Flange coiling machine

A bending machine and flange technology, applied in the field of profile forming equipment, can solve the problems of low work efficiency and poor bending effect around the flange, and achieve the effects of easy operation, ensuring aesthetics and good forming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

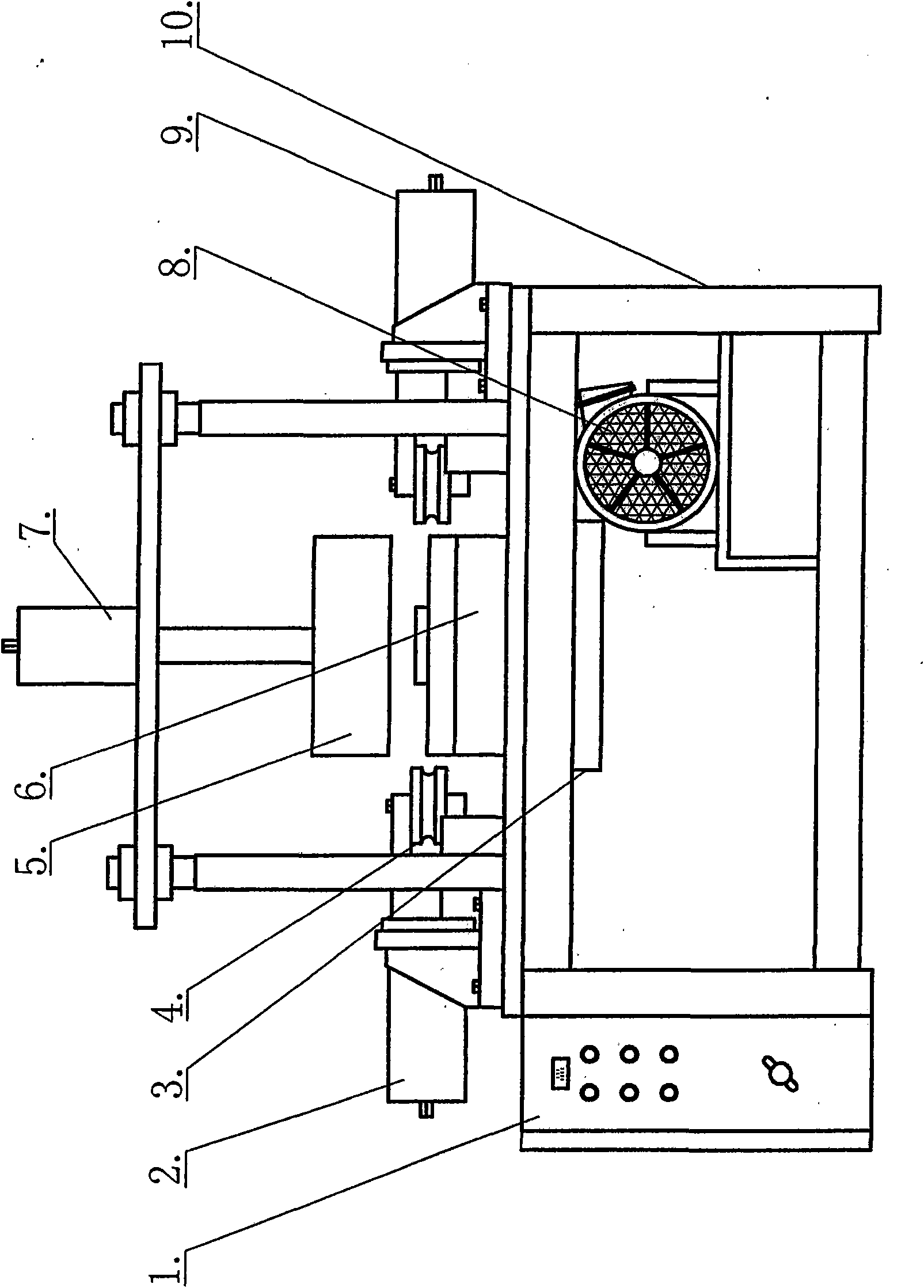

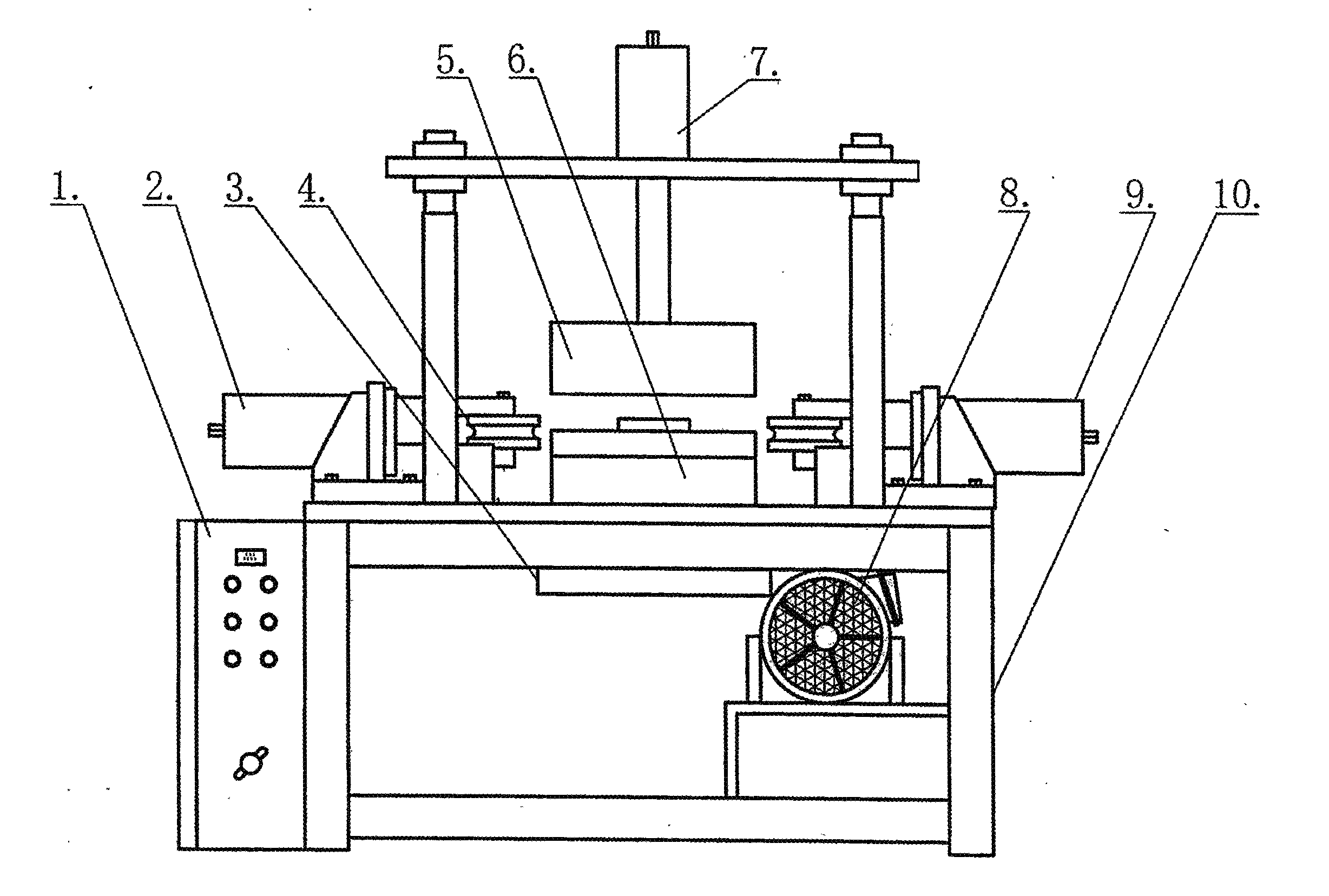

[0009] Such as figure 1 Shown, the present invention is provided with control box 1 at one end of frame 10, and motor 8 is located in frame 10, is provided with left bending oil cylinder 2 and right bending oil cylinder 9 at frame 10 tops, at one end of two bending oil cylinders respectively A volume of bending wheel 4 is provided, and the bottom of the upper compression oil cylinder 7 is provided with an upper compression disc 5 , and the lower clamping disc 6 is located on the frame 10 and corresponds to the upper compression disc 5 .

[0010] The working principle is, when working, place the processing flange on the lower clamping plate 6, start the upper clamping oil cylinder 7 to move the upper clamping plate 5 down, the flange is clamped and fixed, and the motor 8 drives the clamping through the gear box 3 The disc rotates at high speed, and then the bending wheel 4 is moved to the corresponding position through the action of the left and right bending cylinders, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com