Stator coil end encapsulating and fixing method

A technology of stator coil and fixing method, which is applied to laying solid insulation and embedding prefabricated windings into motors, etc., can solve the problems affecting the service life and wear of the motor, and achieve the effects of easy maintenance, weight reduction and excellent overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

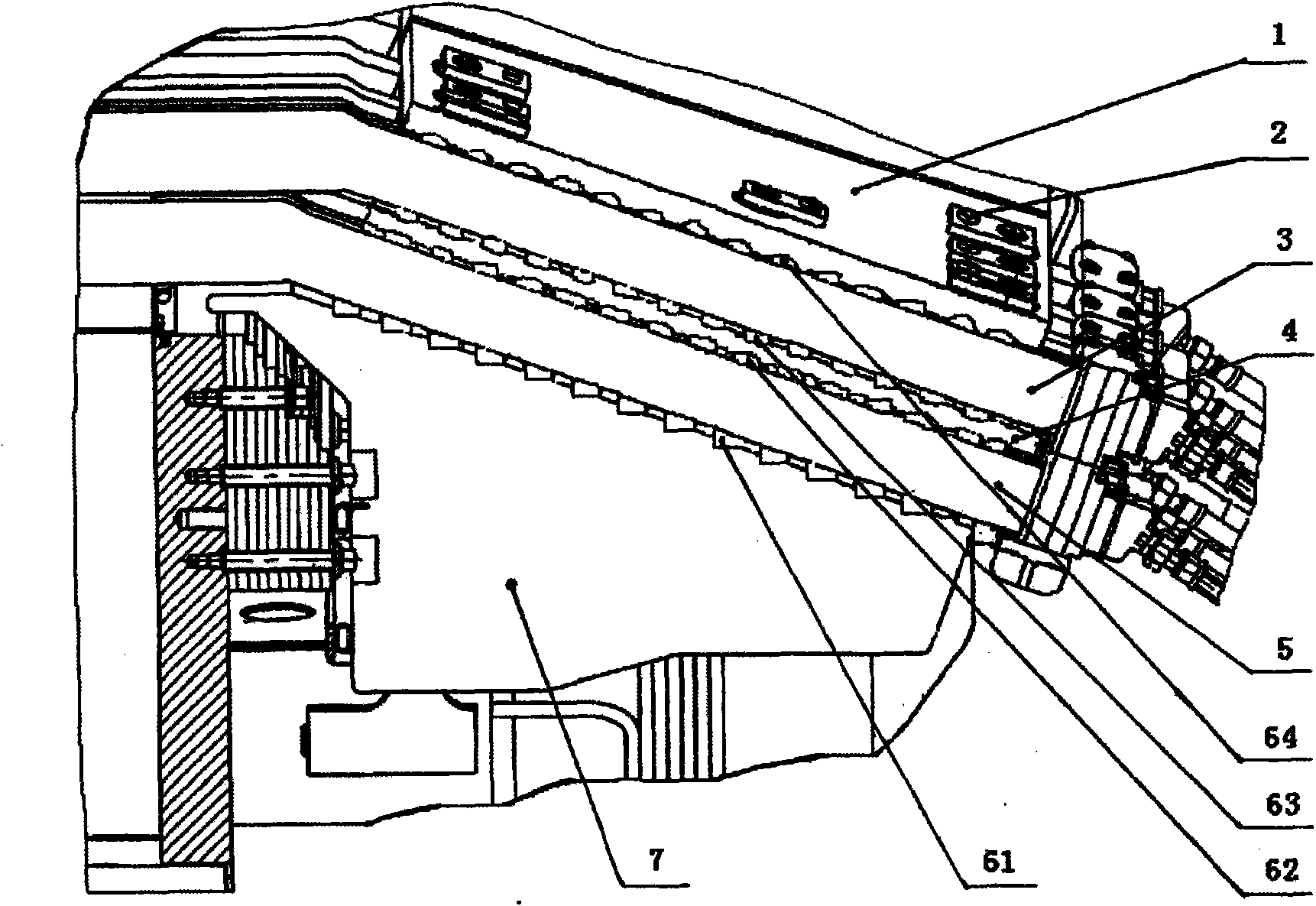

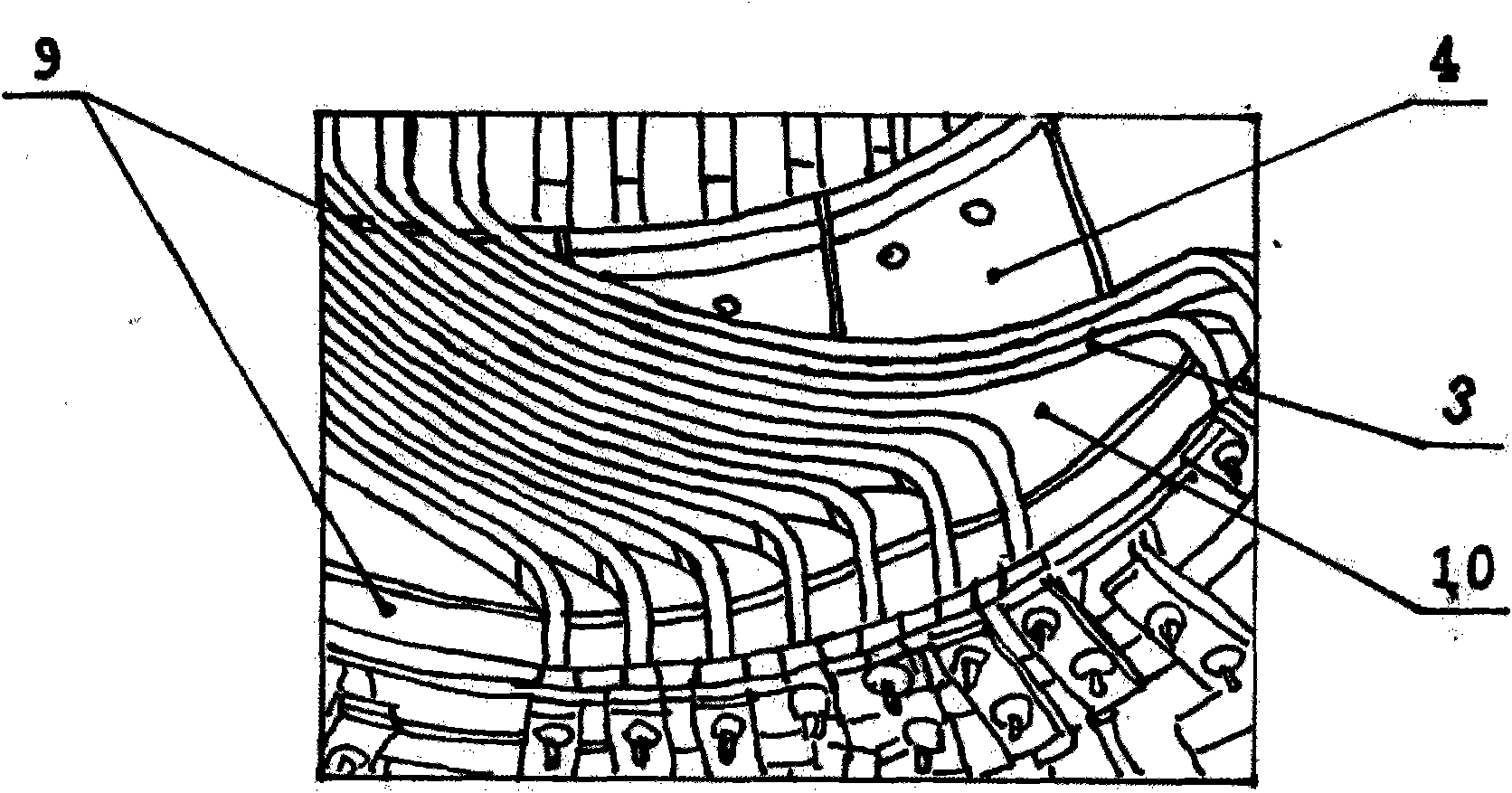

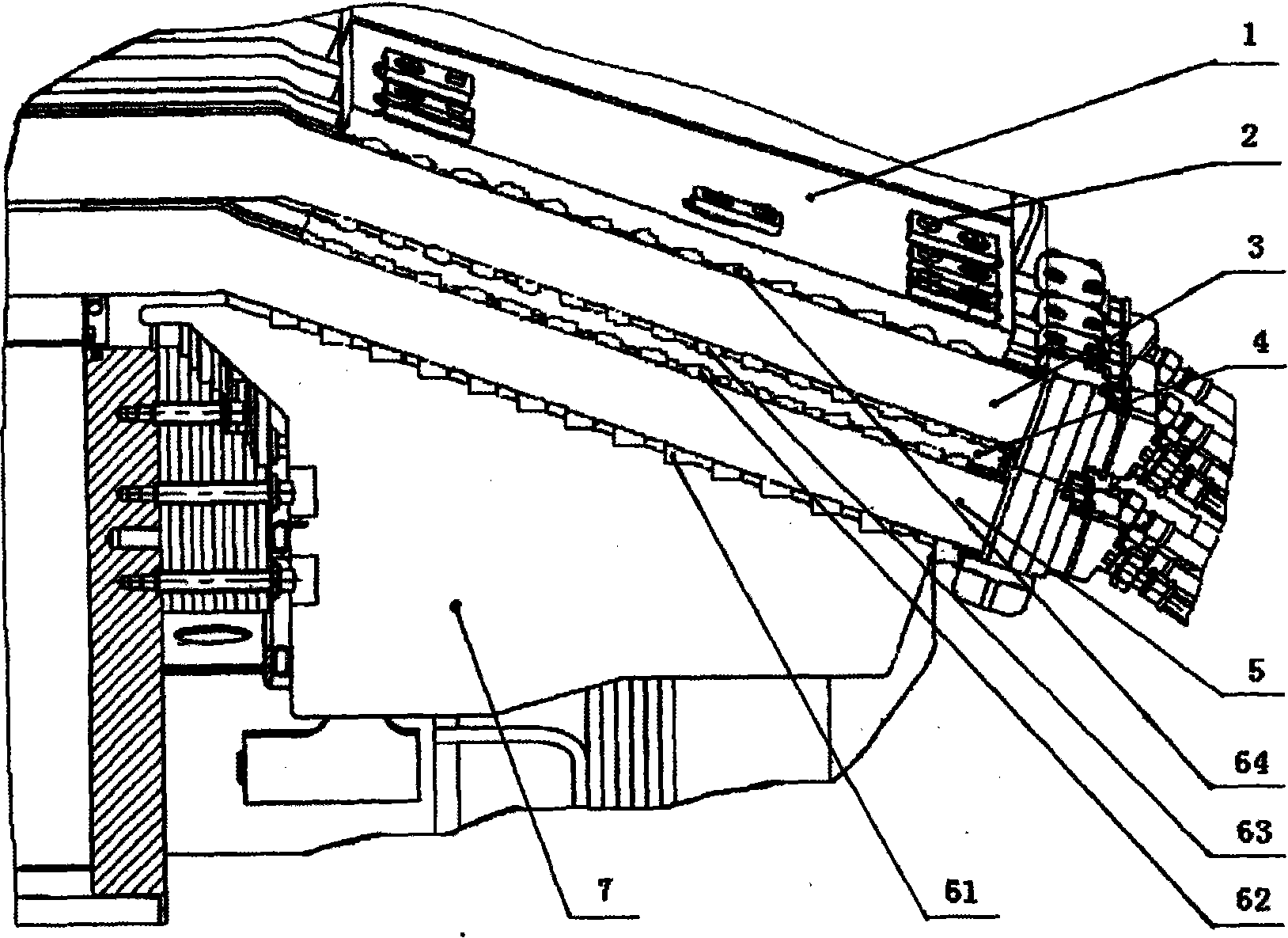

[0018] Such as figure 1 As shown, it is a schematic diagram of fixing the coil at the end of the stator. The large cone ring 7 is fixed at the end of the stator coil, and the resin rope is laid on the inner side of the large cone ring 7 to form the first resin rope layer 61. The lower layer wire rod 5 is arranged on the first On the resin rope layer 61, the ends of the lower wire rods 5 are half-wrapped in one layer with a polyethylene release tape, and the ends of the lower wire rods 5 are embedded in the first resin rope layer 61. Stoppers 9 are set between the lower wire rods 5, and epoxy resin potting glue 10 is poured between the lower wire rods 5 in the same phase and the separated phase. Epoxy resin potting glue 10 at the height of 1 / 3-1 / 2 of the lower wire rod 5, air-dry for 2-5 hours, pour the remaining height and scrape it, and air-dry for 24 hours;

[0019] Resin ropes are laid on the lower wire rod 5 to form the second resin rope layer 62, interlayer arc-shaped pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap