High-speed arrangement device for ring bobbins

A finishing device and spinning bobbin technology, applied in the field of textile machinery, can solve problems such as low accuracy, slow response speed, and high production cost, and achieve the effects of improving efficiency, saving time, and solving slow orientation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

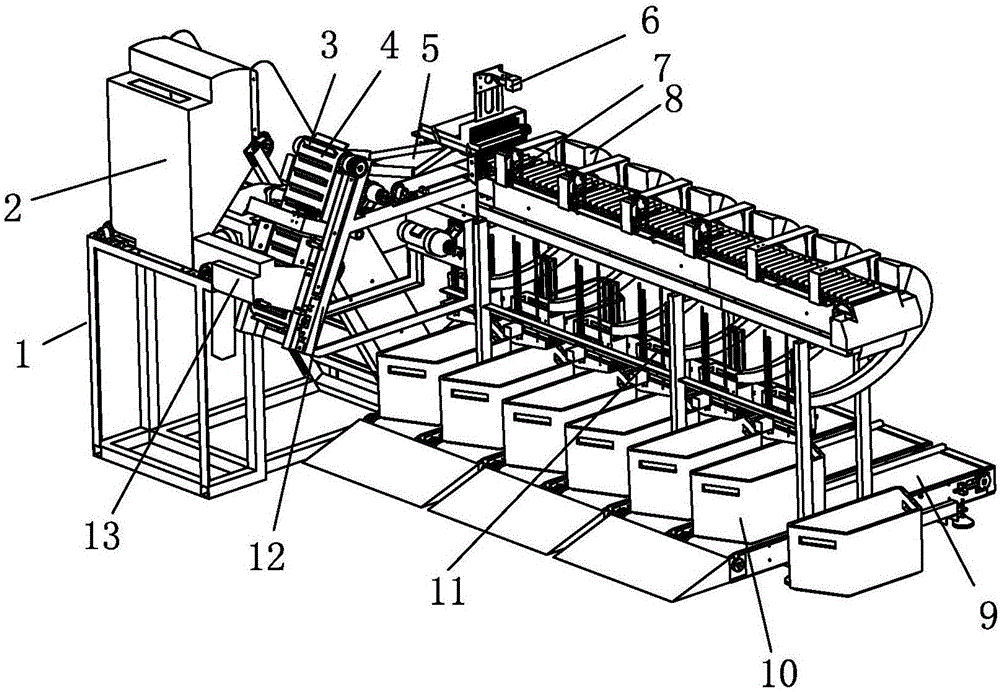

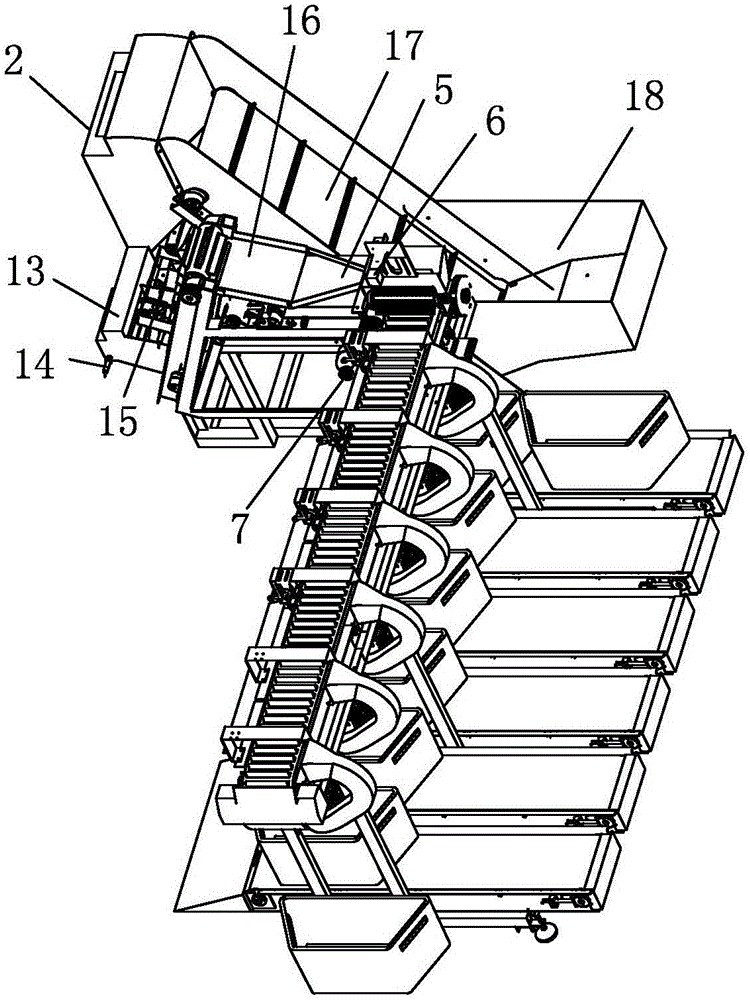

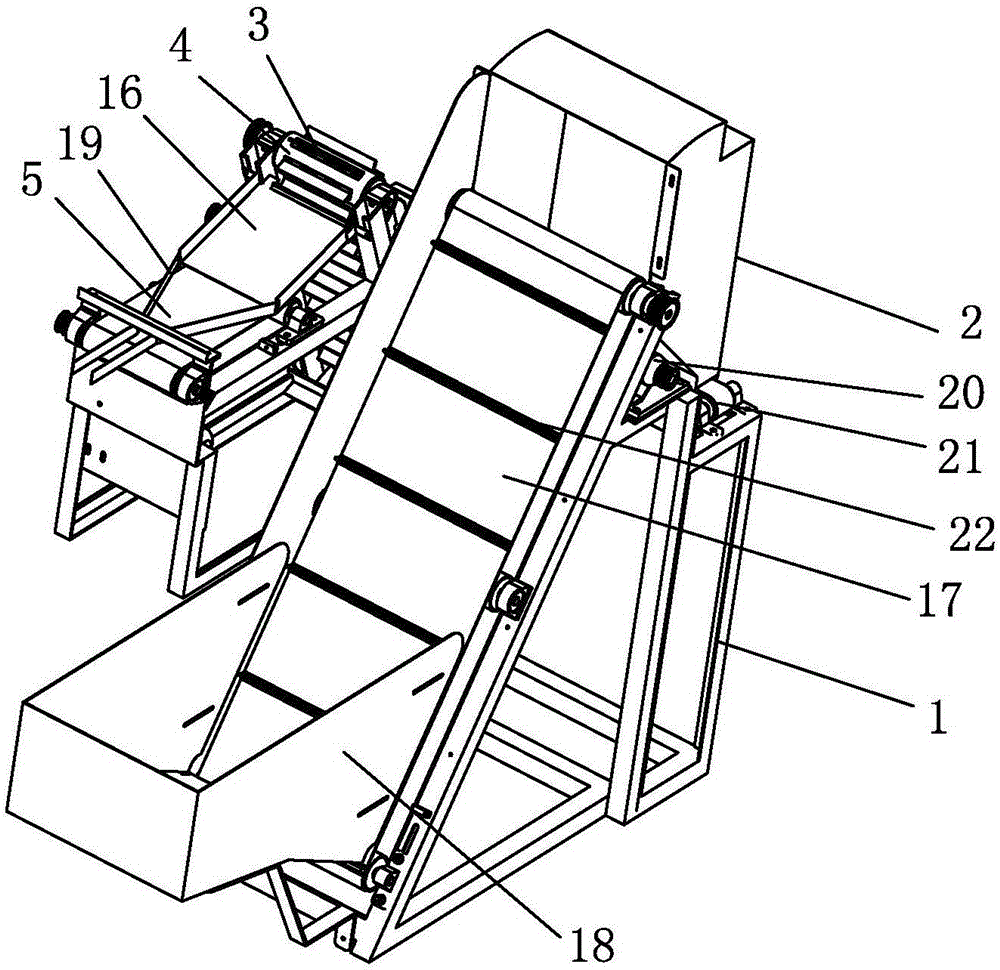

[0022] like Figure 1~Figure 4 As shown, the present invention includes a bobbin bin 18, a first lifting mechanism, a yarn management straight delivery mechanism, a second lifting mechanism, a large bobbin rejecting mechanism, an orientation mechanism, a color separation system and a control system, and the bobbin bin 18 Fixedly installed by a frame 1, the first lifting mechanism includes a first lifting channel 17 and a first lifting drive mechanism 20 that drives the first lifting channel 17 to move up, and the first lifting channel 17 is installed obliquely on the On the frame 1, the lower end of the first lifting channel 17 stretches into the bobbin bin 18, the rear side of the upper end of the first lifting channel 17 is used as the outlet end, and the bottom of the first lifting channel 17 is There are horizontally distributed bobbin su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com