Collecting pipe used for distributing and collecting fluid and molding system comprising such collecting pipe

A header and fluid technology, applied in the direction of mechanical equipment, lighting and heating equipment, pipes/pipe joints/fittings, etc., can solve the problems of lengthy, economical disadvantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

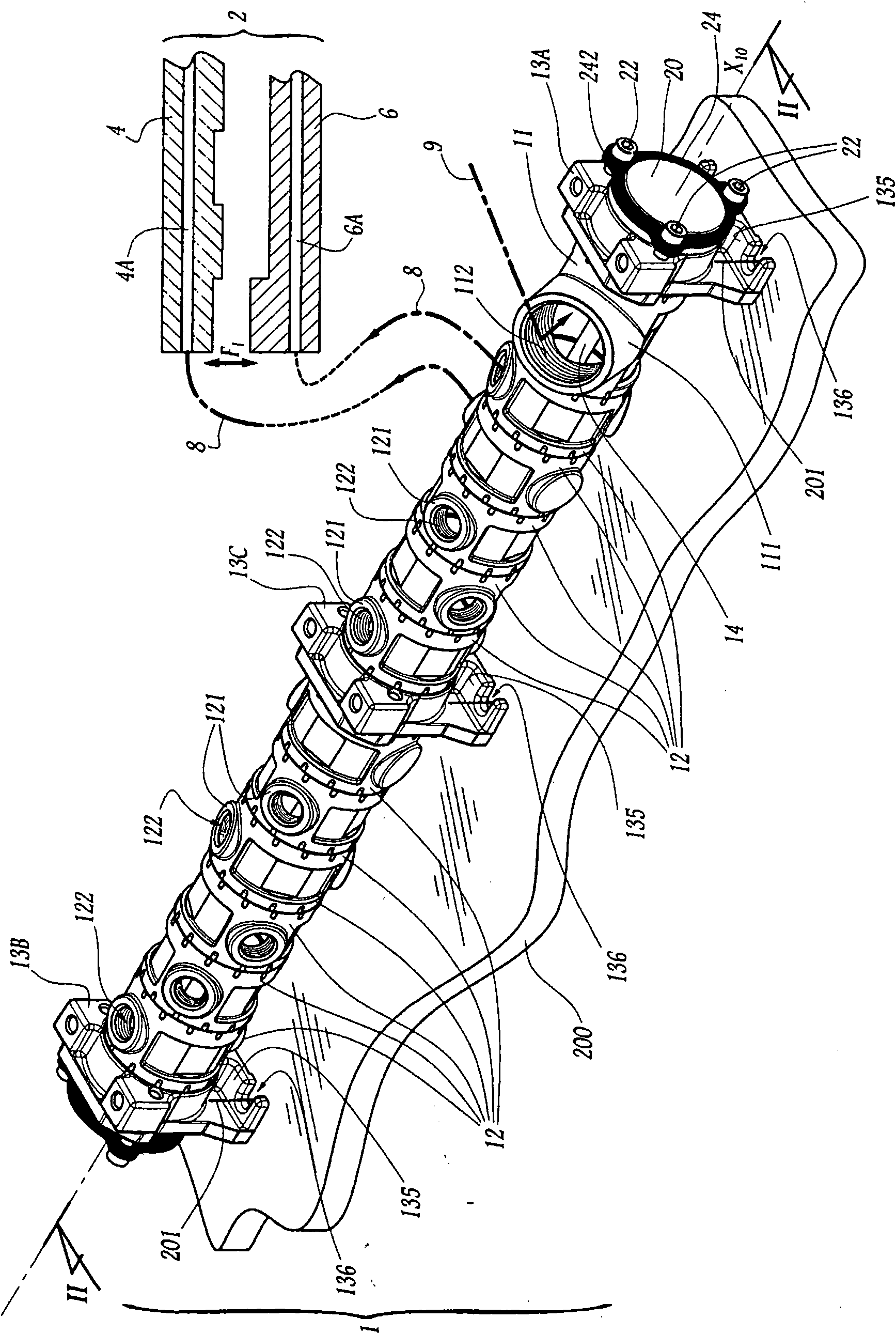

[0031] exist figure 1 The apparatus 1 shown in an incomplete and diagrammatic manner in includes a mold 2 having a die 4 and a cavity 6 mounted for mutual movement as indicated by the double arrow F1 and designed for molding plastic material . In order to keep the plastic material at a temperature suitable for moulding, the die 4 and the cavity 6 are equipped with respective ducts 4A, 6A through which a heat transfer fluid heated to a suitable temperature flows.

[0032] The pipes 4A, 6A are supplied with heat-carrying fluid via hoses 8 , represented by lines indicating their axes, and connected to headers 10 .

[0033] In practice, the plant 1 comprises a plurality of dies of the same type as the die 2, and the header 10 enables the supply of different ducts equipped with the dies and cavities of the different dies, it being conceivable that any one die or cavity can be Equipped with a plurality of such pipes.

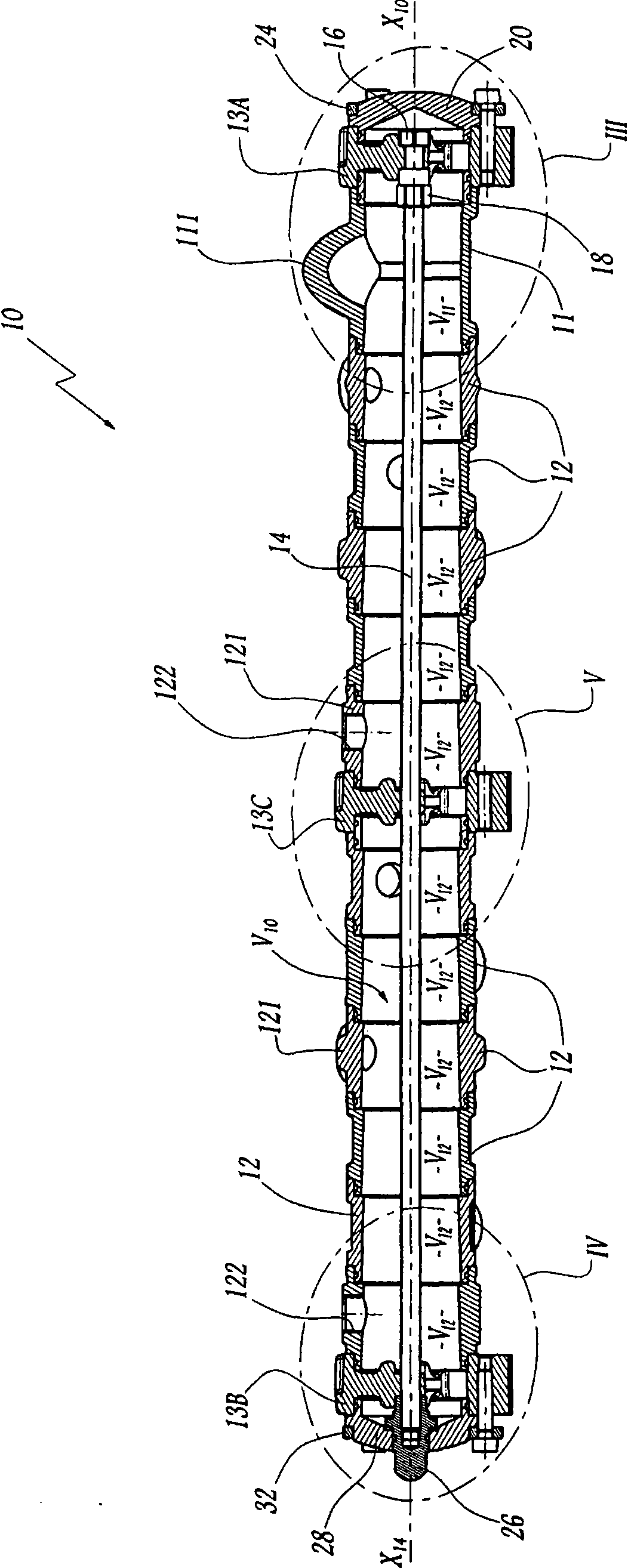

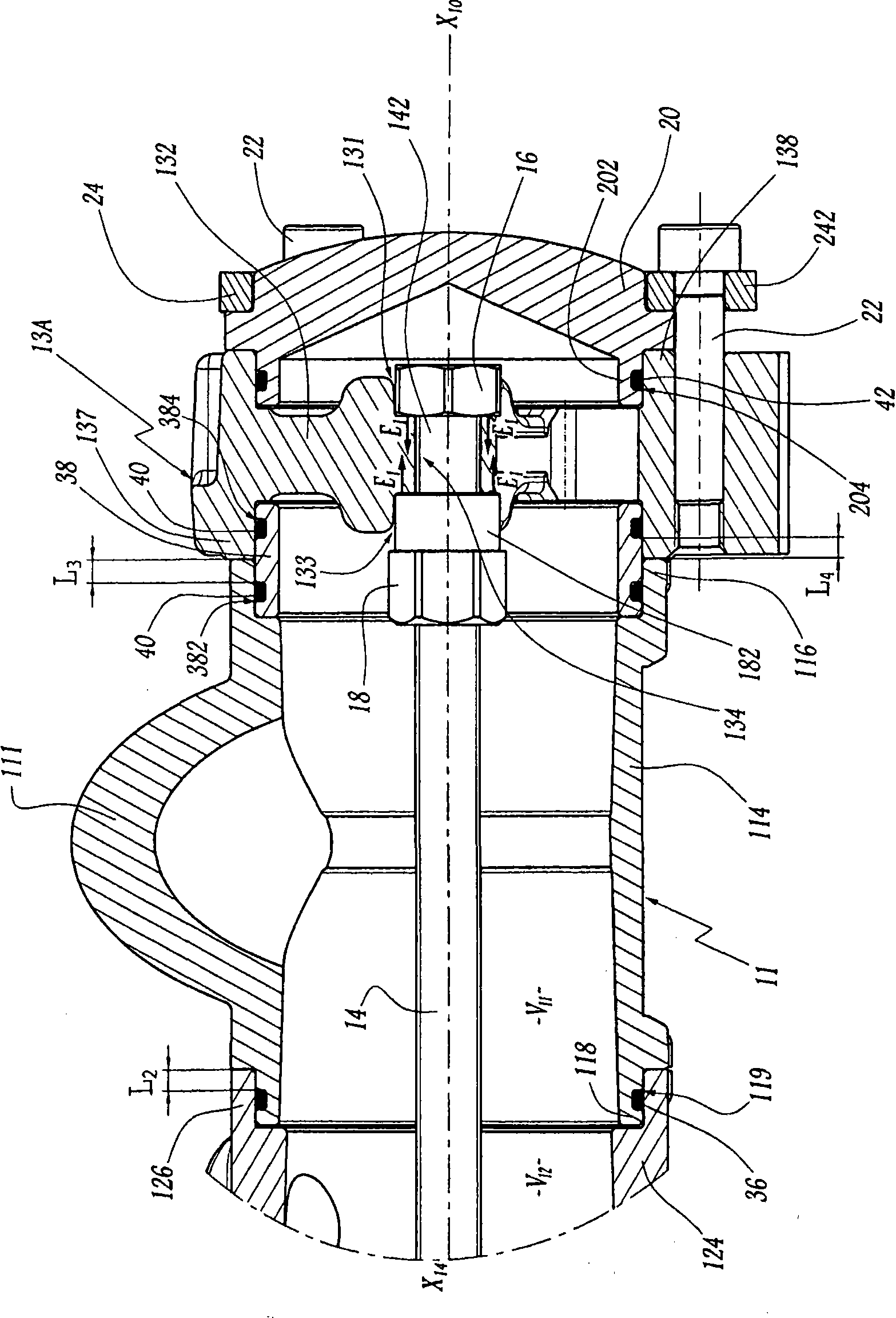

[0034] The header 10 passes along the axis X 10 formed by st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com