Compound fertilizer granule charging and drying system

A technology of drying system and compound fertilizer, applied in drying, dryer, transportation and packaging, etc., can solve the problem of low degree of automation, and achieve the effect of easy popularization and application, high degree of automation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

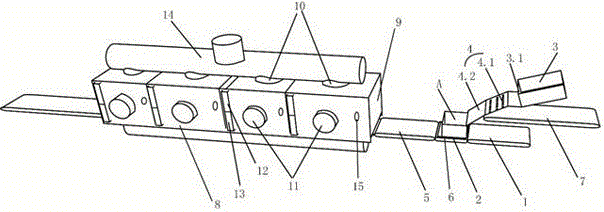

[0023] Such as figure 1 As shown, the compound fertilizer granule loading and drying system includes a feeding device and a drying device. The feeding device includes a preparation track 1 and a weighing track 2 connected to it. The top of the weighing track 2 is provided with a discharge device. The discharge device It includes a silo 3, a discharge plate 4, and a gate, the gate 3.1 is connected to the load cell 6 on the weighing track 2, the rear of the weighing track 2 is connected to the conveying track 5, and the conveying track 5 can transport the material to the oven. dry device. The stripper plate 4 comprises the upper section 4.1 of the stripper plate and the lower section 4.2 of the stripper plate, the upper section 4.1 of the stripper plate has small holes, and the lower part of the upper section 4.1 of the stripper plate is provided with a fine material conveying mechanism 7.

[0024] The drying device includes a drying room 8. One-way doors 9 are provided at both...

Embodiment 2

[0029] In this embodiment, the difference from Embodiment 1 is that the weighing track 2 is also provided with a weight safety limiting device, which can stop the operation of the preparation track 1, the weighing track 2 and the delivery track 5 in time, and when When the gate 3.1 accidentally dumps materials, the weighing track 2 will not run, thereby preventing accidents from happening.

[0030] In addition, in this embodiment, another drying method is provided, that is, when the 4 charging boxes A are respectively filled with compound fertilizer granules, when they enter the corresponding 4 compartments, they are baked at the same time. Temperature detector 12 and humidity detector 13 monitor temperature and humidity. Thereby, the purpose of simultaneous baking of multiple materials can be achieved.

[0031] The rest of the working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com