Easy-maintaining LED module

A technology of LED modules and LED chips, which is applied in the parts of lighting devices, lighting and heating equipment, electrical components, etc., can solve the problems of incomplete, unclear, and low maintenance efficiency of the display screen, and improve maintenance safety, The effect of simplifying maintenance procedures and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

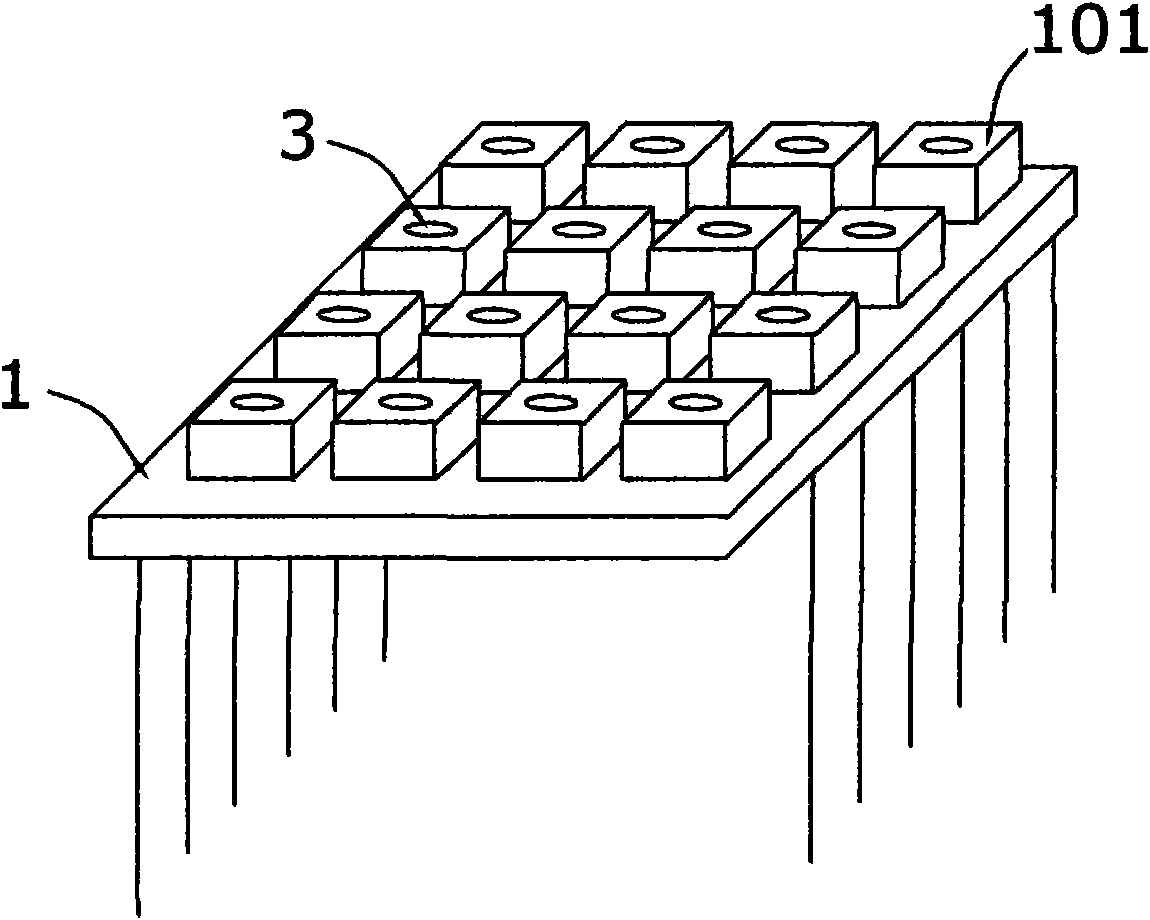

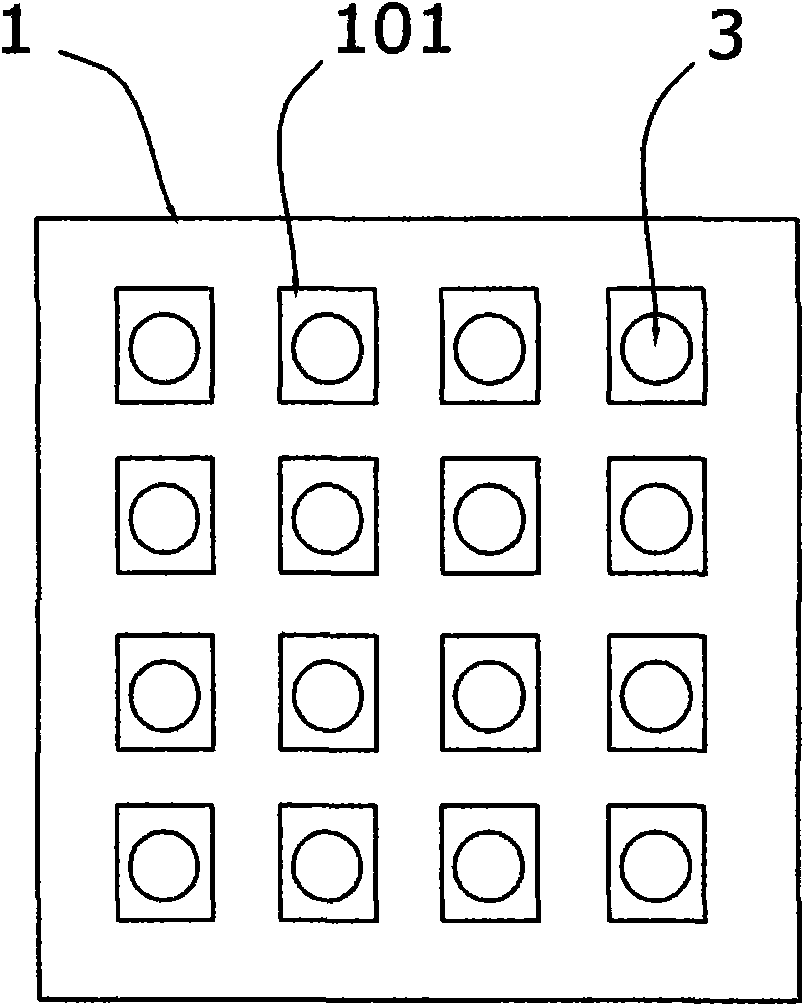

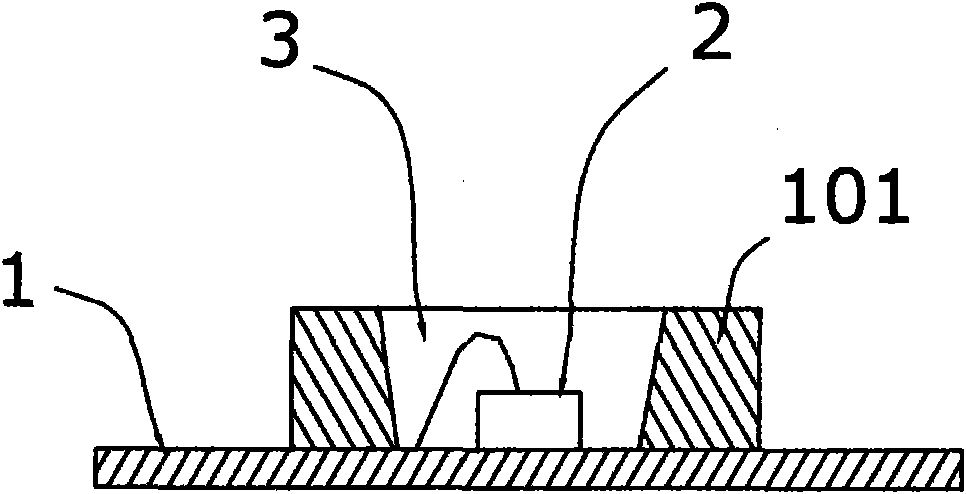

[0020] Such as Figure 1 ~ Figure 4 As shown, the circuit module 1 is provided with a matrix of light spots composed of several reflective cups 101; the reflective cup 101 whose inner wall is a conical surface is provided with an LED bonding pad 102 and a pad 103 of an LED lamp covered and protected by the reflective cup 101 ; The center vertical line of both ends of the reflective cup 101 coincides, and an LED chip 2 in the reflective cup 101 is electrically connected to the wire bonding pad 102, and the wire bonding pad 102 is electrically connected to the pad 103, and the pad 103 is located at the bottom edge of the reflective cup 101 position, the reflective cup 101 is filled with a layer of encapsulant 3 to form the LED lamp illuminant of the present invention; the LED chip 2 in the reflective cup 101 has at least one luminescent color; when multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com