Ethylene cracking severity modeling method based on expert knowledge and neutral network

A neural network model and ethylene cracking technology, applied in the interdisciplinary field of chemical engineering and information science, can solve problems such as difficult cracking furnace work, short residence time, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

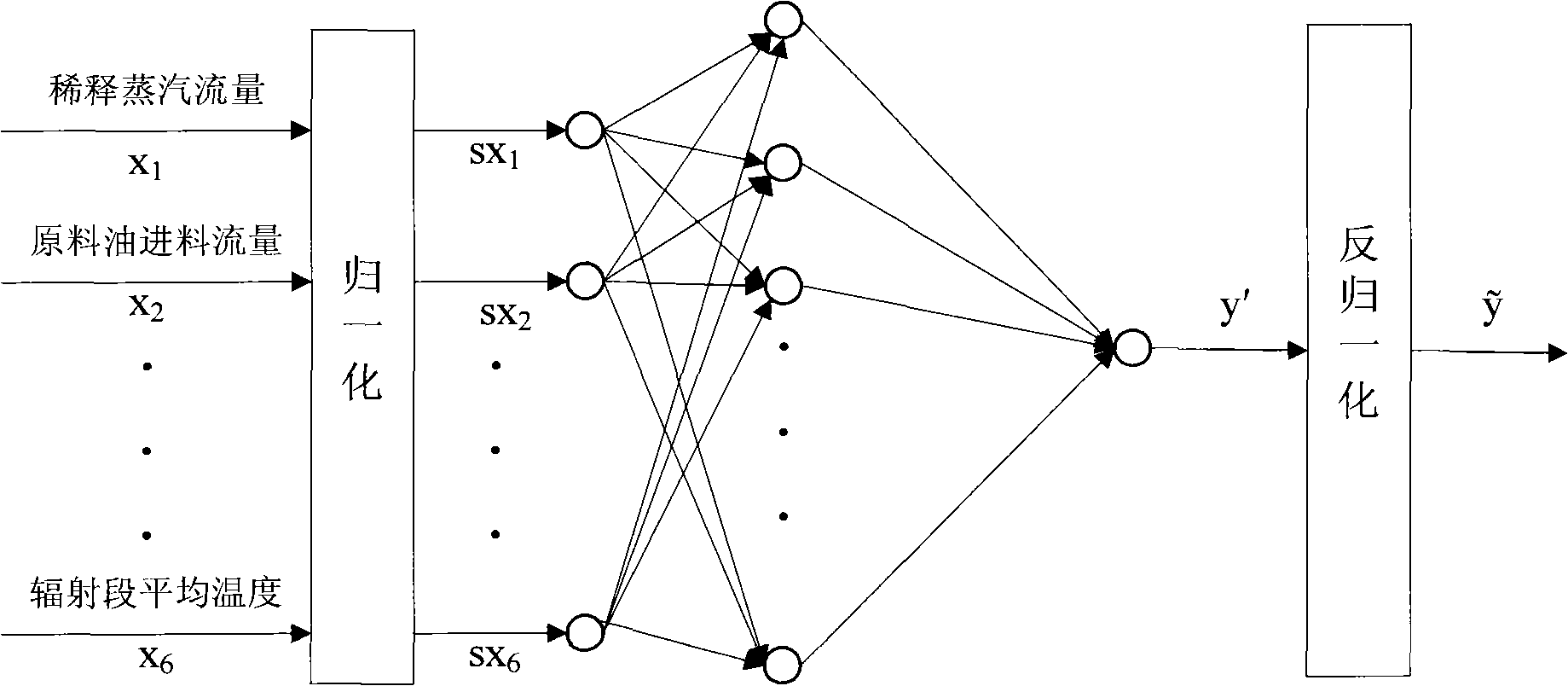

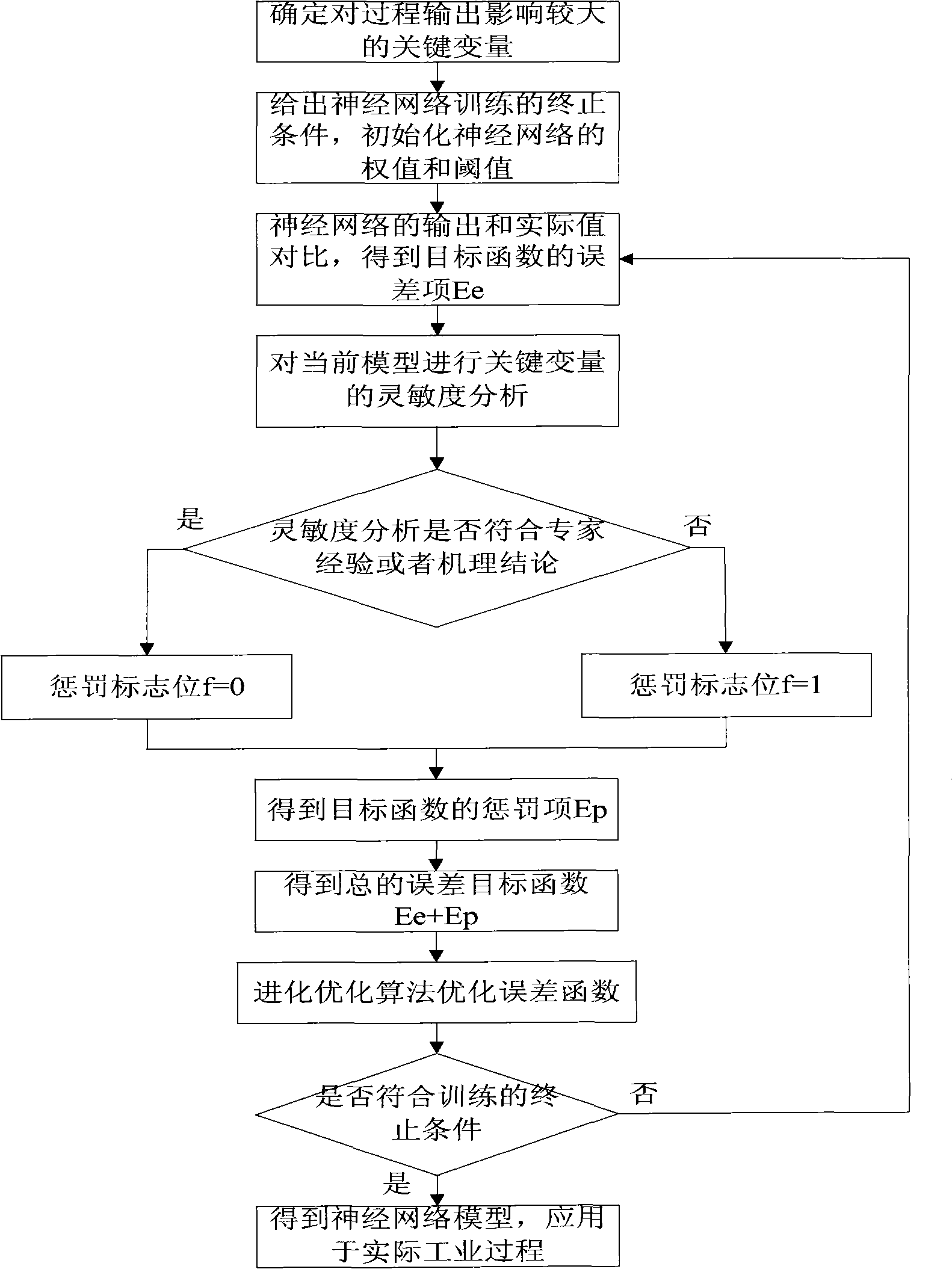

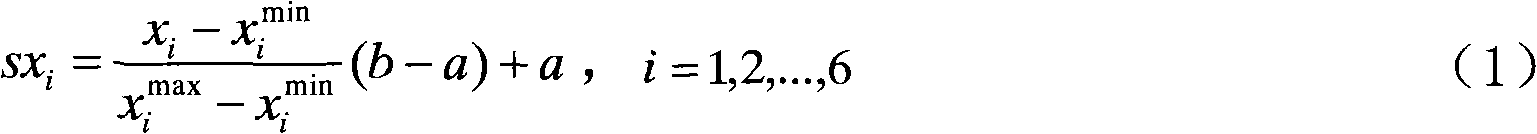

[0030] use as figure 1 In the shown neural network structure, the variables affecting the depth of ethylene cracking are determined first: dilution steam flow rate (x 1 , kg / h), cracking furnace feed load (x 2 , kg / h), raw oil density (x 3 ,kg / m 3 ), the average temperature at the furnace tube outlet (x 4 , ℃), the average temperature of waste heat boiler outlet (x 5 , ℃), the average temperature of the radiation section (x 6 , ℃). In this example, the key input variable dilution steam flow rate x 1 , Feed load of cracking furnace x 2 and the average temperature at the outlet of the furnace tube x 4 Do a sensitivity analysis. Therefore, according to the above variables, the number of input layer nodes of the neural network is determined to be 6, the number of hidden layer nodes is set to 8, and the number of output layer nodes is 1. The hidden layer activation function uses the tansig function, and the output layer activation function uses the logsig function.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com