Novel megawatt wind generating set testing system and testing method thereof

A technology of wind power generating set and test system, which is applied in the direction of motor generator testing, measuring electricity, and measuring electrical variables, etc. Problems such as the inability to monitor the test status in real time, achieve strong compatibility and scalability, and meet the multi-faceted and test-required effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

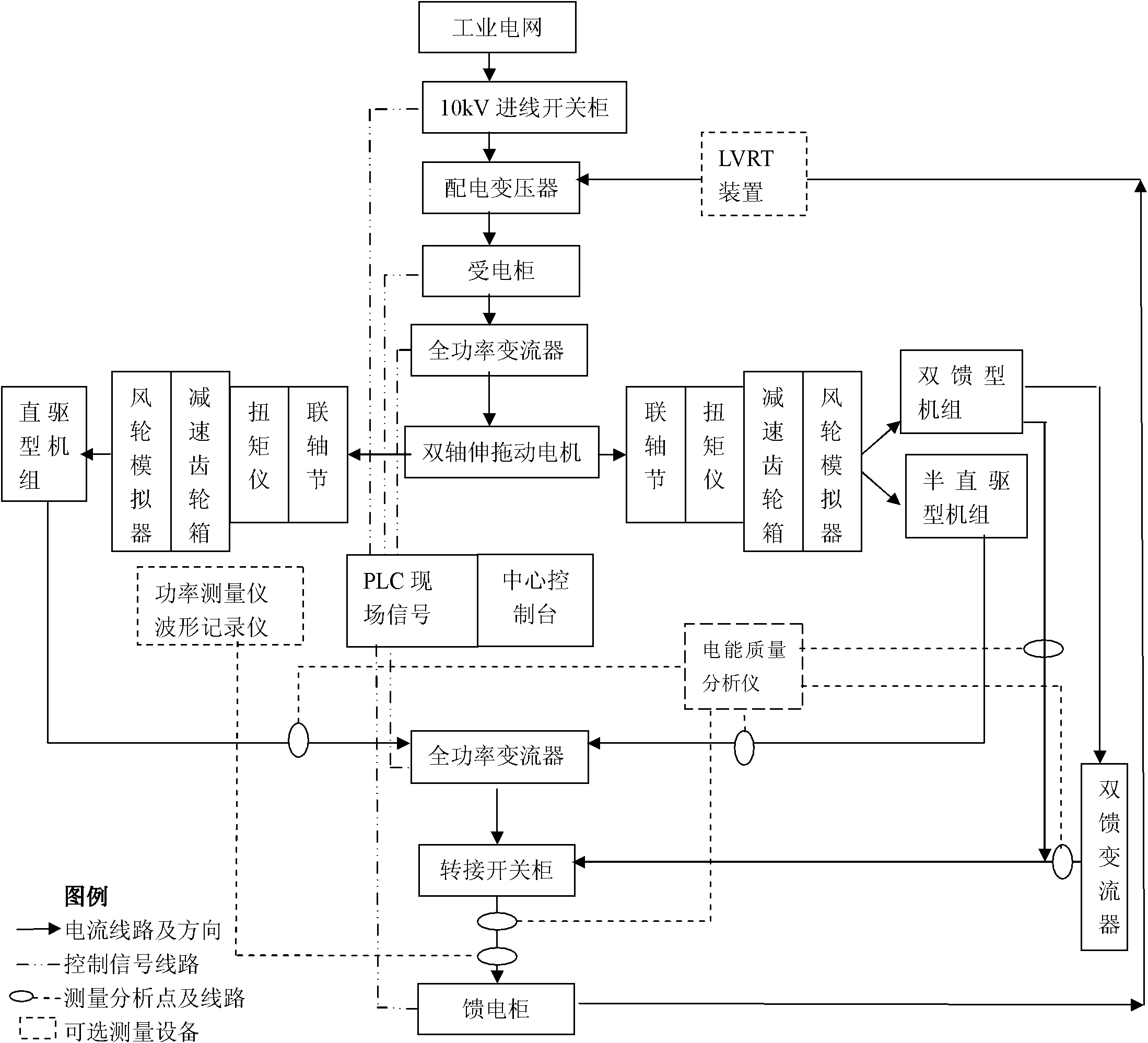

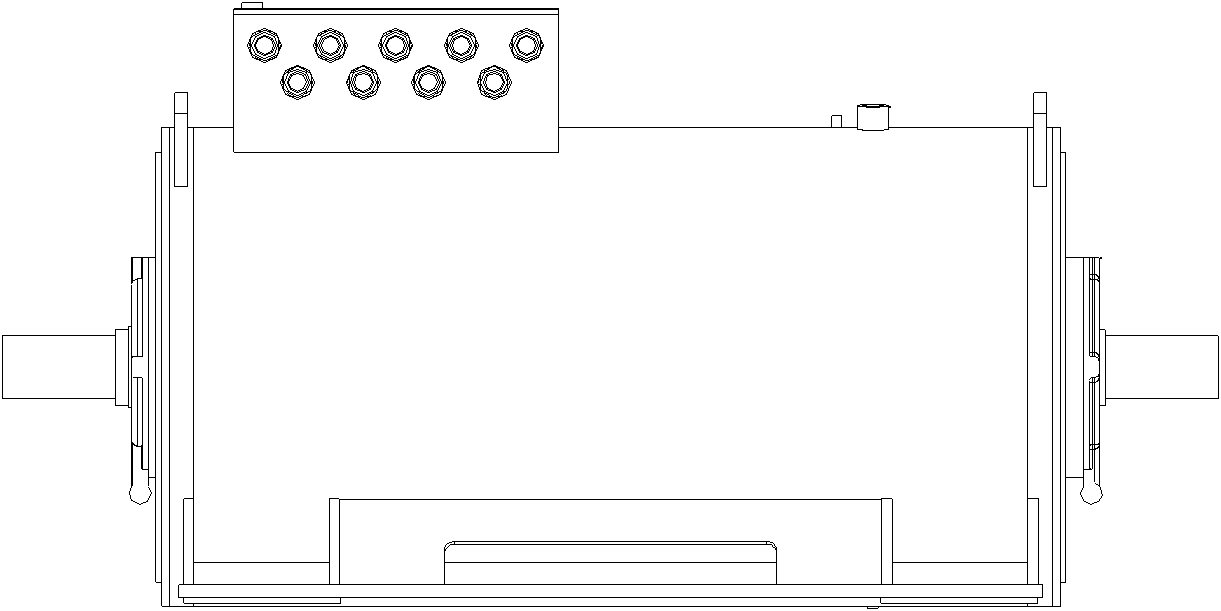

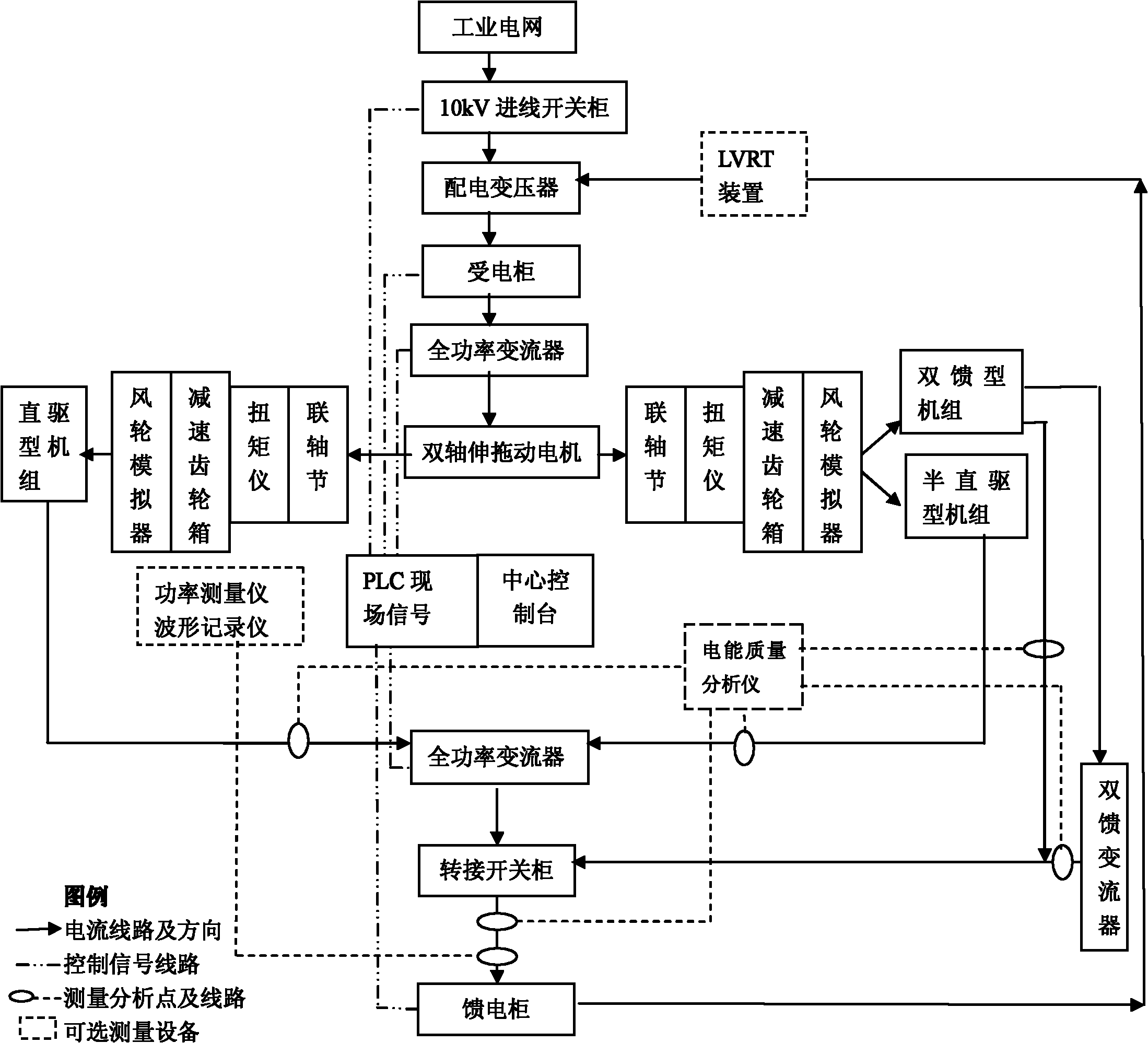

[0008] Below in conjunction with accompanying drawing, the present invention is described in further detail: see figure 1 with 2 , a megawatt-level wind turbine test system, the system includes 10kv incoming switchgear, distribution transformers, power receiving cabinets, full power converters, double-shaft extension drag motors, couplings, torque meters, reducers Gearboxes, wind turbine simulators, converters (different converters are used for different units), transfer switch cabinets, feeder cabinets, plc, central consoles, power quality analyzers, power measuring instruments, waveform recorders, etc. Measuring equipment; the industrial power grid is connected to the distribution transformer through a 10kv incoming switch cabinet, and the distribution transformer reduces the voltage to 690V to supply the power receiving cabinet and the full-power converter to drive the drag motor; the two ends of the drag motor ( One end) can also be connected to the coupling, torque meter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com