Packaging and stacking dedicated pallet

A technology of stacking and palletizing, which is applied in the field of container stacking special pallets, which can solve the problems of occupying commodity transportation space, increasing labor intensity of workers, increasing commodity costs, etc., and achieves the effects of reducing labor intensity, improving loading efficiency, and using safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

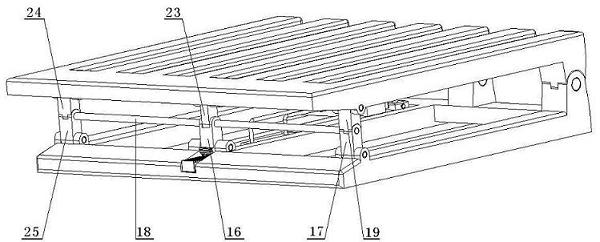

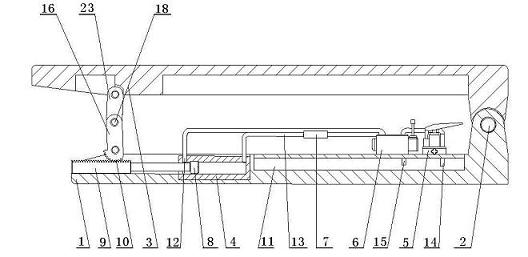

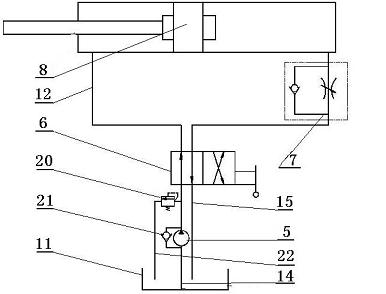

[0021] The schematic diagram of the container stacking special pallet of the present invention is as follows Figure 1-4 As shown, it includes an upper pallet 3 and a lower pallet 1, one end of the upper pallet 3 and the lower pallet 1 is hinged by a pin 2, and the other end is connected by a flexible support mechanism. The active support mechanism includes a fuel tank 11, an oil cylinder 4, a two-position four-way reversing valve 6, a manual oil pump 5, a lower active active support rod 16, an upper active active active support rod 23, and a rack 9. The oil cylinder 4 is provided with The piston 8 moving along the width direction of the lower pallet, the piston rod connected to the piston 8 is fixedly connected with the rack 9, and the rack 9 is placed on the upper surface of the lower pallet 1 along the width direction of the lower palle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap