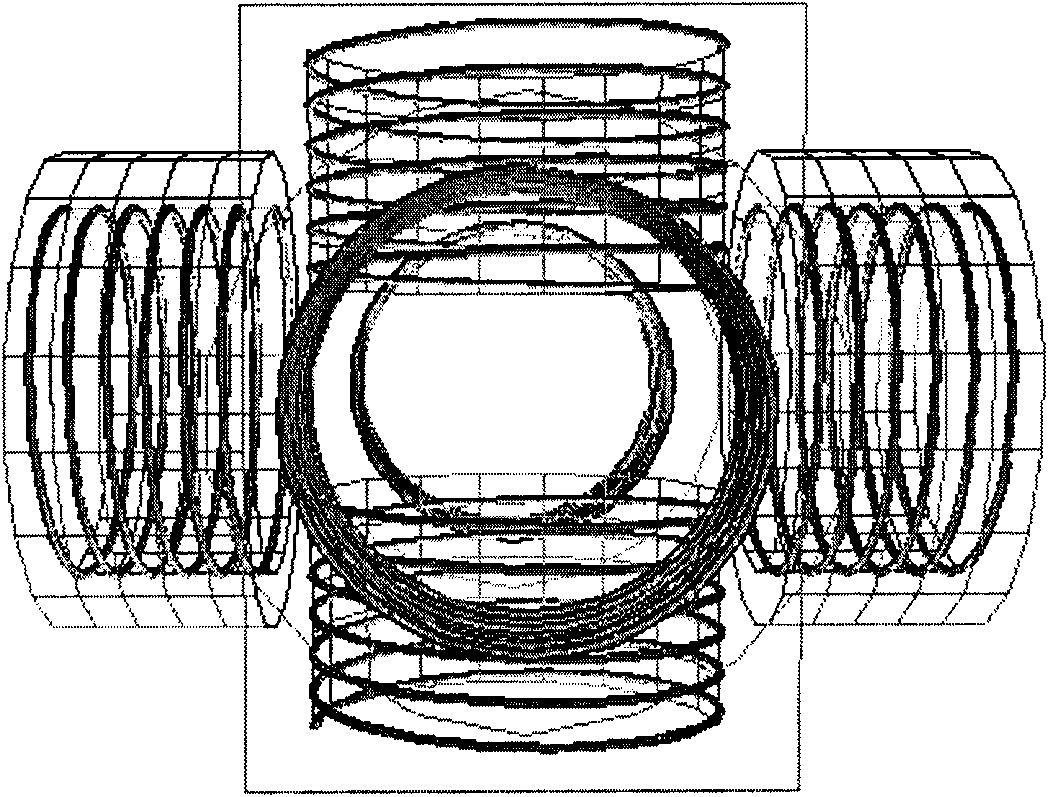

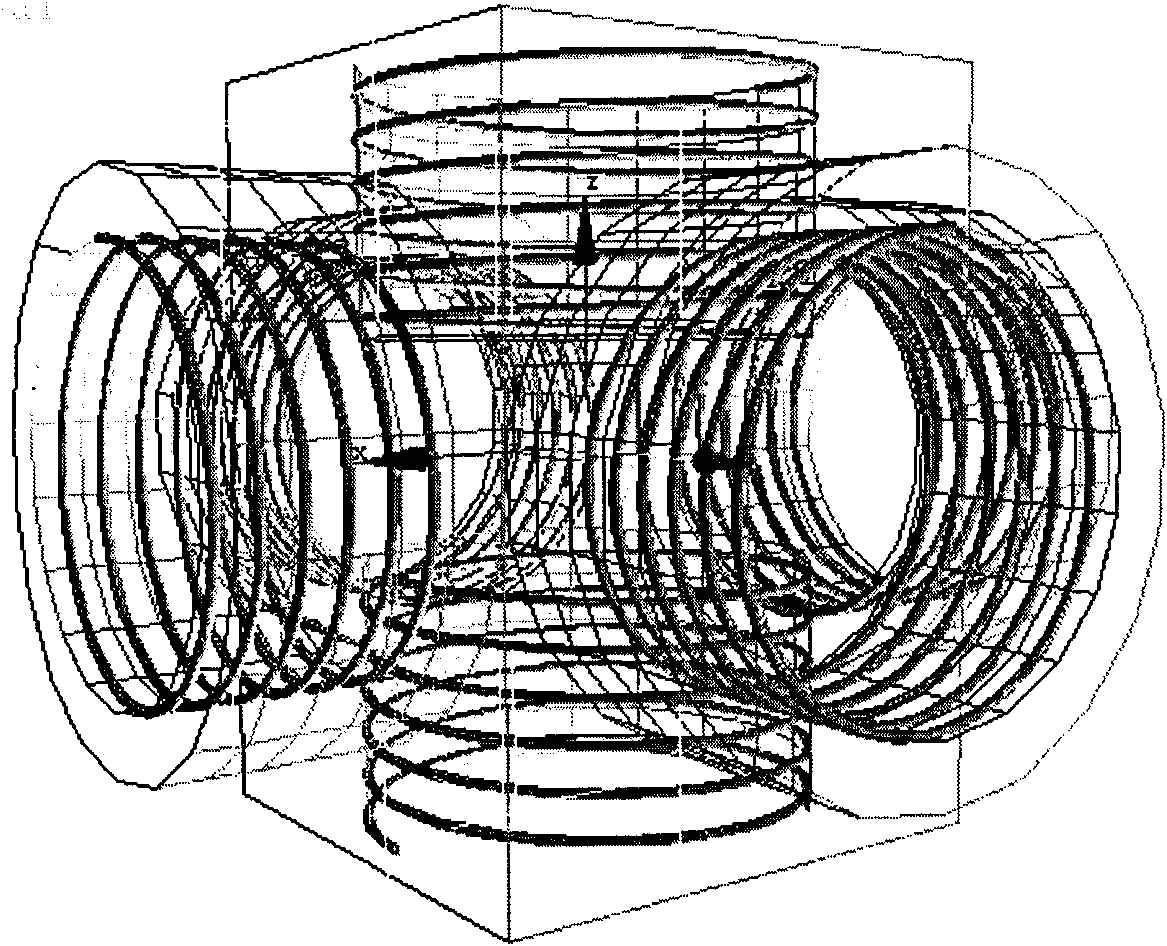

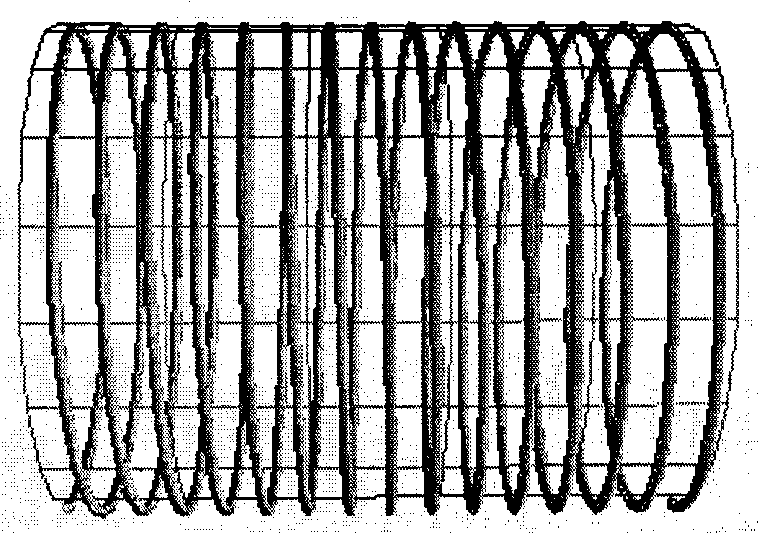

Connector of steel tube

A component and round tube technology, applied in temporary or long-term non-important structural fields, can solve problems such as poor safety and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] First, screw the second part, that is, the force transmission screw cylinder, into the third part (the force cylinder)

[0017] Then; hoist the beam into position aligned with the central tube.

[0018] After that, use a wrench to screw the force transmission helical cylinder into the central circular pipe through the two openings at the end of the stressed circular pipe;

[0019] Finally, after the horizontal columns on the first floor are connected, they are screwed into the vertical columns, so that they can be circulated upwards to form a multi-layer structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com