is sprayed out at a high speed from an opening in thecover plate to form a high-speed jet flow. The problems that the jet speed is too low due to the piezoelectric vibration type actuator, the high-frequency plasma synthetic jet actuator is prone to causing accumulation of energy in the cavity, the temperature is too high and even exceeds the maximum limit of materials are solved, so that the synthesis jet speed can be increased, the temperature inthe cavity can be effectively reduced, meanwhile, the backfilling rate of the gas is increased, and the utilization efficiency of energy is improved.

Owner:NANJING UNIV OF SCI & TECH

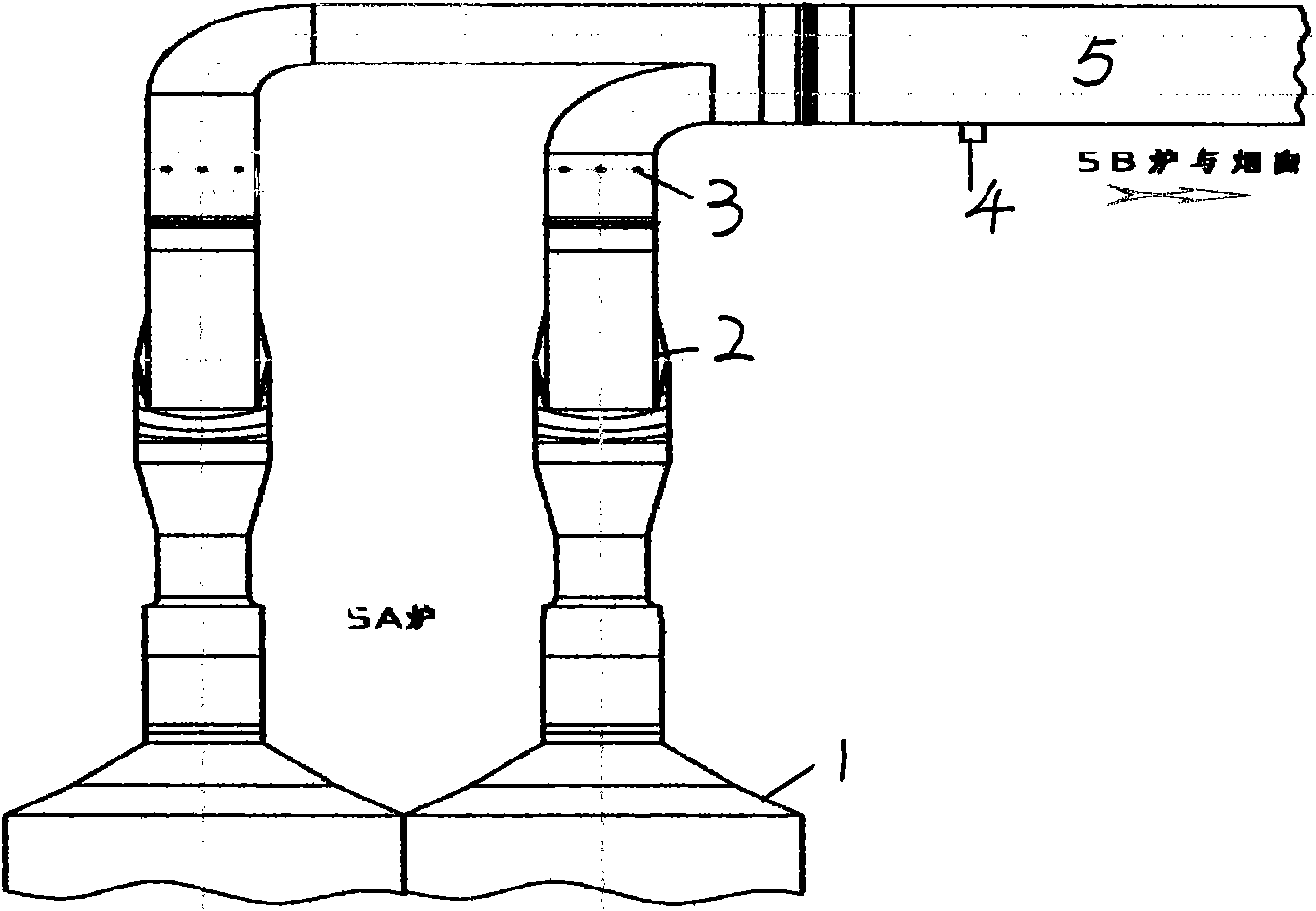

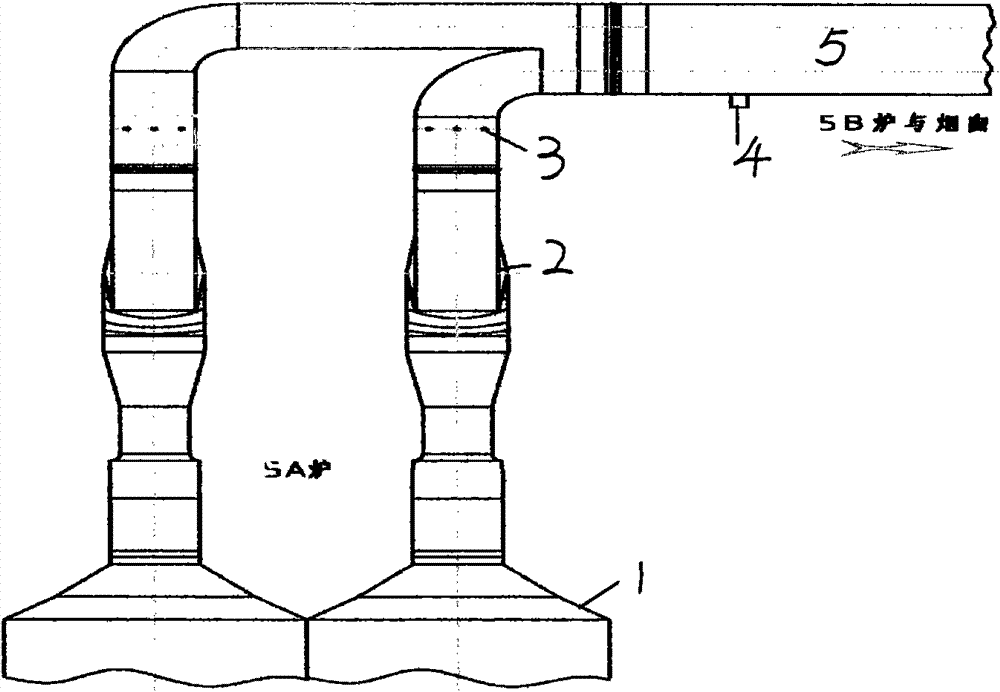

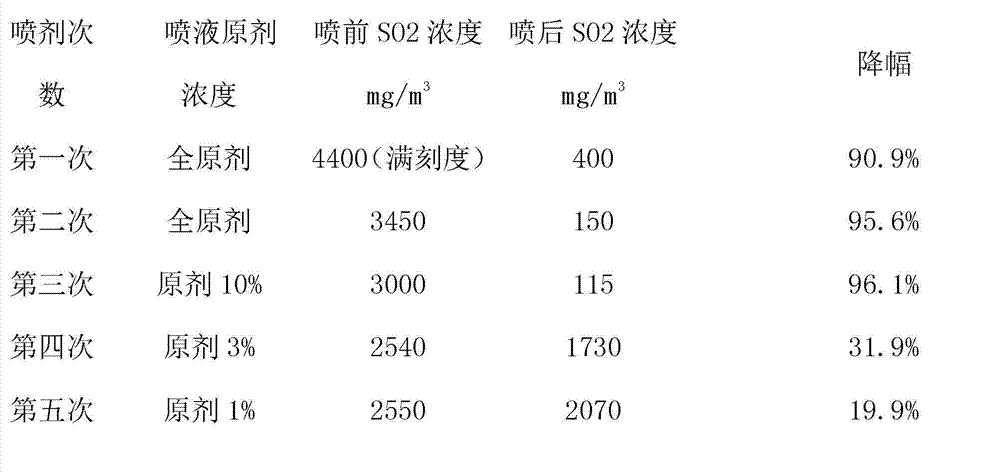

Method for removing sulfur dioxide in flue by using desulfurization liquor

InactiveCN101879402ALow input costSimple preparation processDispersed particle separationAtmospheric airPetroleum

The invention relates to a method for removing sulfur dioxide in a flue by using desulfurization liquor. In the method, in a horizontal flue at an outlet of a boiler flue gas tail gas draught fan, the desulfurization liquor is sprayed in a direction facing gas flows to perform a reaction for removing the sulfur dioxide, and a clean flue gas after removing the sulfur dioxide is discharged into theatmosphere, wherein the desulfurization liquor comprises the following components in percentage by weight: 50 to 80 percent of a quaternary ammonium base organic substance and 20 to 50 percent of organic solvent. The method can be used in a thermal power plant and various combustion boilers using oil and coal as fuels to remove the sulfur dioxide in the flue gas, reduce over 90 percent of emission pollution, and greatly improve the working efficiency. The method has a significant substantial effect. Besides, the method has a simple preparation process of the desulfurization liquor, a low input cost and high practicability.

Owner:SHANGHAI GUBAO IND

Automatic loading and drying system for compound fertilizer granules

InactiveCN103727764AIngenious designReasonable designDrying solid materialsDrying machinesProgrammable logic controllerEngineering

The invention discloses an automatic loading and drying system for compound fertilizer granules. The automatic loading and drying system comprises a feeding mechanism and a drying device and is characterized in that a feeding device comprises a prepared rail and a weighing rail which is connected with the prepared rail; a discharging device is arranged at the top of the weighing rail and comprises a material bin, a discharging plate and a gate which is connected with a weighing sensor of the weighing rail; a lifting device is arranged at the bottom of the material bin; a transfer rail is connected to the rear of the weighing rail and can transfer the materials into the drying device; operation of parts of the feeding device can be controlled through a PLC (programmable logic controller) system. The automatic loading and drying system is ingenious and reasonable in design and high in systematicness; with the compound fertilizer granule loading and drying functions, the system is high in automation level and can be used in combination of existing granule making equipment.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

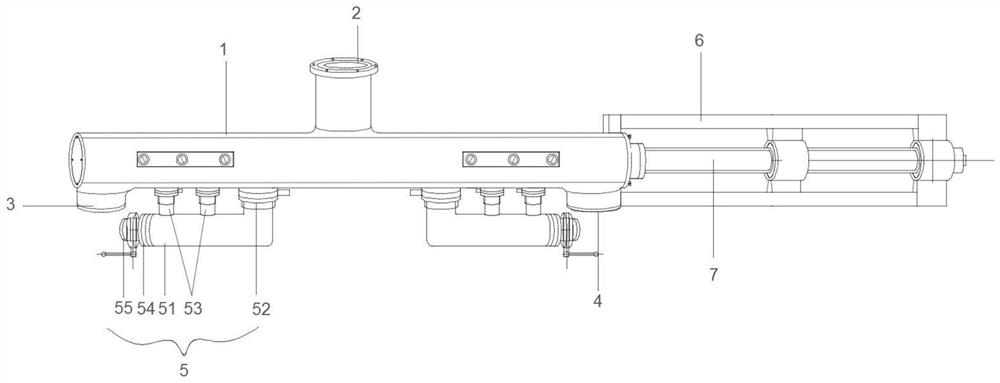

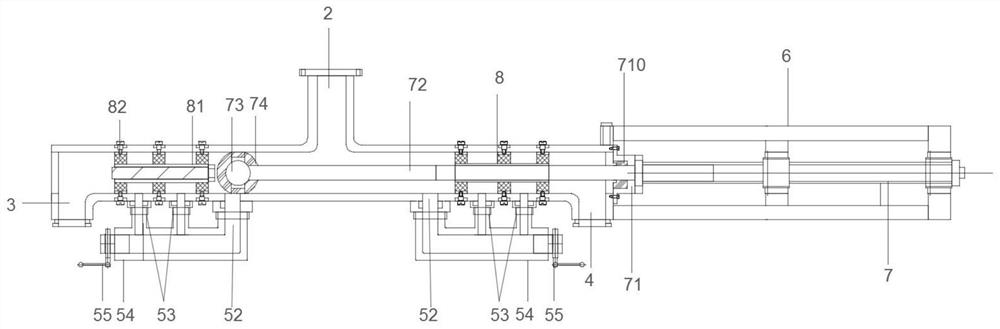

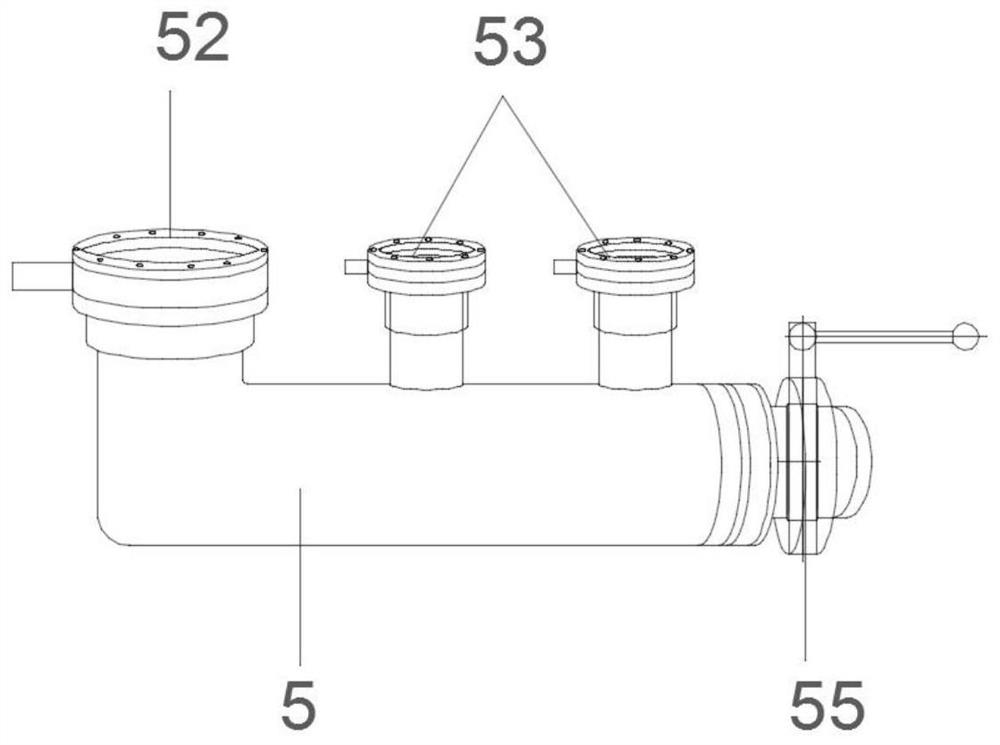

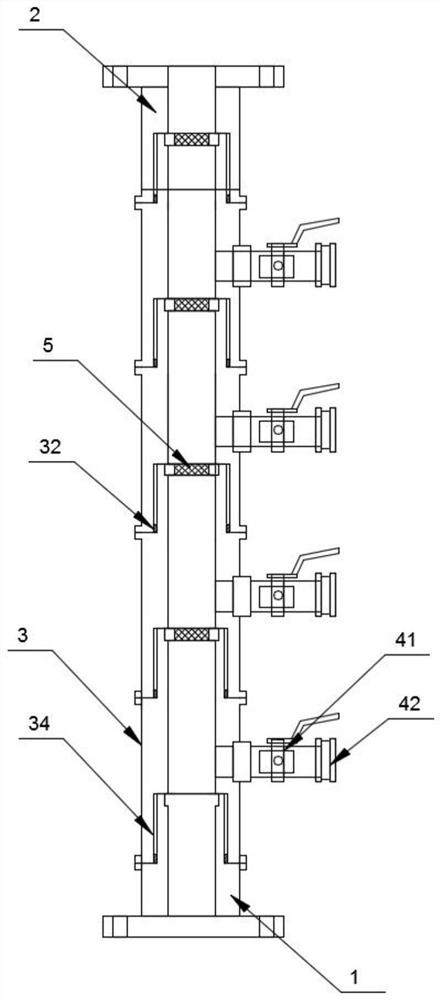

Multi-stage water treatment device

The invention relates to the technical field of water treatment equipment, and concretely relates to a multi-stage water treatment device. The device comprises a three-way pipe body, a water inlet formed in the upper side of the three-way pipe body, a first water outlet and a second water outlet, and the first water outlet and the second water outlet are formed in the lower sides of the two ends of the three-way pipe body respectively and communicate with the water inlet. Two L-shaped sewage storage pipes are detachably installed on the lower side of the three-way pipe body, two multi-stage filtering pieces are arranged between the first water outlet and the second water outlet of the three-way pipe body and used for conducting multi-stage filtering on a water source, the filtering effect is good, the two L-shaped sewage storage pipes are connected to the lower side of the three-way pipe body through flanges, the two L-shaped sewage storage pipes are arranged between the two multi-stage filtering pieces respectively, and are respectively used for precipitating impurities and sewage filtered by the multiple stages of filtering parts, the water source can be effectively shunted, the two multi-stage filtering parts are arranged between the first water outlet and the second water outlet and used for multi-stage filtering of the water source, the filtering effect is good, and the impurities and the sewage can be directly precipitated in the L-shaped sewage storage pipes and discharged conveniently.

Owner:陈清达

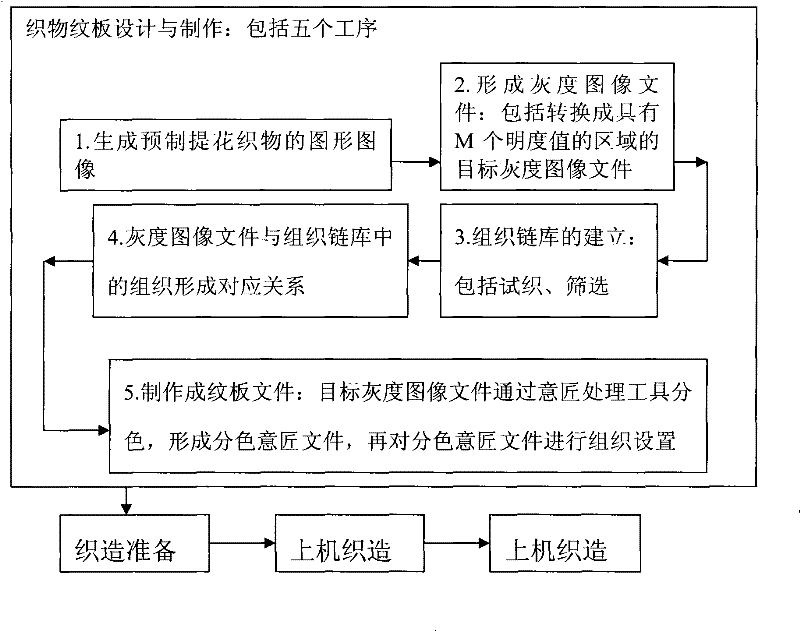

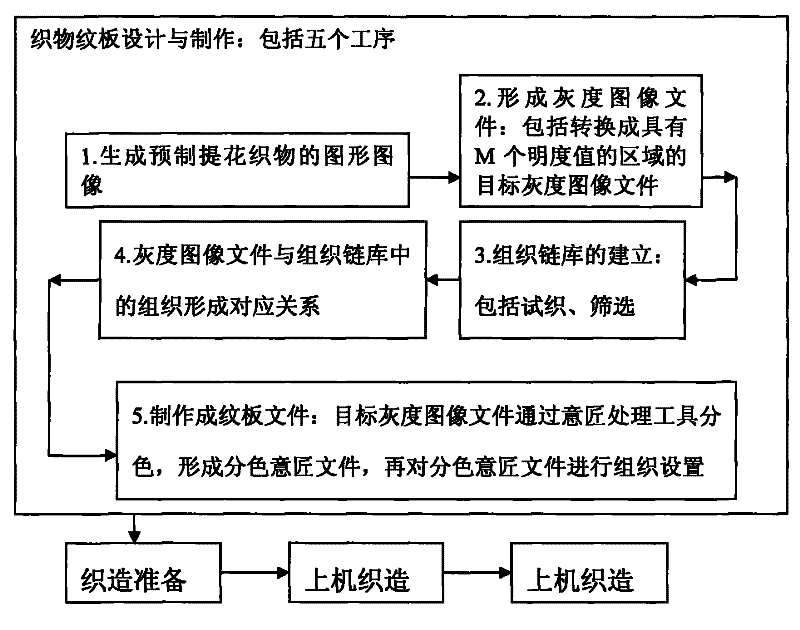

Preparation process of monochrome graded display jacquard fabric

InactiveCN101445988BAccurate configurationRich layersCard-punching apparatusSwivel-woven fabricsYarnDigital image

The invention relates to a preparation process of monochrome graded display jacquard fabric. The preparation process comprises the following steps: (1) designing and manufacturing a fabric card; (2) preparing for weaving; (3) looming and weaving; and (4) manufacturing a finished product. The preparation process is characterized in that the designing and manufacturing the fabric card is as follows: (1) generating a digital image of prefabricated jacquard fabric; (2) forming the digital image into a gray scale image file; (3) creating a tissue link library with different lightness values; (4) causing the gray scale image file and tissues in the tissue link library to form a corresponding relation; and (5) manufacturing a fabric card file. The significant substantial effects of the preparation process are as follows: 1. processing warp and weft with uniform dyeing and applying the creation of a tissue model, thus ensuring precision configuration, abundant hierarchy and exquisite variation of the fabric texture; 2. having simple production process and little limitation and reducing the cost of raw materials; and 3. being capable of dyeing after weaving gray warp and weft, thus processis simple and dye is saved.

Owner:ZHEJIANG SCI-TECH UNIV

Method for removing sulfur dioxide in flue by using desulfurization liquor

InactiveCN101879402BLow input costSimple preparation processDispersed particle separationLow inputPetroleum

Owner:SHANGHAI GUBAO IND

Water circulation filtering device

InactiveCN112957821AGuarantee water qualitySimple structureTreatment involving filtrationMultistage water/sewage treatmentWater sourceDouble filtration

The invention relates to the technical field of water treatment devices, in particular to a water circulation filtering device. Two oppositely-arranged U-shaped filtering pipes can effectively divide a water source entering a water inlet pipe of a three-way machine, so that the water source can be divided into two paths to be filtered by filter screens on the inner sides of the U-shaped filtering pipes, and the filtering efficiency of the filter screens on the water source is improved. Two filter screens are arranged in each U-shaped filtering pipe for double filtration, filtered impurities are respectively precipitated in L-shaped sewage storage pipes on the lower sides of the U-shaped filtering pipes, and the impurities enter a multi-way connecting piece from the U-shaped filtering pipes for collection. Due to the fact that the bottom of the multi-way connecting piece is connected with a filter, the collected impurity sewage can be further filtered, filtered impurities are discharged out of the filter, the filtered water directly enters the water inlet pipe of the three-way machine again through a water return pipe under the action of a water pump to be utilized and sequentially and circularly filtered, the water source filtering effect can be greatly improved, and the water quality is guaranteed.

Owner:郭冬青

Continuous loose fiber cleaning machine

InactiveCN101954357BUniform temperatureHighlight the substantive effectCleaning using liquidsFiberEngineering

The invention relates to a continuous loose fiber cleaning machine comprising a plurality of groups of cleaning units, cleaning tanks arranged in each group of cleaning units and conveying mechanisms matched with the cleaning tanks, wherein each conveying mechanism comprises a dual mesh belt cleaning and conveying mechanism which comprises a closed annular mesh belt A, a closed annular mesh belt B and a driving assembly which is respectively in driving fit with each cleaning mesh belt; two annular cleaning mesh belts positioned in the cleaning tanks are in clearance overlapping fit; the two annular cleaning mesh belts respectively form a duck bill input port and a duck bill output port at the inlet port and the outlet end of the cleaning tank; and two annular cleaning mesh belts positioned outside the cleaning tank are respectively matched with the driving assembly to form annular driving. The invention has the predominant substantial effect: the tiled loose fibers are clamped by the dual mesh belt cleaning and conveying mechanism, enter the cleaning tanks and are easy to clean; in addition, the loose fiber sequentially enters each cleaning tank and can be cleaned more thoroughly.

Owner:新昌县艺力机械有限公司

Continuous Loose Fiber Dyeing Machine

ActiveCN101949086BReduce consumptionHighlight the substantive effectTextile treatment containersTextile treatment carriersRing dyeingPulp and paper industry

The invention relates to a continuous loose fiber dyeing machine. The continuous loose fiber dyeing machine comprises a dye vat; a mechanism which is fitted with the dye vat and used for conveying loose fibers is a double mesh belt dyeing conveying mechanism, and the double mesh belt dyeing conveying mechanism comprises two closed mesh belts (namely, a ring mesh belt A and a ring mesh belt B) and transmission components which are respectively in transmission fit with each ring mesh belt; two ring dyeing mesh belts in the dye vat are in clearance stacking fit with each other, the two ring dyeing mesh belts respectively fitted with the inlet end and the outlet end of the dye vat respectively form a duckbilled input port and a duckbilled output port, and the two ring dyeing mesh belts arranged outside the dye vat are respectively fitted with the respective transmission components so as to form a circular transmission. The invention has the prominent and substantive effects as follows: because the loose fibers are clamped and then sent to the dye vat for dyeing and the loose fiber is thin, the loose fiber is easy to be dyed completely; and with the help of shower pipes, the dye permeability of the loose fibers is improved, and little dyes are taken away, therefore, the dye consumption is saved.

Owner:新昌县艺力机械有限公司 +1

Compound fertilizer granulation assembly system

ActiveCN103694063AAchieve granulationAchieve dryingGranulation in rotating drumsFertiliser formsSprayerEconomic benefits

The invention discloses a compound fertilizer granulation assembly system which comprises a granulator and a drier connected with the granulator. The system is characterized in that the granulator comprises a rotating drum, wherein the top of the rotating drum is provided with a feed port, the middle of the rotating drum is provided with a worm transmission part, the position with the same center of circle as the worm transmission part in the rotating drum is provided with a rotary sprayer, and the rotating drum and the rotary sprayer are driven to rotate by the same power source. The system has the advantages of ingenious and reasonable design and high systematicness; by arranging the multistage equipment, the system can effectively implement the functions of granulating, drying screening and assembling the compound fertilizer, has high degree of automation and superior performance; and compared with the existing split equipment, the efficiency is enhanced by more than 40%, and the economic benefit is enhanced by more than 30%.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

Compound fertilizer granulation continuous feeding assembly system

ActiveCN103694062BAchieve granulationAchieve dryingFertiliser formsFertilizer mixturesCooking & bakingEconomic benefits

The invention discloses a continuous feeding assembly system for pelletizing a compound fertilizer. The continuous feeding assembly system comprises a pelletizing device, and a baking device connected with the pelletizing device. The continuous feeding assembly system is characterized in that the pelletizing device comprises a drum, wherein two ends of the drum are hollow; a feeding hole pipeline is arranged at the end part of the drum; a worm transmission component is arranged at the middle part of the drum; a rotary shower nozzle is also arranged concentrically with the worm transmission component inside the drum; the drum and the rotary shower nozzle are driven to rotate through a same power source; the rotary shower nozzle is fixed outside the drum through a fixing element. The continuous feeding assembly system is clever and reasonable in design, strong in systematicness, high in automatic degree, and excellent in performance, can achieve a continuous feeding function, and can effectively achieve the function of pelletizing, baking, screening and assembling the compound fertilizer by providing multi-sectional equipment. Compared with the existing split-type equipment, the efficiency is improved by over 40%, and the economic benefits are improved by over 30%.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

Anti-overpressure compound fertilizer granulation assembly system

ActiveCN103694061BAchieve granulationIngenious designGranulation in rotating drumsFertiliser formsEconomic benefitsEngineering

The invention discloses an anti-overpressure compound fertilizer granulation assembly system which comprises a granulator and a drier connected with the granulator. The system is characterized in that the granulator comprises a rotating drum, wherein the top of the rotating drum is provided with a feed port, the middle of the rotating drum is provided with a worm transmission part, the position with the same center of circle as the worm transmission part in the rotating drum is provided with a rotary sprayer, and the rotating drum and the rotary sprayer are driven to rotate by the same power source. The system has the advantages of ingenious and reasonable design and high systematicness; by arranging the multistage equipment, the system can effectively implement the functions of granulating, drying screening and assembling the compound fertilizer, has high degree of automation and superior performance; and compared with the existing split equipment, the efficiency is enhanced by more than 40%, and the economic benefit is enhanced by more than 30%.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

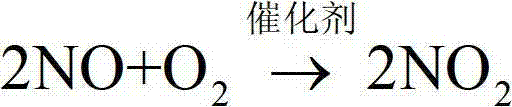

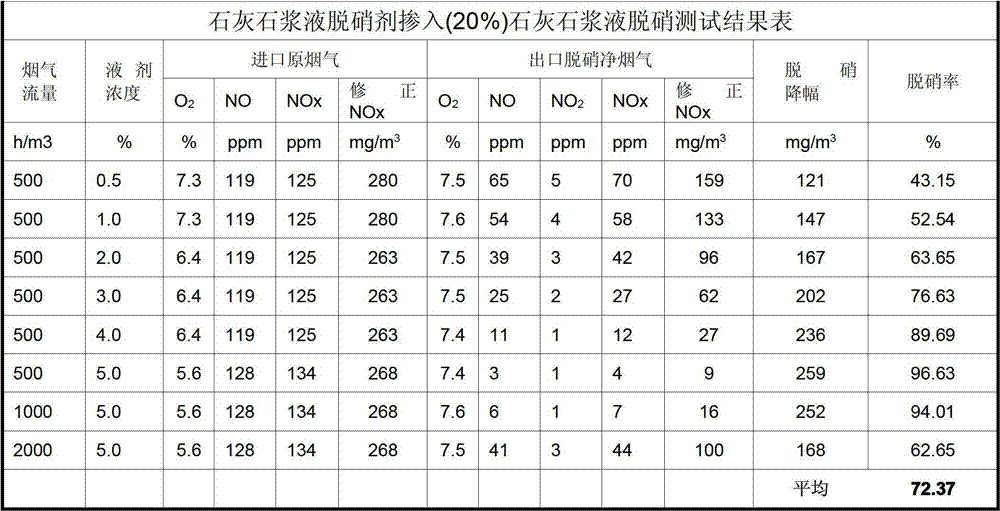

Composition and method for removing nitrogen oxides in desulfurizing tower

ActiveCN102728215BEfficient removalTo achieve the purpose of removing NOxDispersed particle separationAir quality improvementSlurrySolvent

The invention relates to a composite denitrfying agent and a method for removing nitrogen oxides from purified flue gas, and in particular relates to a method for forming a mixture with limestone slurry in a desulfurizing tower, desulfurizing the limestone slurry and removing the nitrogen oxides in the composition. The composition is formed by desulfurizing and denitrifying 0.5 to 5 weight parts of denitrfying agent and 100 weight parts of aqueous solution of limestone slurry in the desulfurizing tower, wherein the denitrfying agent consists of a catalyst which accounts for 1.7 to 2.3 weight percent of the denitrfying agent, 10 to 20 percent of oxidant and 78.3 to 87.7 percent of ion solvent; and the denitrfying agent has the pH value of 6 to 8. The composition is injected into the desulfurizing tower through a circulating water injection port or a process water injection port and is in countercurrent contact with the flue gas in the desulfurizing tower for removing the nitrogen oxides. The method can be used for thermal power plants and various combustion boilers which take petroleum and oil as fuel and comprise the desulfurizing tower device, and is used for removing the nitrogen oxides in the flue gas, and 90 percent of emission pollution is reduced. The method has obvious substantive effects.

Owner:SHANGHAI YUHUAN CHEM TECH

Detachable and assembled arc-shaped precise positioning equipment

ActiveCN105916463BPrevent rotationIncrease operating spaceInstruments for stereotaxic surgeryLong axisEngineering

The invention relates to detachable-mountable arc-shaped precise positioning equipment, which includes a supporting unit, a three-dimensional regulating unit connected to the supporting unit, and a guidance positioning unit. The guidance positioning unit includes an arc-shaped rail, a guide rod, a holder, and positioning meters. A second sliding block is connected to the three-dimensional regulating unit; the arc-shaped rail is arranged and slides on the second sliding block, and can be subjected to in-situ rotation around a vertical axis at any angle; the three-dimensional regulating unit drives the arc-shaped rail to move in three dimensions of up-down, left-right, and front-back dimensions; the guide rod can slide along the arc-shaped rail and moves long a long axial direction of the guide rod; and the holder is arranged on the guide rod for fixing a surgical instrument. There are two positioning meters, and rays sent by the two positioning meters, along with a long axis of the holder, are parallel to or coincide with a radial line of the arc-shaped rail. The three lines are located on a same plane, which is parallel to or coincide with the plane where the arc-shaped rail is located. The three lines intersect at one point.

Owner:SHANGHAI TENTH PEOPLES HOSPITAL

Compound fertilizer granule charging and drying system

ActiveCN103727765BIngenious designReasonable designDrying solid materialsDrying machinesProgrammable logic controllerAgricultural engineering

The invention discloses a loading and drying system for compound fertilizer granules. The loading and drying system comprises a feeding mechanism and a drying device and is characterized in that a feeding device comprises a prepared rail and a weighing rail which is connected with the prepared rail; a discharging device is arranged at the top of the weighing rail and comprises a material bin, a discharging plate and a gate which is connected with a weighing sensor of the weighing rail; a transfer rail is connected to the rear of the weighing rail and can transfer the materials into the drying device; operation of parts of the feeding device is controlled through a PLC (programmable logic controller) system. The loading and drying system is ingenious and reasonable in design and high in systematicness; with the compound fertilizer granule loading and drying functions, the system is high in automation level and can be used in combination of existing granule making equipment.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

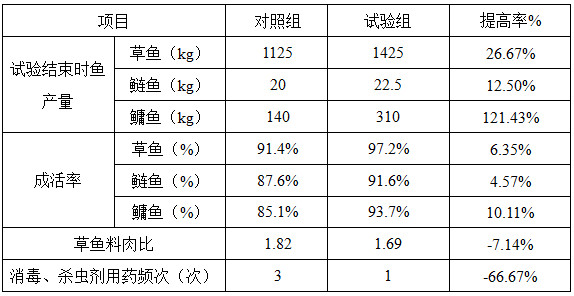

A kind of water transfer method for aquatic healthy ecological cultivation

ActiveCN109804962BHighlight the substantive effectSolve the use problemPisciculture and aquariaMultistage water/sewage treatmentAquatic animalImmunity

Owner:北京新农匠生态科技有限公司

Compound fertilizer granule automatic loading and drying system

InactiveCN103727764BIngenious designReasonable designDrying solid materialsDrying machinesEngineeringLoad cell

The invention discloses an automatic loading and drying system for compound fertilizer granules, which includes a feeding mechanism and a drying device, and is characterized in that: the feeding device includes a preparation track and a weighing track connected thereto, and the top of the weighing track is set There is an unloading device, the unloading device includes a silo, an unloading plate, and a gate, the gate is connected to the weighing sensor on the weighing track, a lifting device is provided at the bottom of the silo, and the weighing The rear part of the track is connected to the conveying track, which can transport the material to the drying device, and the operation of each component in the feeding device is controlled by the PLC system. The invention is ingenious in design, reasonable and strong in systematization. By setting two functions of loading compound fertilizer and drying compound fertilizer, the invention has a high degree of automation and can be used in combination with existing granulation equipment.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

Compound fertilizer particle screening charging drying system

ActiveCN103727766BImprove pass rateIngenious designDrying solid materialsDrying machinesProgrammable logic controllerAgricultural engineering

The invention discloses a screening, loading and drying system for compound fertilizer granules. The screening, loading and drying system comprises a feeding mechanism and a drying device and is characterized in that a feeding device comprises a prepared rail and a weighing rail which is connected with the prepared rail; a discharging device is arranged at the top of the weighing rail and comprises a material bin, a discharging plate and a gate which is connected with a weighing sensor on the weighing rail; a transfer rail is connected to the rear of the weighing rail and can transfer the materials into the drying device; operation of parts of the feeding device is controlled through a PLC (programmable logic controller) system. The screening, loading and drying system is ingenious and reasonable in design and high in systematicness; with the compound fertilizer granule loading and drying functions, the system is high in automation level and can be used in combination of existing granule making equipment; in addition, by the arrangement of the material bin with a screen, acceptability of the compound fertilizer granules can be improved.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

Compound fertilizer granulation assembly system

ActiveCN103694063BAchieve granulationAchieve dryingGranulation in rotating drumsFertiliser formsSprayerEconomic benefits

The invention discloses a compound fertilizer granulation assembly system which comprises a granulator and a drier connected with the granulator. The system is characterized in that the granulator comprises a rotating drum, wherein the top of the rotating drum is provided with a feed port, the middle of the rotating drum is provided with a worm transmission part, the position with the same center of circle as the worm transmission part in the rotating drum is provided with a rotary sprayer, and the rotating drum and the rotary sprayer are driven to rotate by the same power source. The system has the advantages of ingenious and reasonable design and high systematicness; by arranging the multistage equipment, the system can effectively implement the functions of granulating, drying screening and assembling the compound fertilizer, has high degree of automation and superior performance; and compared with the existing split equipment, the efficiency is enhanced by more than 40%, and the economic benefit is enhanced by more than 30%.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

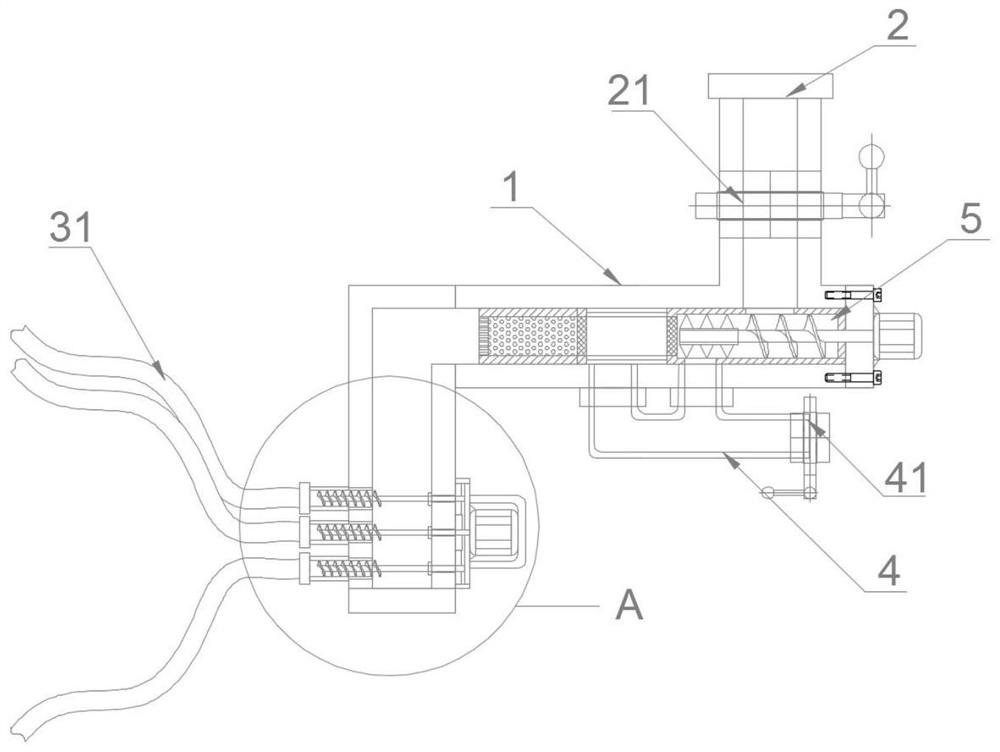

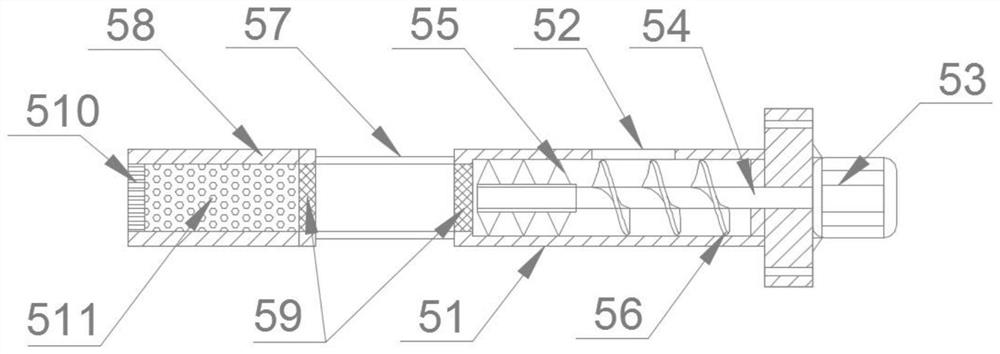

Water treatment valve pipe

PendingCN112870841AEasy to disassemble and replaceEasy maintenanceSpecific water treatment objectivesMultistage water/sewage treatmentElectric machineryValved tube

The invention relates to the technical field of water treatment equipment, in particular to a water treatment valve pipe which comprises an N-shaped communicating pipe, a water inlet formed in one end of the N-shaped communicating pipe and a plurality of water outlet connecting pipes arranged at the other end of the N-shaped communicating pipe. A blow-off pipe is detachably connected to the lower side of the N-shaped communicating pipe, and a filtering treatment device is arranged on the inner side of the N-shaped communicating pipe. The blow-off pipe is arranged on the lower side of the filtering treatment device. An extrusion device is arranged at the position of the water outlet connecting pipe at the tail end of the N-shaped communicating pipe. The filtering treatment device comprises an insertion pipe, a water passing opening, a dispersion driving motor, a rotating shaft, a smashing knife roll, a first spiral blade and a connecting rod. One end of the insertion pipe is inserted into the inner side of the N-shaped communicating pipe, and the other end of the insertion pipeis locked with one side of N-shaped communicating pipe through screws. According to the water treatment valve pipe, tap water can be effectively purified, so that the water quality is further improved, the water treatment valve pipe is convenient to disassemble, assemble and maintain in the later period, the water treatment valve pipe can be precipitated on the blow-down valve to discharge sewage outwards, and the water treatment valve pipe is simple and convenient to use.

Owner:彭昌昌

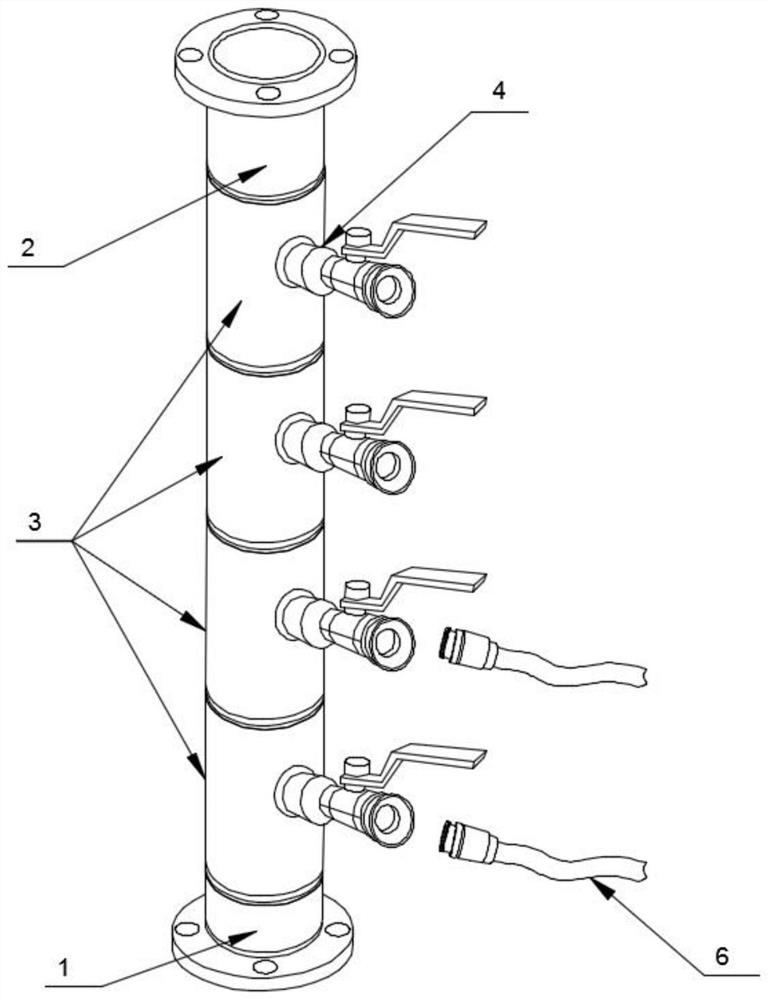

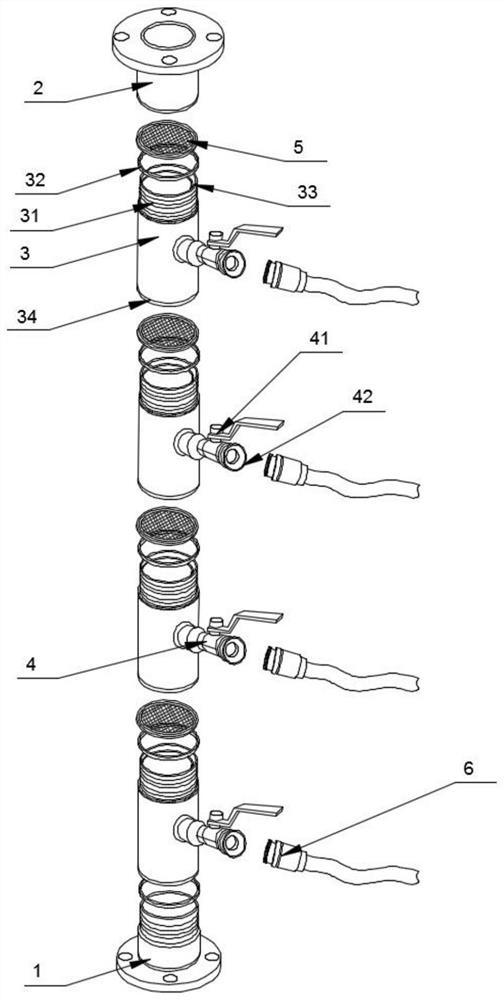

Water treatment pipeline convenient to disassemble and use

InactiveCN112973250AEasy maintenanceEasy to replaceCouplingsScrew threaded jointsWater sourceEngineering

The invention relates to the technical field of water treatment devices, in particular to a water treatment pipeline convenient to disassemble and use. The water treatment pipeline comprises a water inlet pipe and a water outlet pipe, one end of the water inlet pipe and one end of the water outlet pipe can be in detachable flange connection with an external water pipe, and a plurality of connecting pipes are detachably connected between the water inlet pipe and the water outlet pipe. The opposite ends of the connecting pipes are detachably connected, the water inlet pipe and the water outlet pipe are both in flange connection with a water conveying pipe so that detaching and replacing are facilitated, a plurality of through connecting pipes are detachably connected between the water inlet pipe and the water outlet pipe, and the connecting pipes are detachably connected end to end through threads, and thus the connecting pipes can be conveneintly detached and maintained, the filtering net pieces are arranged between the connecting pipes, a water source can be further filtered in a multi-layer mode when water is conveyed, the water source is effectively purified, and filtered impurities can be discharged outwards through the blow-off pipes on one sides of the connecting pipes.

Owner:张娇蓉

Tube management machine yarn bobbin directional conveying device

ActiveCN106256721BHigh speedRealize the function of fast combing and orientationConveyorsConveyor partsYarnBobbin

The invention belongs to the technical field of textile machines, and discloses a directional bobbin conveying device of a bobbin arranging machine. The directional bobbin conveying device comprises a bobbin bin, a first-stage lifting mechanism, a bobbin straightening conveying mechanism, a second-stage lifting mechanism, a large bobbin removing mechanism and a directional mechanism. Bobbins are lifted in two stages through the first-stage lifting mechanism and the second-stage lifting mechanism, so that the bobbin lifting speed is greatly increased; besides, the bobbins are directionally conveyed at a constant speed, so that the bobbin arranging efficiency is improved. Large bobbins with end yarns wound are accurately removed in the lifting process, and a beating mechanism is adopted in the large bobbin removing process, so that compared with an air cylinder structure, the handling speed is greatly increased, and the structure is simple. The physical principle that the rolling speed of the large ends of the bobbins is larger than that of the small ends of the bobbins in the directional bobbin conveying process is utilized, and an optimized angle is adopted to make the bobbins roll at the maximum angle without sliding relative to a directional roller path, so that the bobbins are rapidly pulled to a next process when the large ends of the bobbins roll onto conveying belts, and the function of rapidly and directionally arranging bobbins is achieved.

Owner:ZHEJIANG ZILI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com