Composition and method for removing nitrogen oxides in desulfurizing tower

A technology of nitrogen oxides and desulfurization towers, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of large consumption of ammonia and urea, failure to meet the requirements of emission standards, and linear decline in reaction, etc., to achieve The effect of reducing emission pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

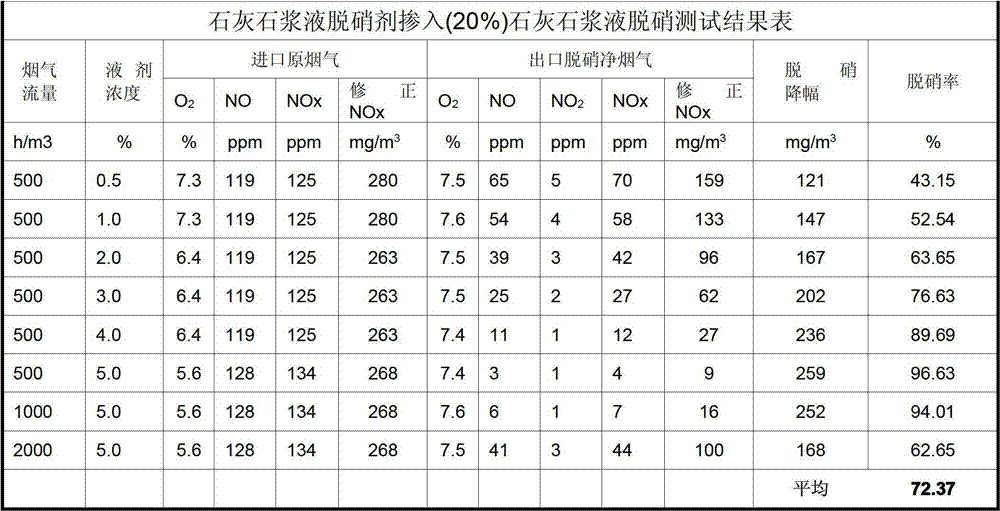

[0025] The composition of the present invention is composed of 0.5-5 parts by weight of the denitration agent and 100 parts by weight of limestone slurry, which form a mixture with the limestone slurry. When the limestone-containing slurry in the desulfurization absorption tower is sprayed to atomize the flue gas, it is dispersed into fine droplets and covers the entire cross-section of the absorption tower. SO in the flue gas when it is in countercurrent contact with the flue gas 2 absorbed. The composition denitrification agent mixed into the limestone slurry also selectively catalyzes the NOx in the flue gas through spray atomization (95% of the NOx in the flue gas is very insoluble in liquid NO, which must first be catalyzed and oxidized to NO 2 Dissolved in the liquid, and then undergoes selective catalytic reduction to generate salt and N 2 ). while NO 2 Dissolved in the liquid agent, only a part is catalyzed by redox, and the other part is NO 2 It will be converted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com