Automatic ladle covering and uncovering system for metal smelting

A technology of metal smelting and uncovering, which is applied to metal processing equipment, lighting and heating equipment, furnace types, etc., can solve problems such as major accidents, unstable working conditions, and easy breakage, and achieve high reliability, Compact structure and ingenious design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

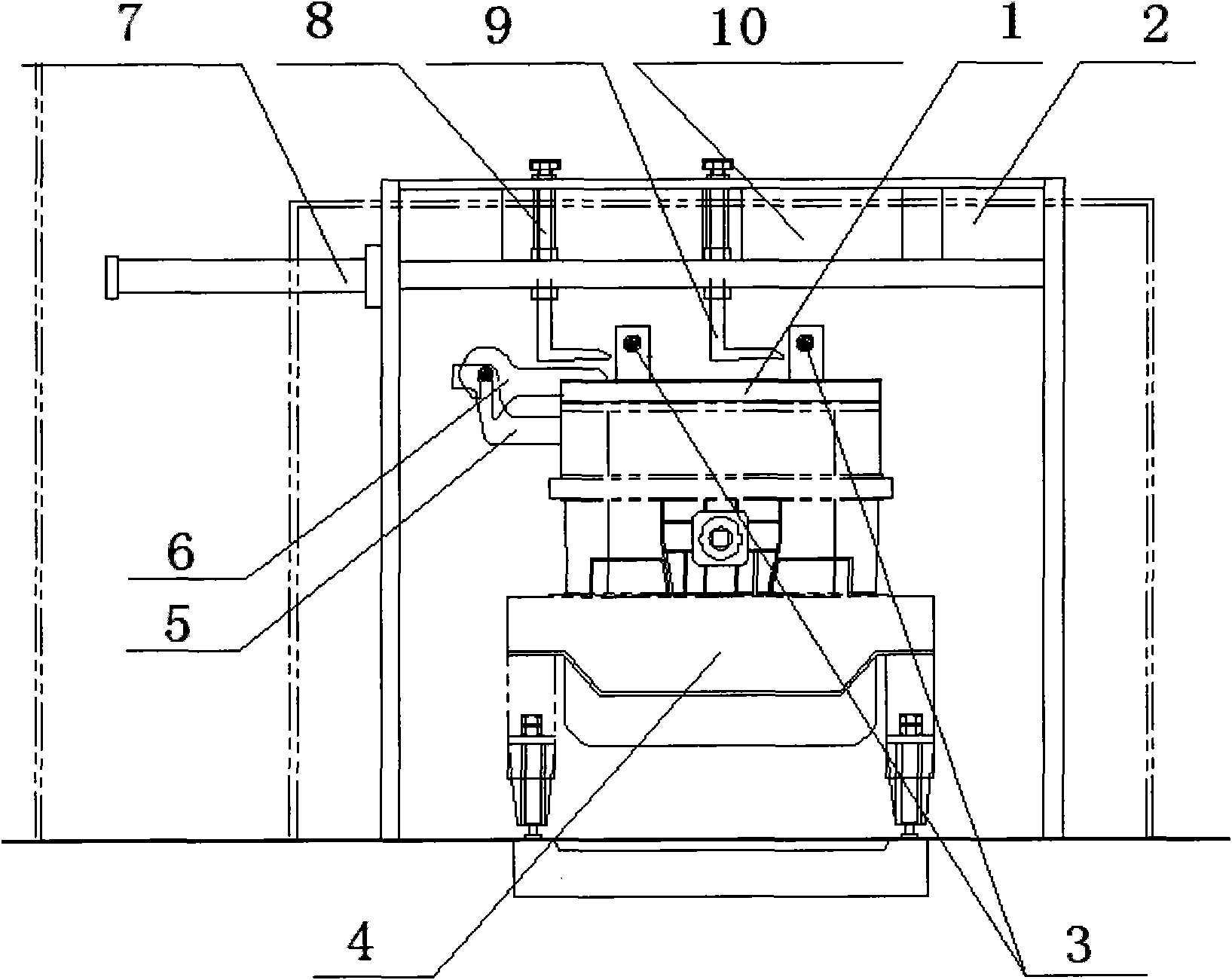

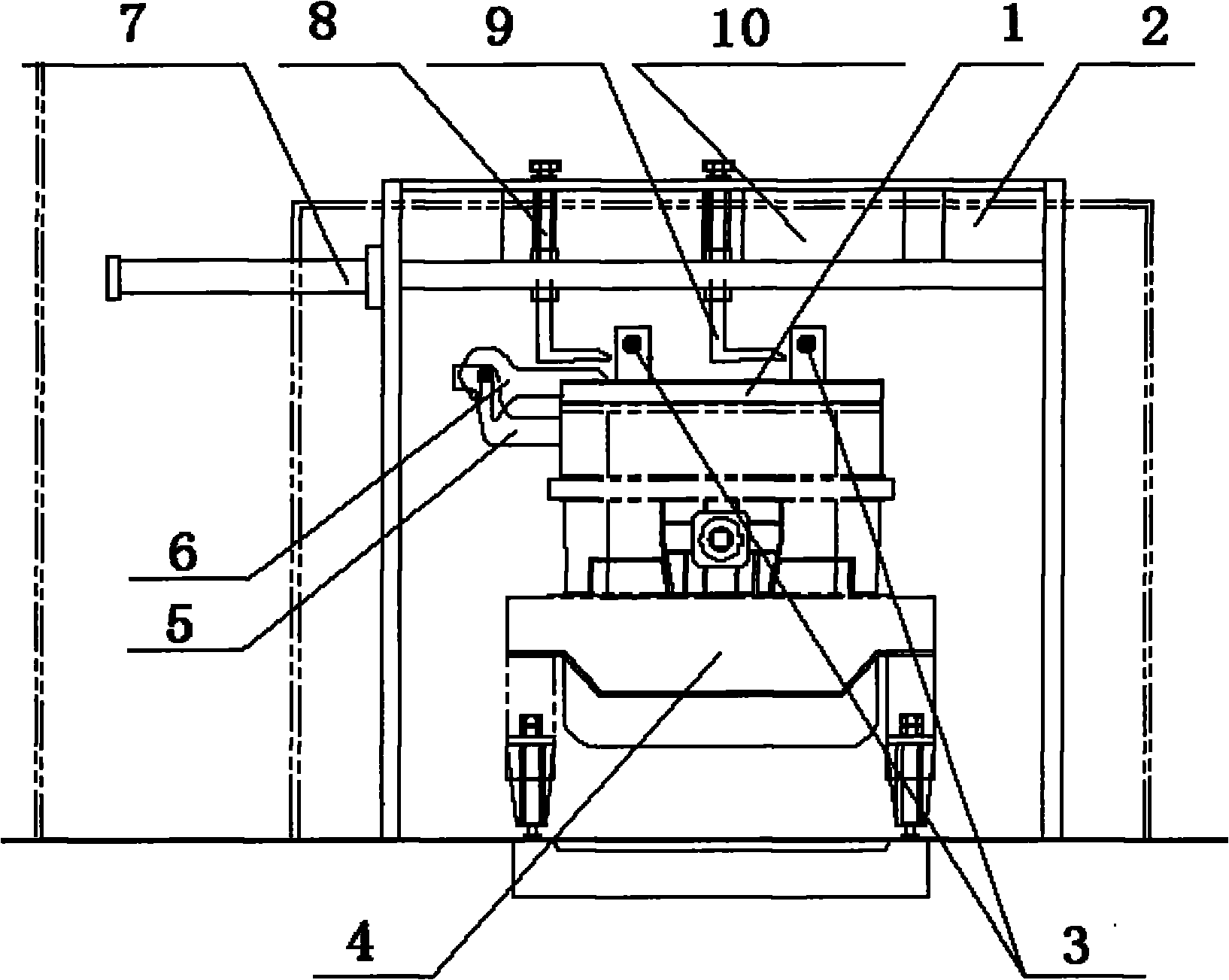

[0027] Such as figure 1 As shown, the technical solution provided by the present invention is an automatic ladle capping system applied in metal smelting, including a ladle cap 1 and a ladle capping mechanism 2, and the cylinder cap is provided with a lifting roller 3 , the ladle adding and uncovering mechanism 2 is provided with a moving platform, and the moving platform is provided with an inclined slide plate 9 in contact with the lifting roller 3 . The mobile platform includes a push-pull mobile platform oil cylinder 7 and an inclined slide plate mobile platform 10, the push-pull mobile platform oil cylinder 7 is connected with the inclined slide plate mobile platform 10; the inclined slide plate 9 is arranged on the inclined slide plate mobile platform 10; Described steel ladle adds and uncovers mechanism 2 and is also provided with lifting oil cylinder 8, and described lifting oil cylinder 8 links to each other with described inclined slide plate 9; One end of the incli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com