A strain-resistant clamp

A technology of tension-resistant clamps and drainage clamps, which is applied in the direction of overhead lines/cable equipment, adjusting/maintaining mechanical tension, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

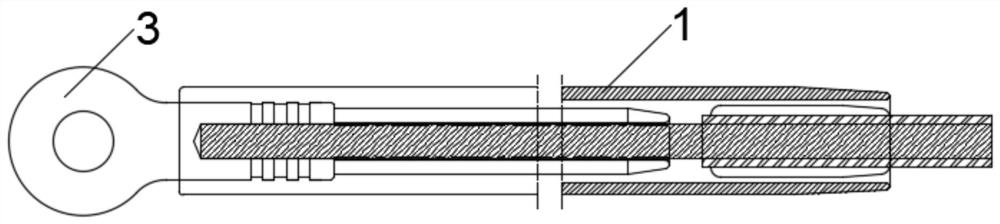

[0058] see Figure 1-5 , an embodiment provided by the present invention: a tension clamp, including a tension clamp, the tension clamp includes a main pipe 1, a steel anchor 3, the main pipe 1 is a hollow structure, the main pipe 1 One end is fixedly connected with the steel anchor 3, and the other end of the main pipe 1 is provided with a first lined aluminum tube 5 and a second lined aluminum tube 6, the first lined aluminum tube 5, the second lined aluminum tube The aluminum tubes 6 are all hollow structures, the first lined aluminum tube 5 is located on the side of the second lined aluminum tube 6 close to the steel anchor 3 in the main body tube 1, and the second lined aluminum tube 6 is provided with reinforced steel pipe 7.

[0059] Preferably, grooves 14 and partitions 15 are arranged on the outer wall of the main body pipe 1, and the grooves 14 and partitions 15 are distributed at intervals, and several grooves 14 and partitions 15 are arranged depending on differen...

Embodiment 2

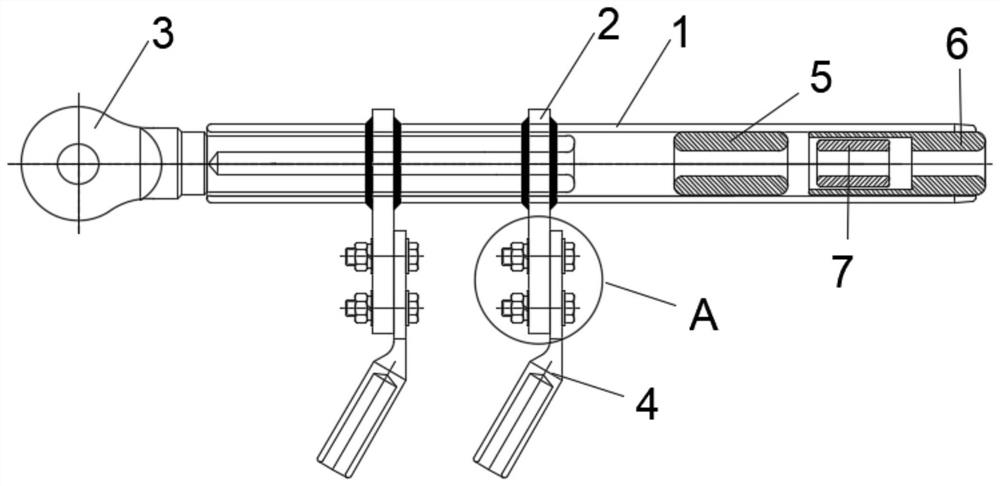

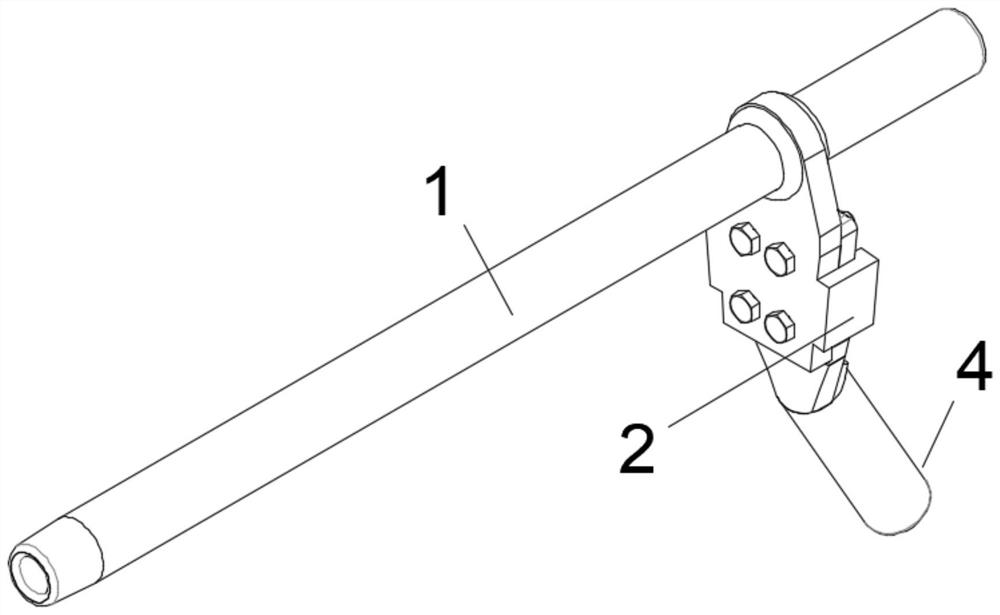

[0064] refer to Figure 6-9 , on the basis of the above-mentioned embodiment 1, a strain clamp includes a strain clamp described in embodiment 1, and also includes a drain plate 2 and a drain clamp 4, and the drain plate 2 is fixed to the On the main pipe 1, the drainage plate 2 and the drainage clamp 4 are provided with bolt holes 8, the drainage clamp 4 is connected with the drainage plate 2 through fastening bolts 9 and nuts 12, and the tightening Flat washers 10 are sleeved on both sides of the drain plate 2 and the drain clamp 4 on the fastening bolt 9 and the nut 12, and a spring washer is also sleeved on the fastening bolt 9 outside the flat washer 10 on the side close to the nut 12 11.

[0065] Preferably, the diversion plate 2 includes a first wedge-shaped plate 201, a C-shaped groove wall 202, and a socket hole 203. The upper side of the first wedge-shaped plate 201 is provided with a socket hole 203, and the socket hole 203 is fixed to the sleeve. Connected to the...

Embodiment 3

[0069] refer to Figure 10-12 , On the basis of the above-mentioned embodiment 2, a quick plug-in device 16 may also be provided in the drainage connection hole 403, and the quick-plug device 16 includes:

[0070] Push block 1601, first linkage 1602, pressure chamber 1603, movable chamber 1604, first spring 1605, first hinged rod 1606, second linkage 1607, second hinged rod 1608, balancer 1609, second spring 1610, Clamping warehouse 1611, first clamping block 1612, second clamping block 1613, synchronous gear 1614, connecting plate 1615, clamping shaft 1616, pressure piece 1617;

[0071] The outer wall of the pressure chamber 1603 is fixed to the drainage connection hole 403, the pressure chamber 1603 is a semi-closed structure, the inside of the pressure chamber 1603 is connected to one end of the first spring 1605, and the inner side of the pressure chamber 1603 is a movable chamber 1604, the first linkage 1602, the second linkage 1607, the first hinged rod 1606, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com