Spring type parallel bar connector

A parallel rod and connector technology, applied in agricultural machinery, agricultural machinery and implements, mechanical equipment, etc., can solve problems such as reducing field compaction, and achieve the effects of reducing field compaction, convenient installation and manufacturing, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention provides a spring type parallel rod connector.

[0015] The present invention will be described below through embodiments in conjunction with the accompanying drawings.

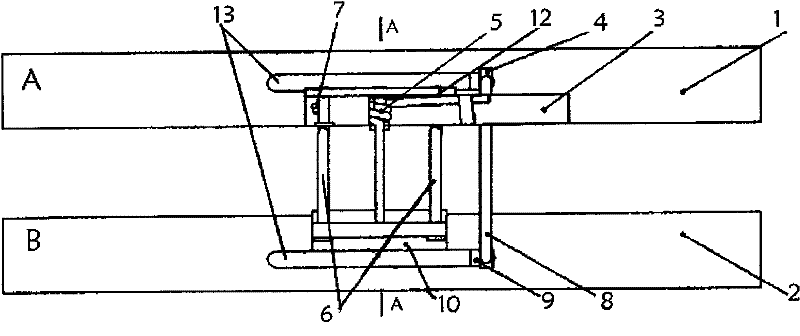

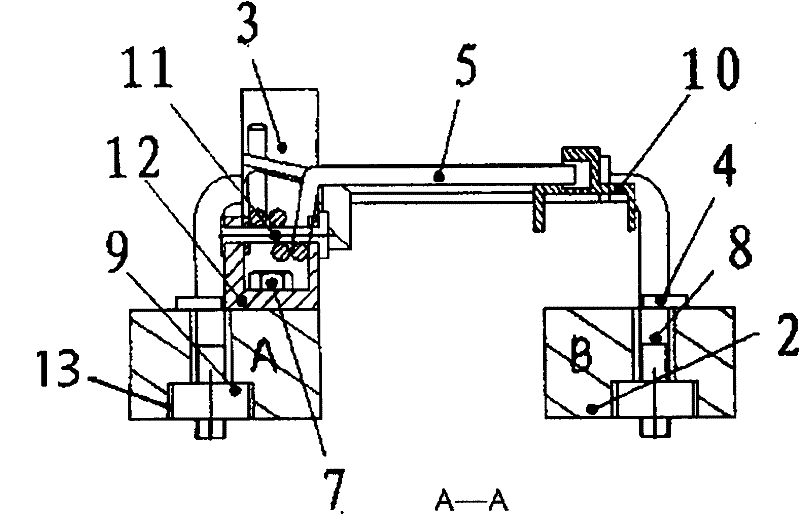

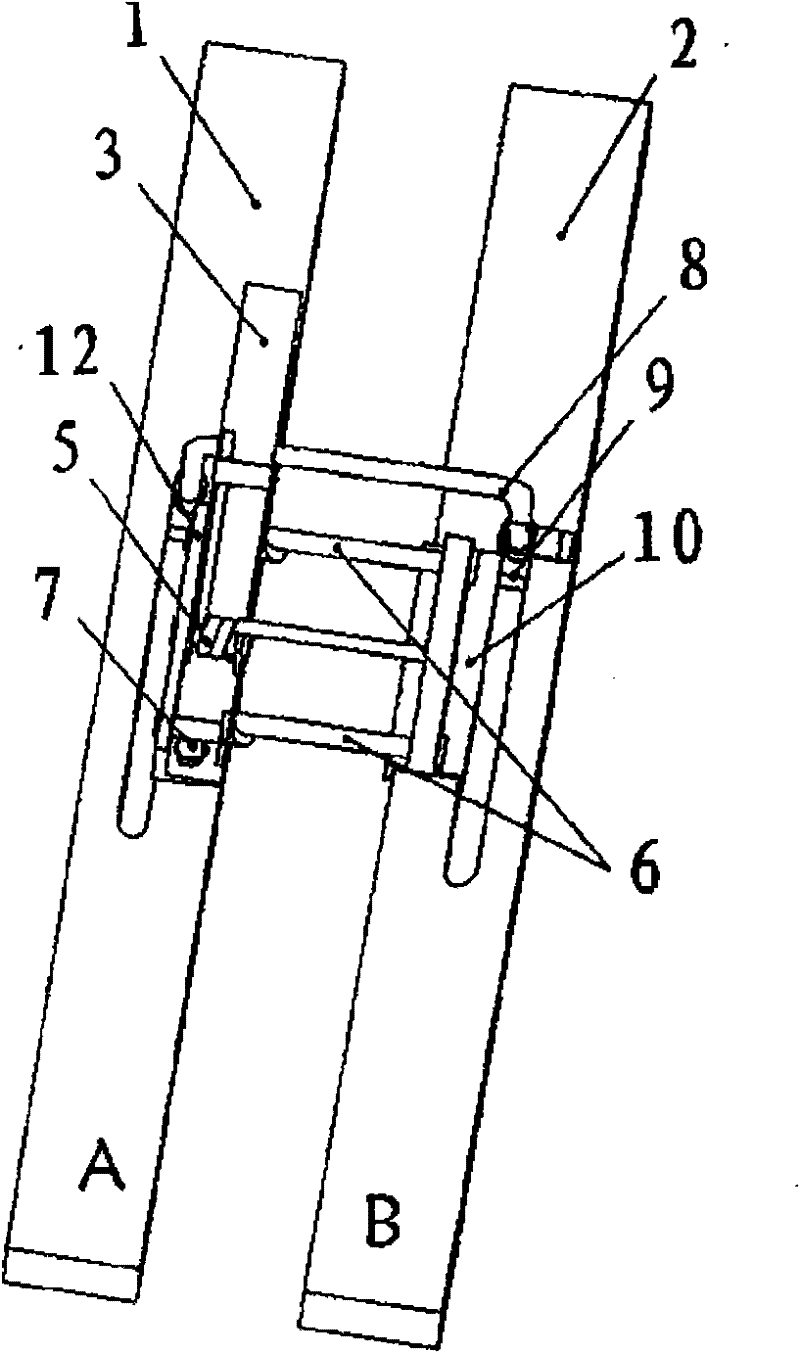

[0016] Such as Figure 1 to Figure 5 As shown, the spring type parallel bar connector is installed on the upper surface and front side of the A frame 1 and B frame 2 of two parallel working tools; The frame 2 has a sliding groove 13, and the spring type parallel rod connector is installed in the sliding groove 13 of the two frames, and is generally used in a complete set, one is installed on the upper surface of the frame, and the other is installed on the side of the frame. The A frame fixed plate 12 is fixed on the A frame 1 by tightening the screw 7, the parallel crank arm bar 6 is put into the locking plate hole on the A frame fixed plate 12, the spring crank arm 5 penetrates in the spring fixed bar 11, and the spring One end of the head is connected with the lock plate 3 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com