Continuous loose fiber cleaning machine

A cleaning machine and cleaning box technology, applied in the field of cleaning machines, can solve problems such as unfavorable work, large cleaning liquid consumption for cleaning, etc., and achieve the effects of easy cleaning, noise reduction, and uniform steam temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

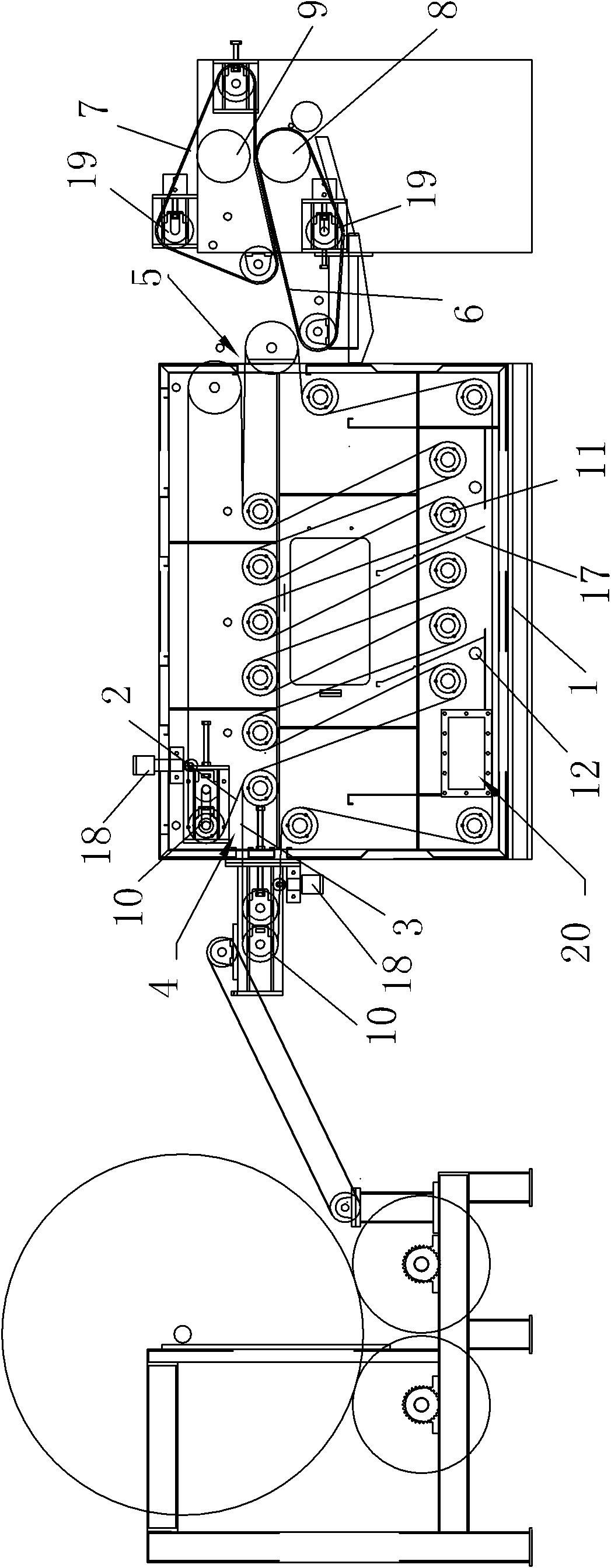

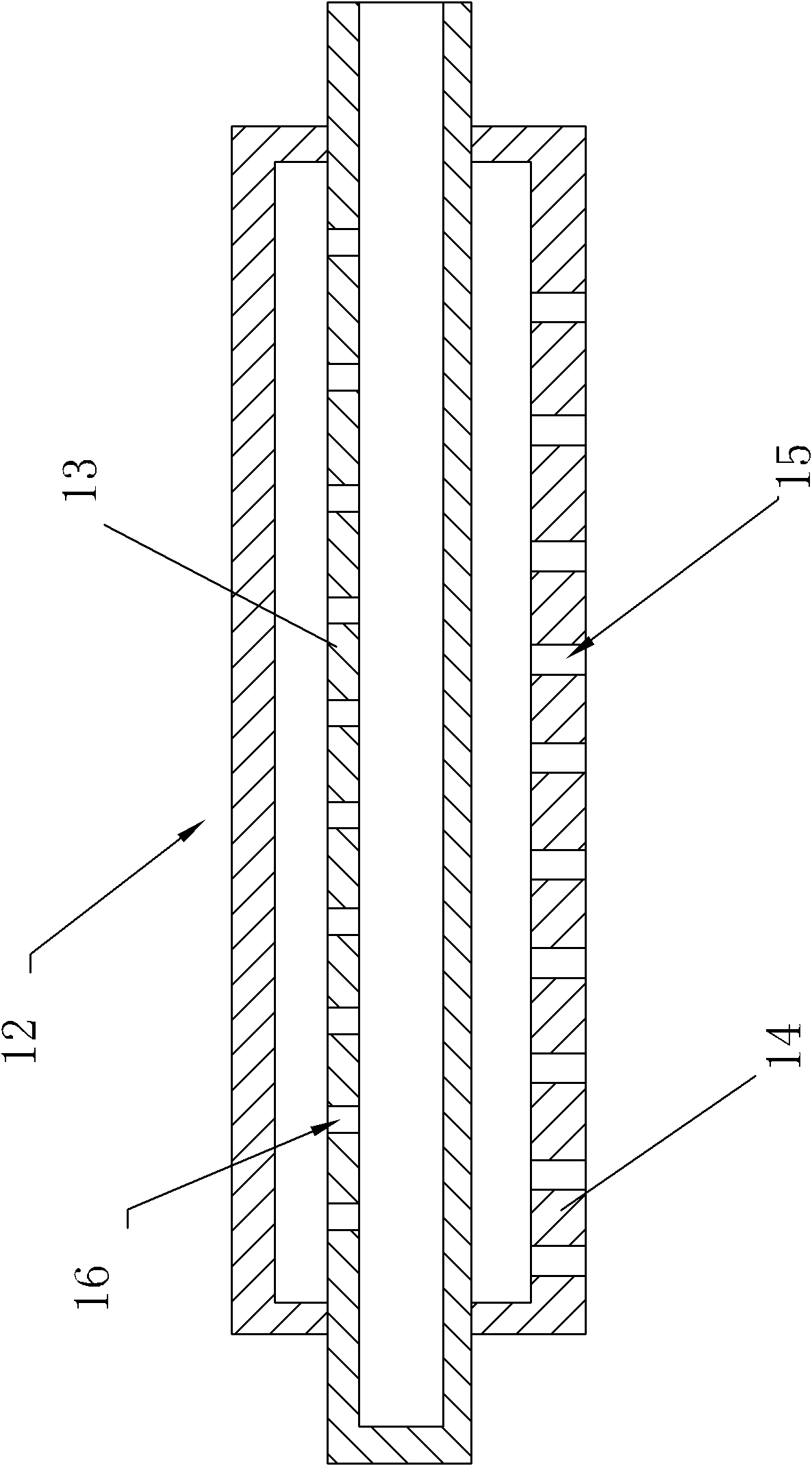

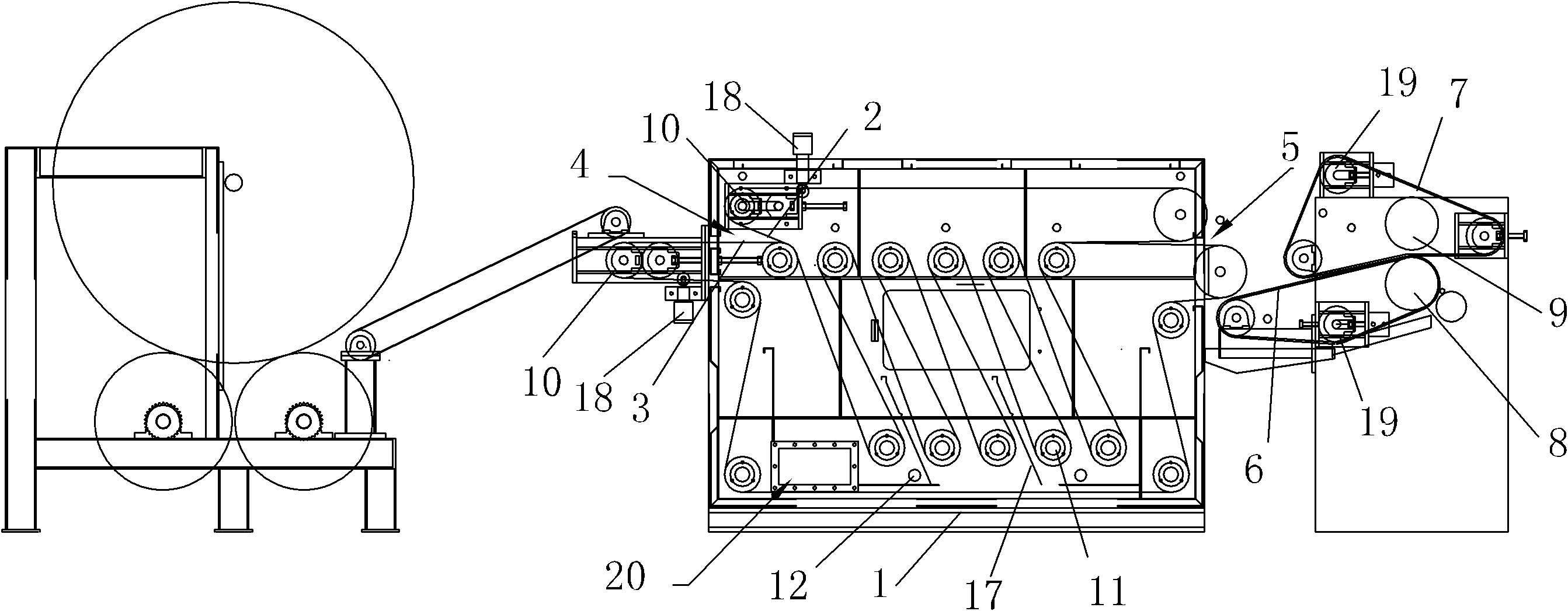

[0015] Embodiment: continuous type loose fiber cleaning machine, such as figure 1 As shown, it is a continuous loose fiber cleaning machine, including multiple groups of cleaning units, and each group of cleaning units includes a cleaning box 1, and a conveying mechanism that matches the cleaning box. The conveying mechanism includes a double mesh belt cleaning conveyor mechanism, and the double mesh belt The cleaning and conveying mechanism includes two closed ring-shaped ring-shaped mesh belts A2 and B3, and the transmission components that are respectively matched with the transmission of each cleaning mesh belt; Two ring-shaped cleaning mesh belts form a duckbill-shaped input port 4 and a duckbill-shaped output port 5 at the inlet and outlet ends of the cleaning box 1 respectively. Matched to form a ring drive. The guide rollers 11 arranged in the cleaning box are arranged in two rows up and down, and the upper row of guide rollers 11 tends to deviate to the left compared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com