Blade-type straw collecting device

A blade-type, grass-collecting technology, which is applied in the field of agricultural machinery, can solve the problems of obstructed connection and many working procedures, and achieve the effect of meeting demand, less energy consumption and less working procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

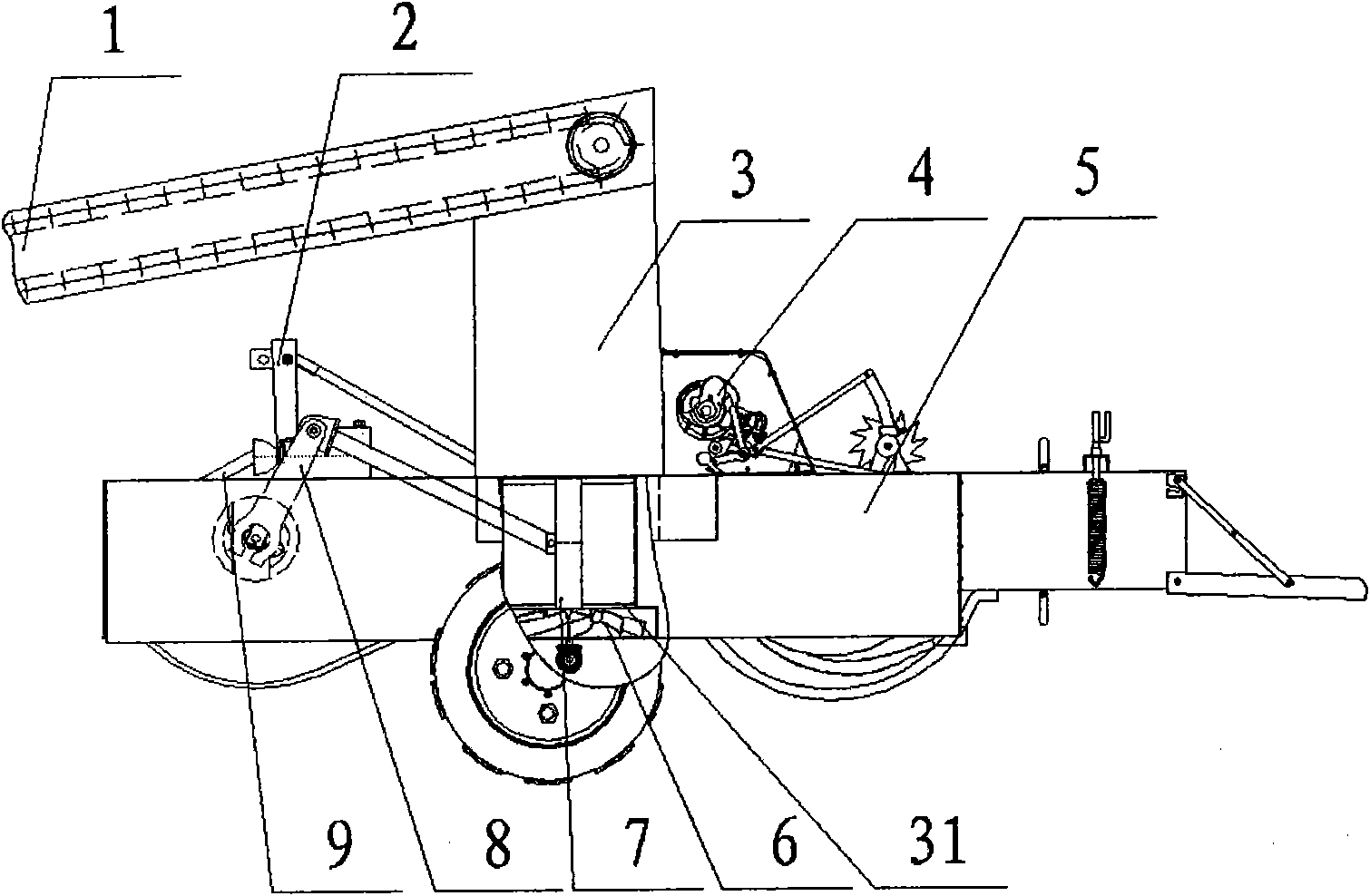

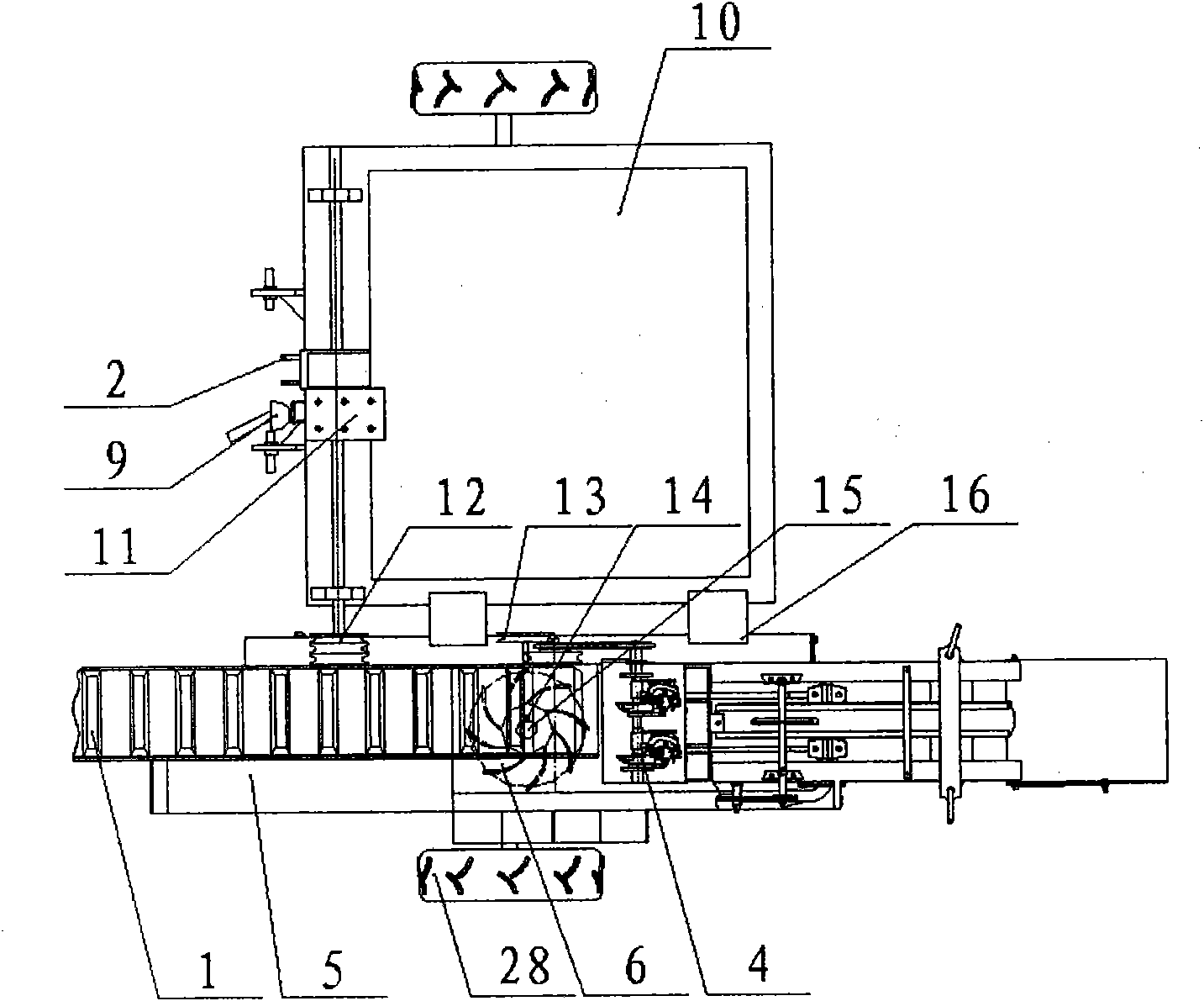

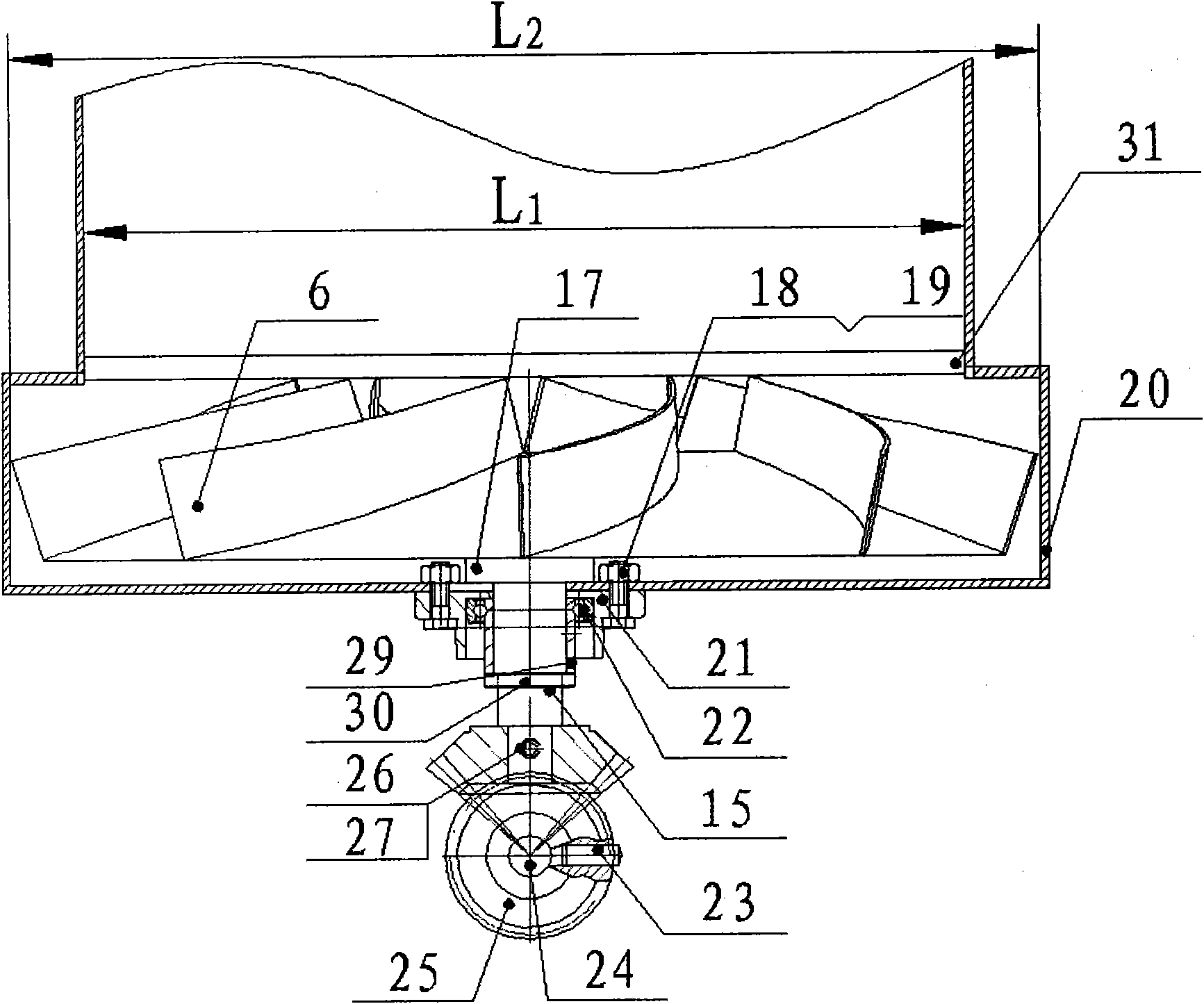

[0014] The present invention provides a blade-type grass collecting device, and the present invention will be described below with reference to the accompanying drawings through embodiments.

[0015] like Figure 1 to Figure 4 As shown, the blade type grass collecting device of the present invention is connected to the baling frame 5 above the ground wheel 28 through the connector 16 and the other work tool frame 10, and is suspended at the rear of the tractor by the three-point suspension frame 2, and the universal joint 9 is connected with the rear power take-off shaft of the tractor. The blade type grass collector 6 is installed in the lower chamber baling chamber wall 20 through the shaft sleeve 17. After aligning the baling plunger 7 on the baling plunger track 31, the upper chamber of the baling chamber is screwed to the upper chamber by using the bolts 18 and 19. On the lower chamber, the grass collector shaft 15 is installed on the bale frame 5 through the outer spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com