Method for improving saline-alkali land by partitioning salt with interlayer

A saline-alkali land and salt isolation technology, which is applied in the direction of soil preparation methods, applications, agricultural machinery and implements, etc., can solve the problems of small applicable space, etc., and achieve the effects of reducing salt return, good economic benefits, and moderate investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

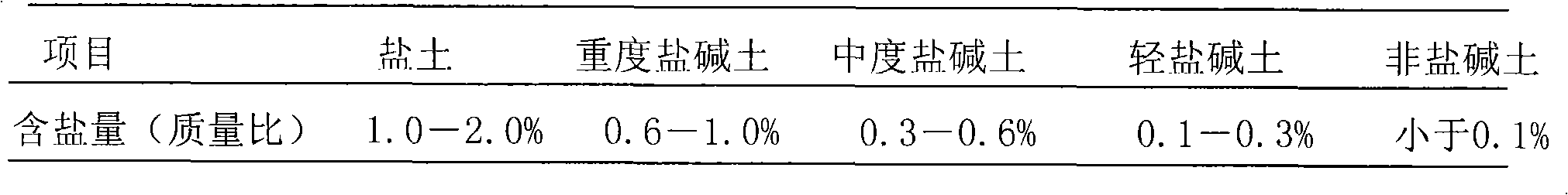

[0029] A certain saline-alkali land is 200 mu, and the mass ratio of salt content is 0.92%. According to the classification standard of saline-alkali soil, it is severe saline-alkali soil. The way to improve it is: use an excavator to dig out and remove the 350-400mm thick soil layer from the surface to the surface, then level the ground, and lay sand about 60-70mm thick and 1-3mm in particle size After leveling, backfill 350-400mm of non-saline-alkali soil and mix 1,000kg of humic acid soil. Before sowing, add 3,000kg / mu of manure and use 50kg / mu of ferrous sulfate soil improver. Plant corn in that year, and the yield per mu is 600kg. .

Embodiment 2

[0031] The salt content of a certain saline-alkali land is 0.41%, which is moderate saline-alkali soil according to the classification standard of saline-alkali soil. The way to improve it is: use an excavator to dig out and remove the 150-200mm soil layer from the surface to the surface, then level the ground, lay 20-30mm thick, 5-10mm diameter gravel, and backfill after leveling 300-350mm of non-saline-alkali soil, enough organic fertilizer should be applied before sowing, and 45kg / mu ferrous sulfate soil amendment should be used, and agricultural production can be carried out in that year.

Embodiment 3

[0033] A saline-alkali land has a salinity mass ratio of 0.19%, which is classified as light saline-alkali soil according to the classification standard of saline-alkali soil. The way to improve it is: use an excavator to dig out and remove the 50-80mm soil layer from the surface to the surface, then level the ground, first lay gravel with a thickness of 10-20mm and a diameter of 3-10mm, and then Lay 10-20mm thick sand on the gravel, and then backfill 300-350mm of non-saline-alkali soil, apply enough organic fertilizer before sowing, and use 30kg / mu ferrous sulfate soil improver, and agricultural production can be carried out in that year.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com