Rotor shaft for an electric machine and electric machine

A technology for rotor shafts and steering parts, applied in the manufacture of stator/rotor bodies, electromechanical devices, electrical components, etc., can solve problems such as cooling fluid friction loss, achieve high design freedom, reduce inertia, and provide design freedom Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

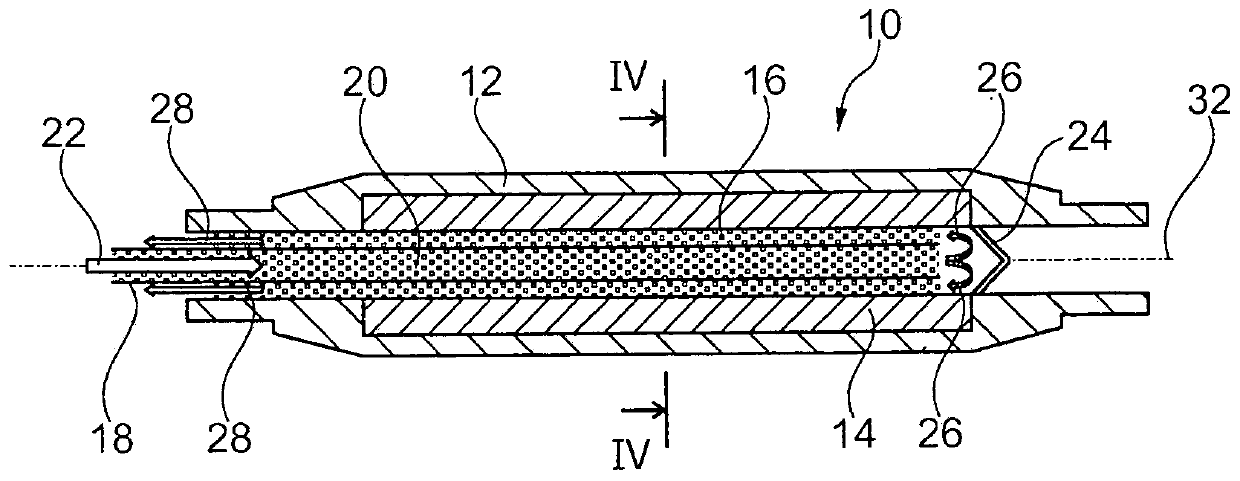

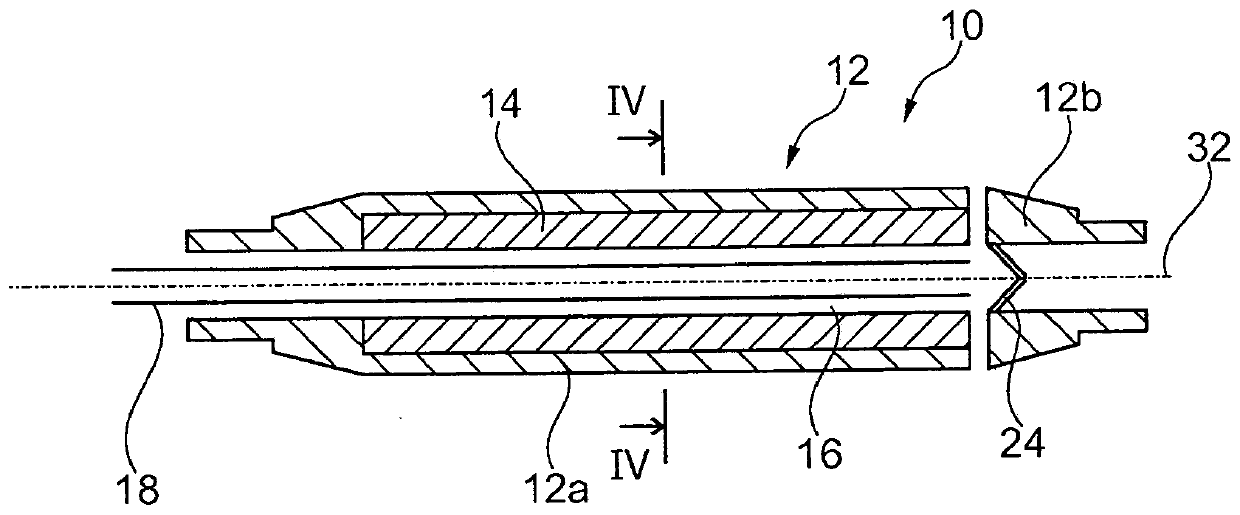

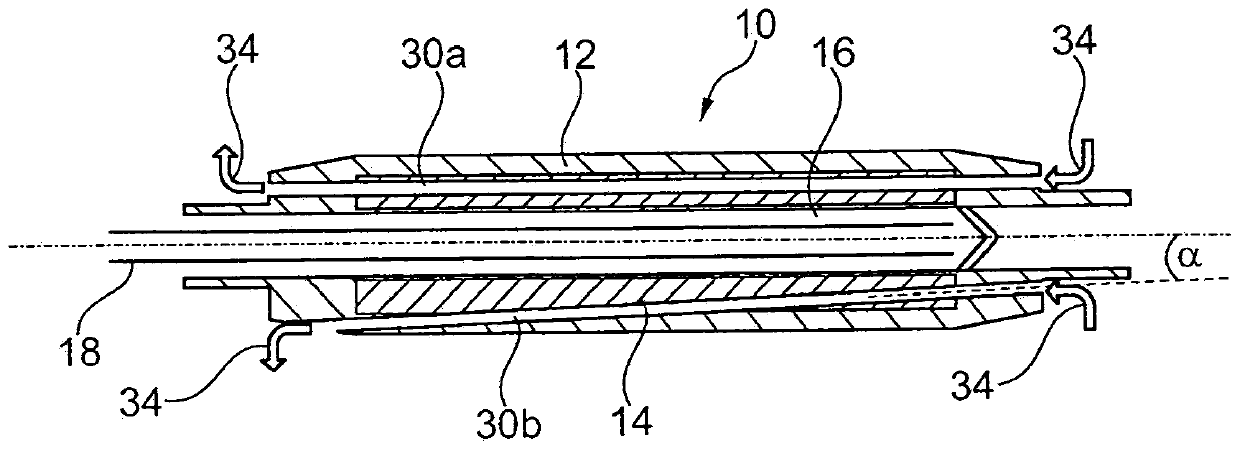

[0033] figure 1 A rotor shaft 10 for an electric machine (not shown in detail) is shown, comprising a rotor shaft base body 12 and a rotor shaft core 14 arranged in the rotor shaft base body 12 and connected to the rotor shaft base body 12 .

[0034] Furthermore, a cooling chamber 16 is provided in the rotor shaft 10 , which in the embodiment shown is an approximately axial central bore.

[0035] A cooling fluid nozzle 18 is inserted into the cooling chamber 16 , through which cooling fluid 20 is introduced into the cooling chamber 16 . The insertion direction is indicated by arrow 22 .

[0036] The cooling chamber 16 extends essentially continuously in the rotor shaft 10 , but is delimited at the end facing away from the cooling fluid nozzle 18 by a cooling fluid deflector 24 . This cooling fluid deflector deflects the cooling fluid 20, as indicated by the arrow 26, so that the cooling fluid exits the cooling fluid again on the same side of the rotor shaft 10 on which the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com