Anti-explosion lamp

An explosion-proof lamp and protective cover technology, applied in the field of explosion-proof lamps, can solve the problems of short lamp life and serious light decay, and achieve the effects of enhanced heat dissipation performance and increased area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

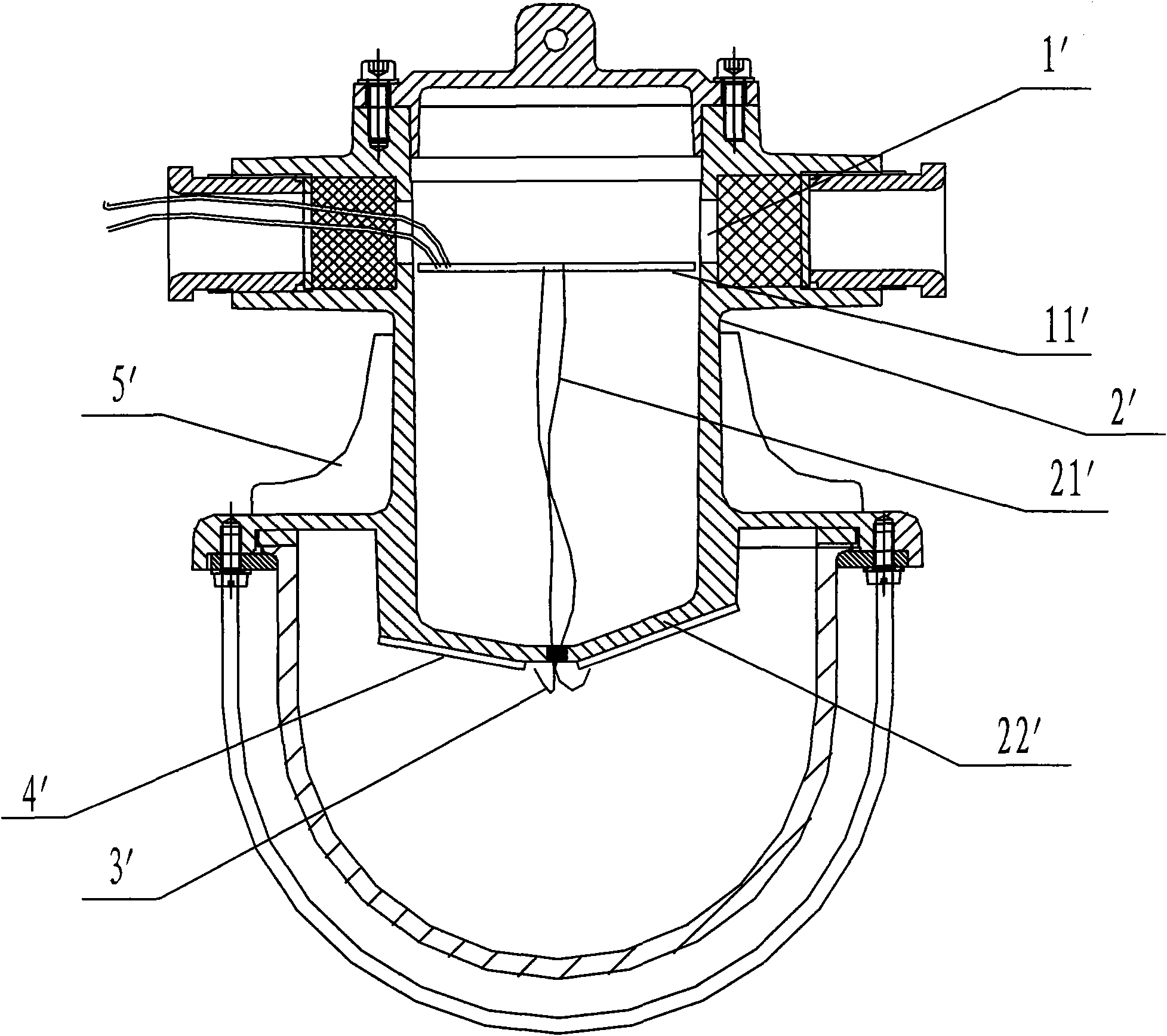

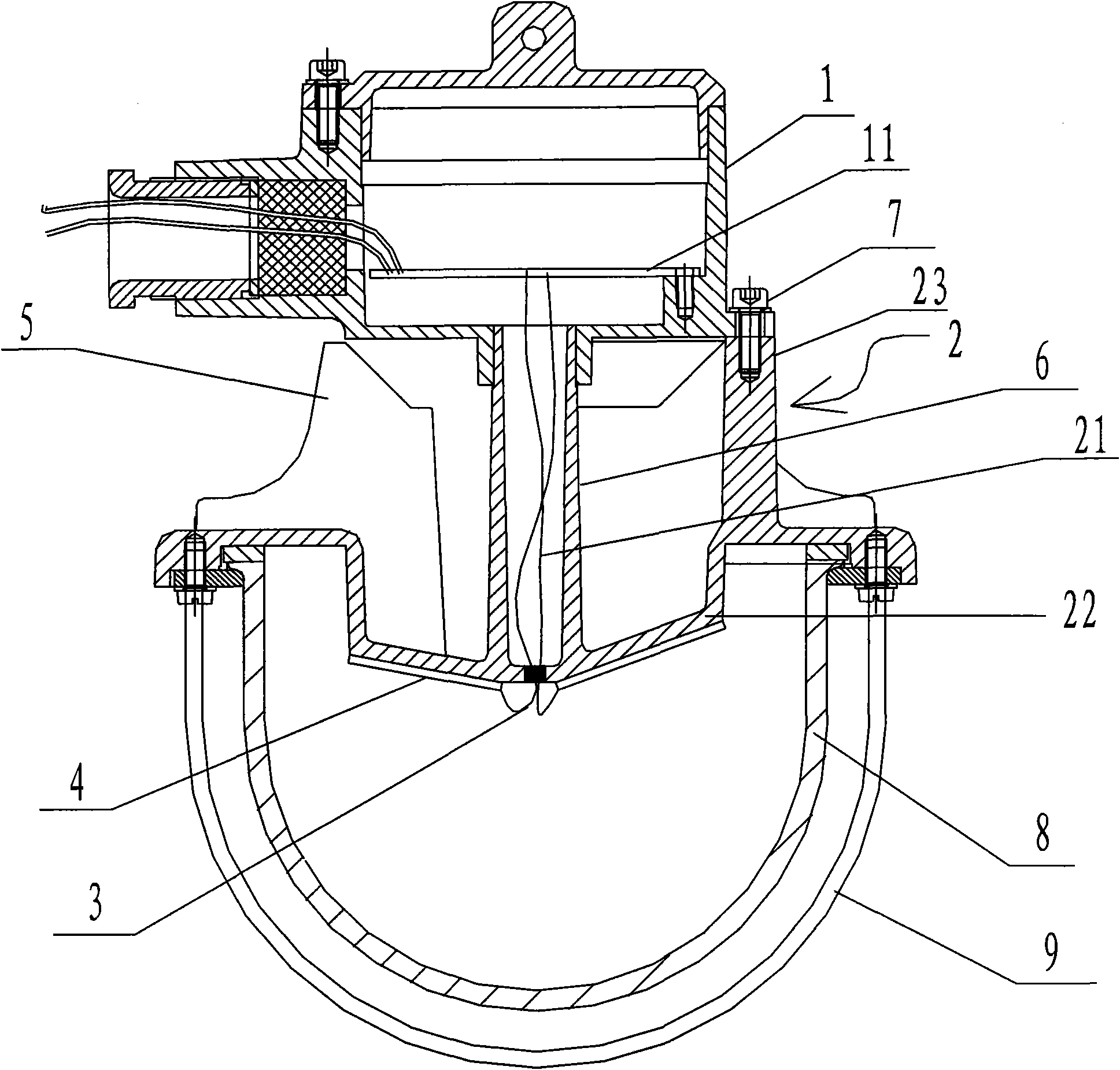

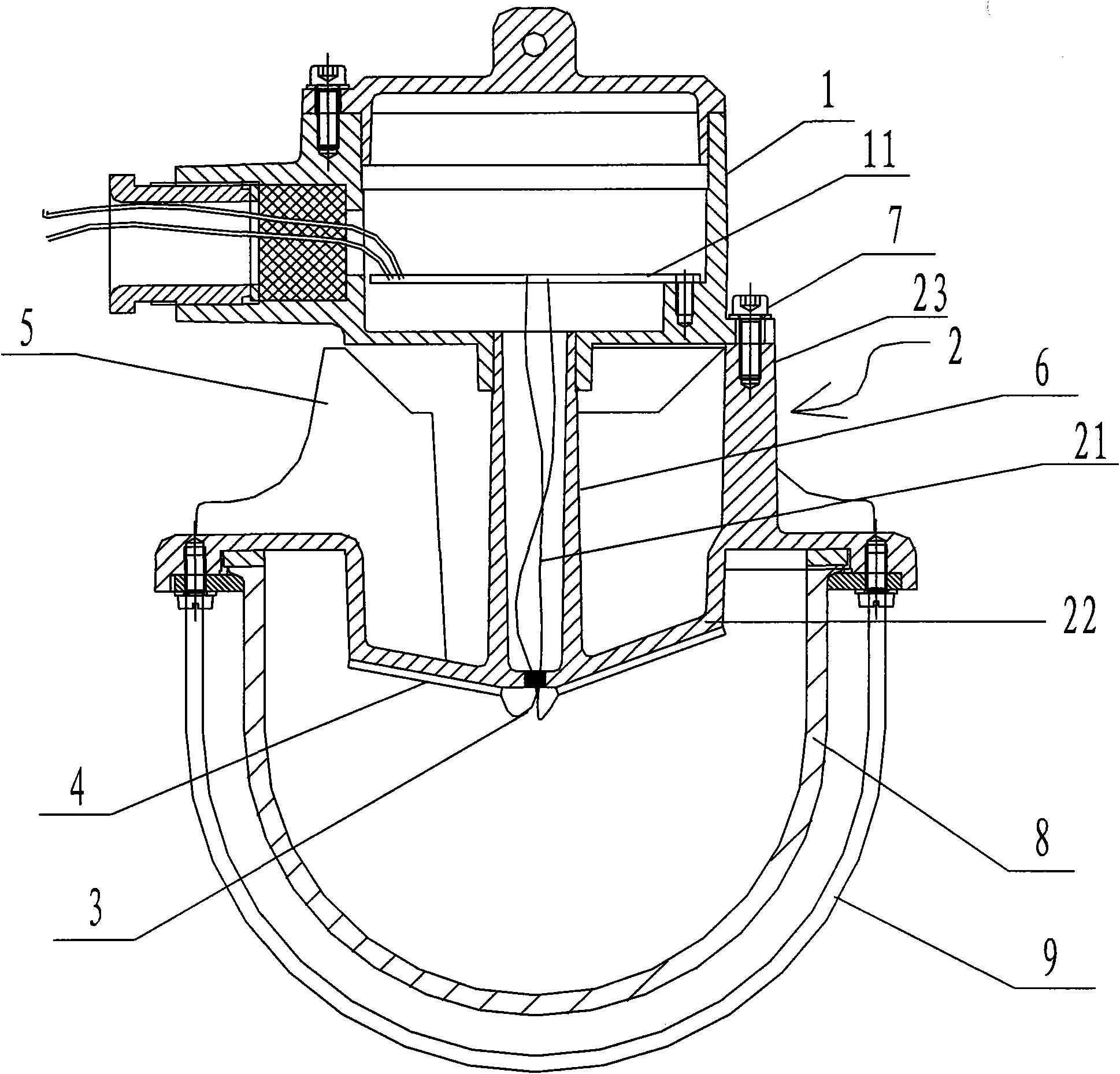

[0018] Such as figure 2 As shown, the explosion-proof lamp provided by the present invention includes the main body including the electrical appliance housing 1 and the light source housing 2 . Electrical components 11 are arranged inside the electrical appliance casing 1, and light source wires 21 are arranged inside the light source casing 2. The electrical appliance casing 1 is connected to the light source casing 2, and the end of the light source casing 2 far away from the electrical appliance casing 1 is the bottom casing. 22. A light source board 4 and LEDs 3 arranged on the light source board 4 are arranged on the outer side of the bottom shell 22 . The electrical components 11 are connected to the light source board 4 through the light source wires 21 .

[0019] Of course, the explosion-proof lamp provided by the present invention also includes two layers of protective covers arranged outside the bottom shell 22 and surrounding the LED 3 , the outermost layer is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com