Coal-mining machine hydraulic system

A hydraulic system and shearer technology, which is applied to fluid pressure actuating system components, earthwork drilling, slitting machinery, etc., can solve the problems of increased shutdown rate of shearers, frequent failures, and reduced coal output, etc. Achieve the effect of reducing failure rate, reducing maintenance time, and improving operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

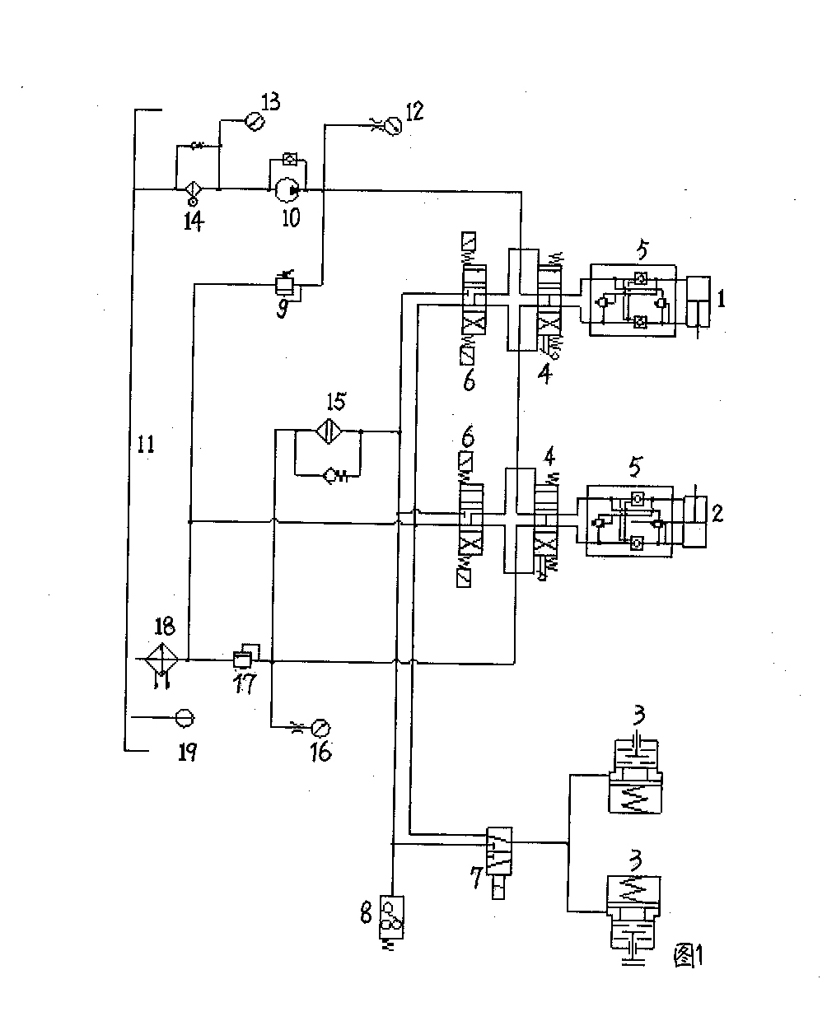

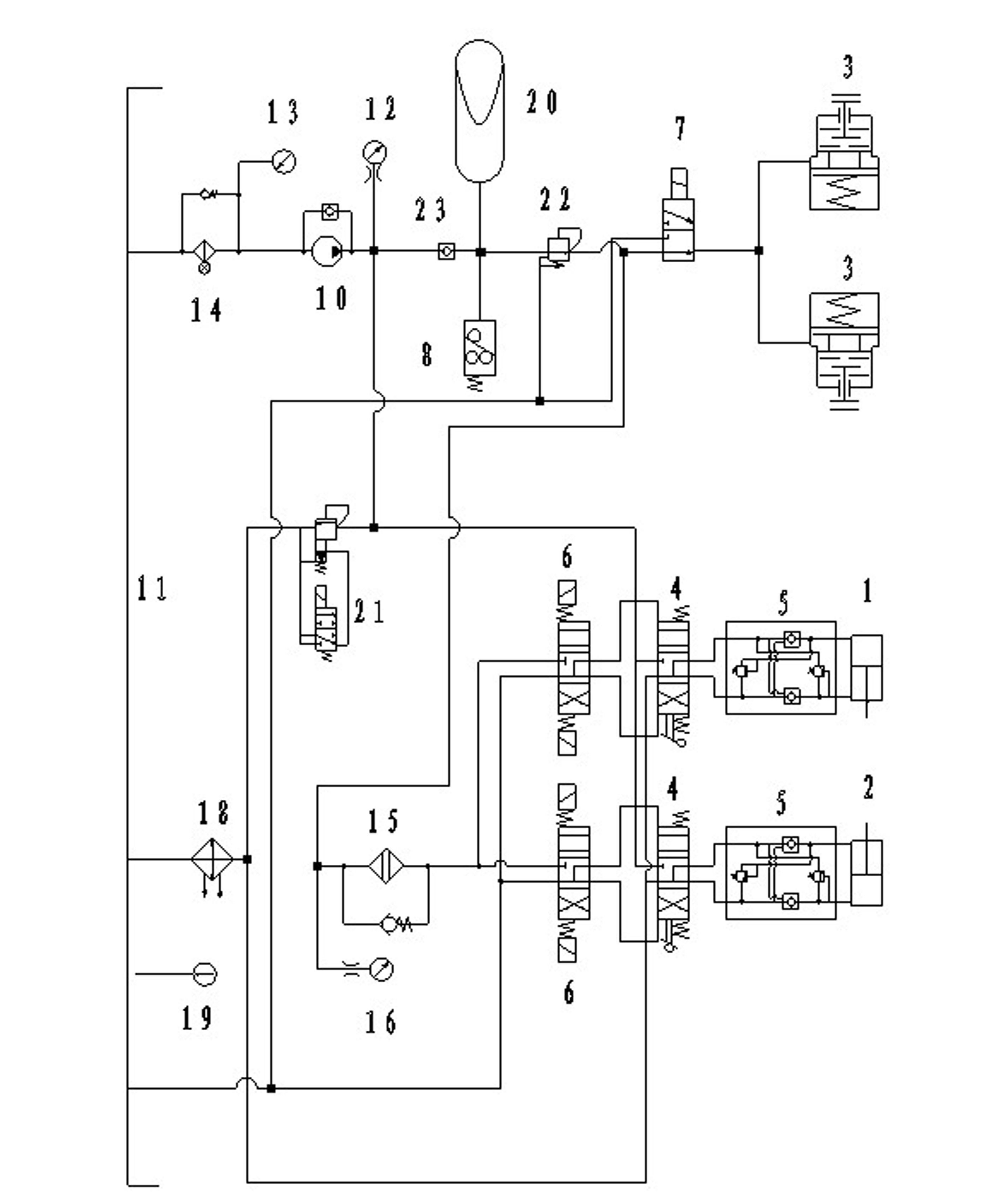

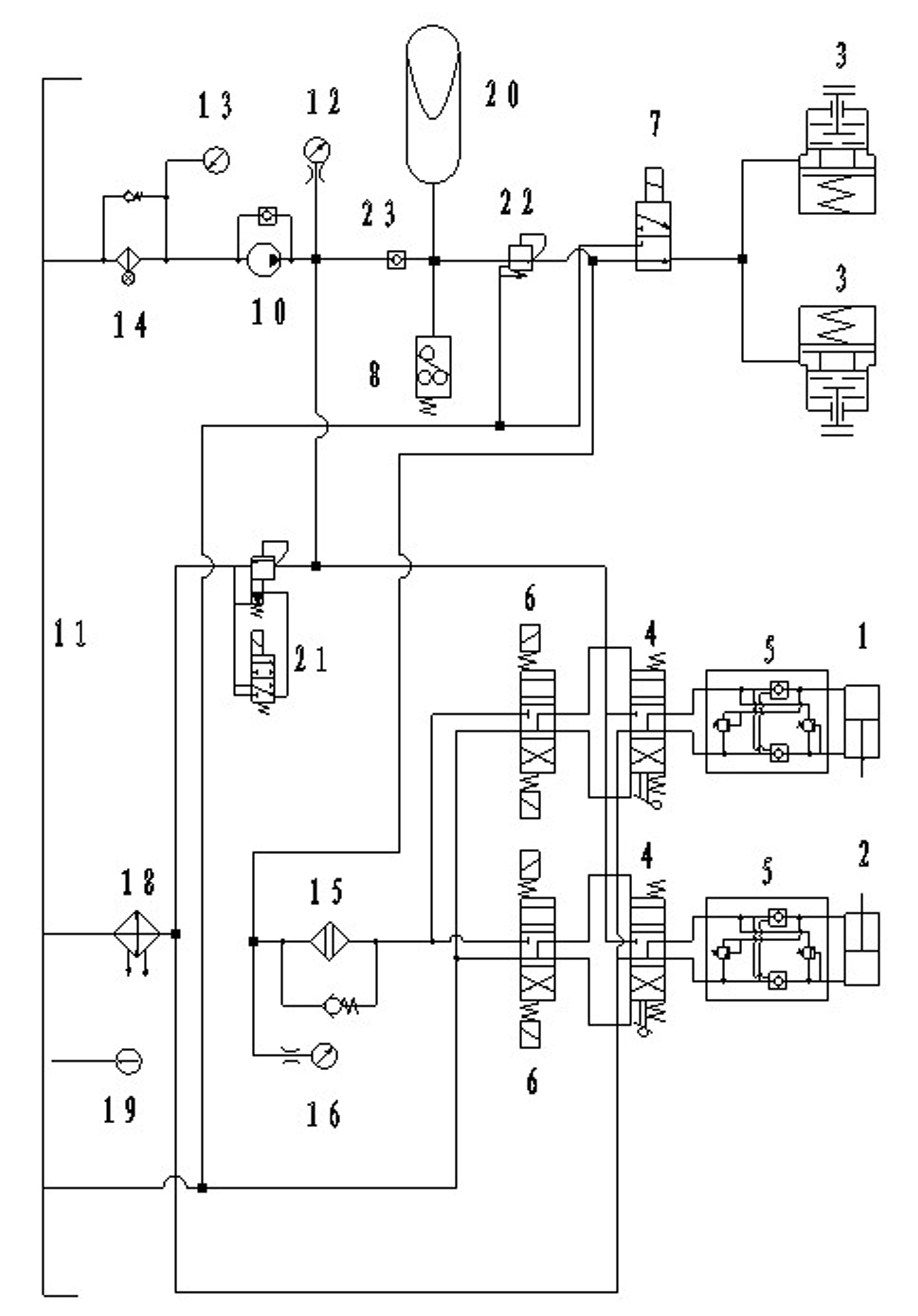

[0030] The hydraulic system of the coal mining machine includes an oil tank 11, an oil pump 10, and several oil cylinder working groups. The oil cylinder working group includes a left height-adjusting oil cylinder working group and a right height-adjusting oil cylinder working group. 1 and the hand hydraulic reversing valve and electromagnetic reversing valve connected with the left height adjustment cylinder 1, the right height adjustment oil cylinder working group includes the right height adjustment oil cylinder 2 and the hand hydraulic reversing valve and electromagnetic reversing valve connected with the right height adjustment oil cylinder 2 The valve is characterized in that the outlet of the oil pump 10 is connected to the accumulator 20, the accumulator 20 is connected to the pressure reducing valve 22, and then connected to the brake 3; the outlet of the accumulator 20 is also connected to each oil cylinder working group connected in parallel, and each oil cylinder ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap