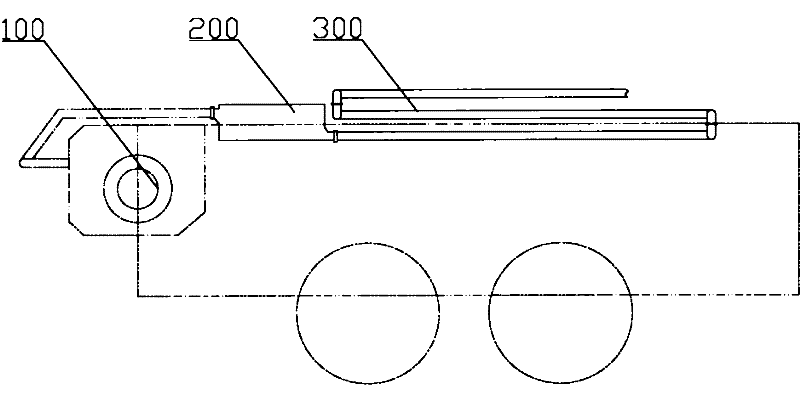

Boom system and pumping machinery

A boom and machinery technology, applied in the field of pumping machinery and boom systems, can solve the problems of limited effect of vibration damping technical solutions and inability to reduce concrete pulses, and achieve turbulent flow mitigation, vibration reduction, and speed stability improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

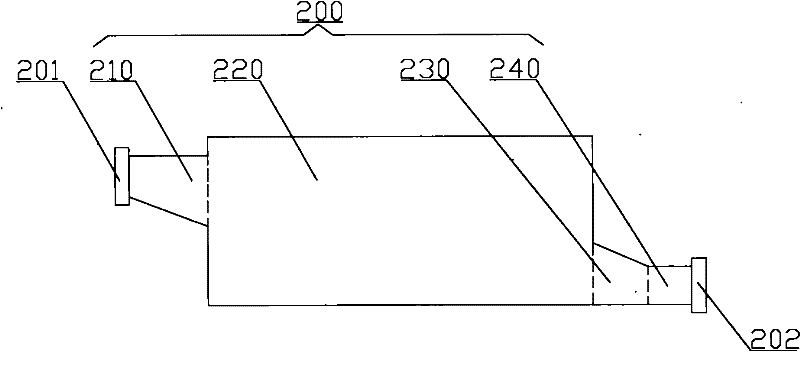

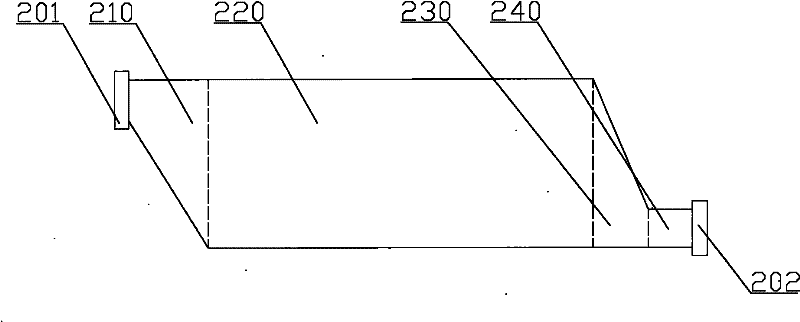

[0026] The present invention will be described in detail below with reference to the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limitation on the protection scope of the present invention. The following takes a concrete pump truck as an example to describe the technical solutions provided by the present invention, but the technical solutions provided by the present invention are not limited to being applied to concrete pump trucks, and can also be applied to pumps for conveying ash, mud and other viscous materials. Sending to the machine.

[0027] The basic core of the present invention lies in: reducing the back pressure of the concrete flow field in an appropriate manner at the appropriate position where the concrete flows through, which can effectively improve the turbulence of the concrete flow field, reduce the amplitude of concrete pulsation, and reduce the vibration of the fluid itself. energy. Based on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com