Torque measurement device and method

A technology of torque measurement and measurement point, which is applied in the field of torque change measurement devices for detecting rotating machinery during operation, can solve the problems of high installation requirements, large measurement errors and high environmental requirements of photoelectric torque sensors, saving measurement preparation time, The effect of low human influence and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

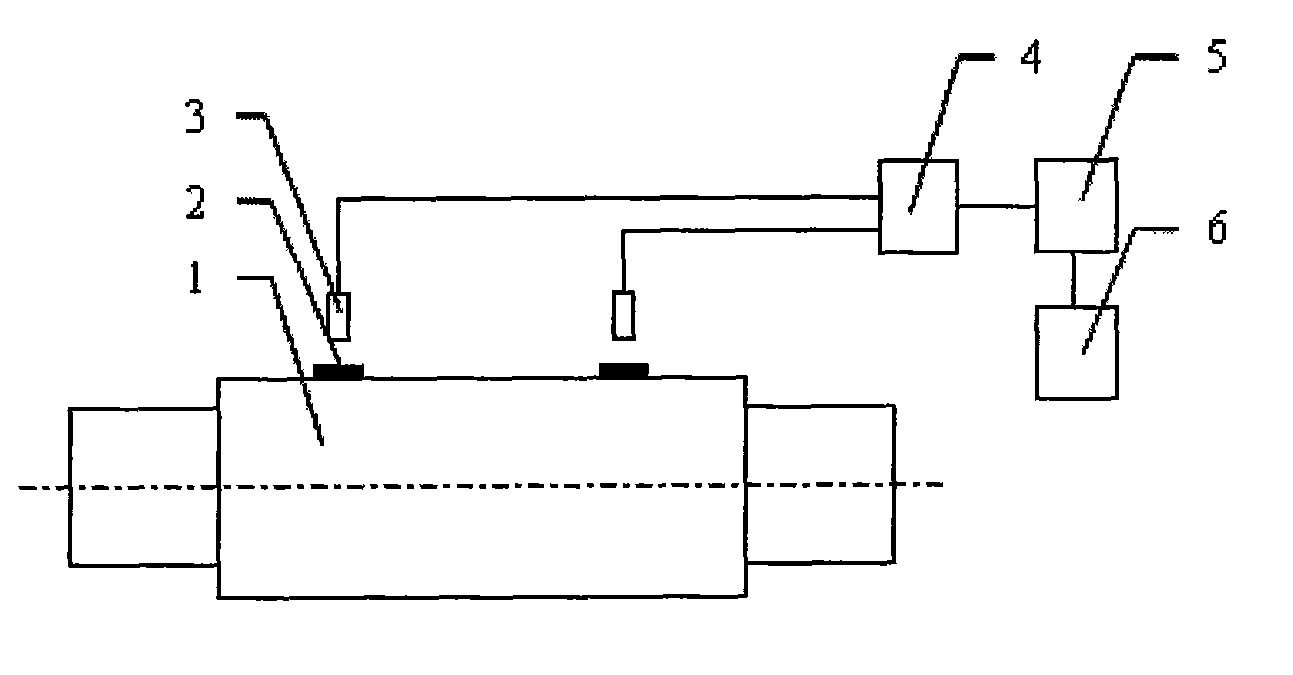

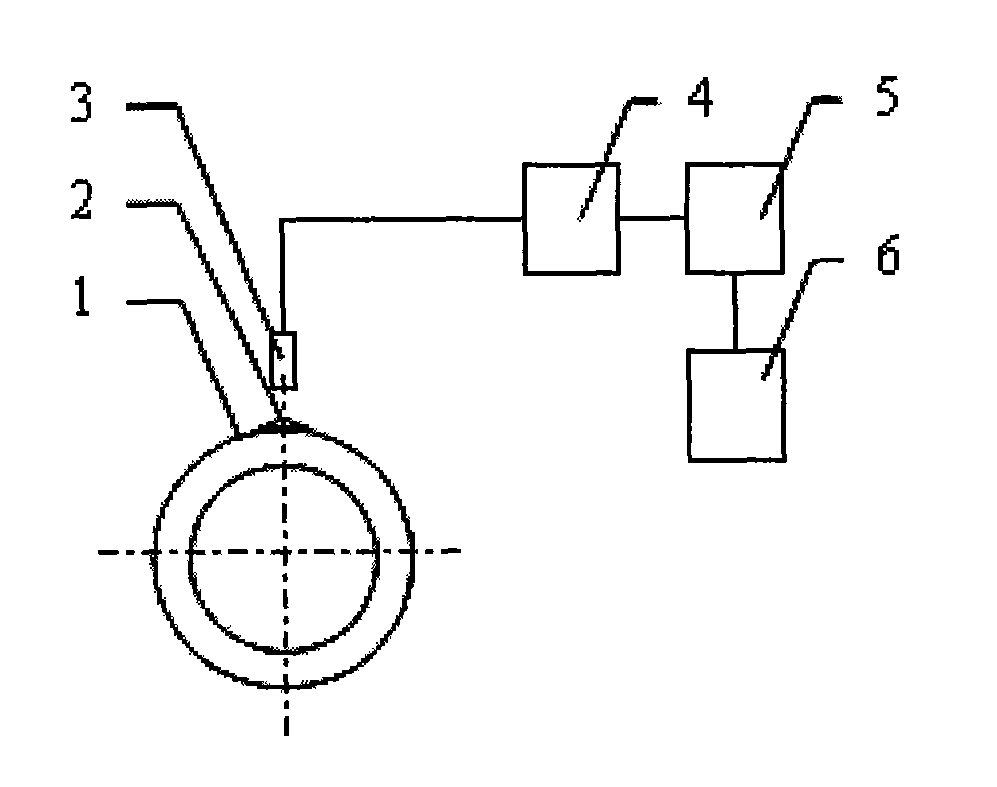

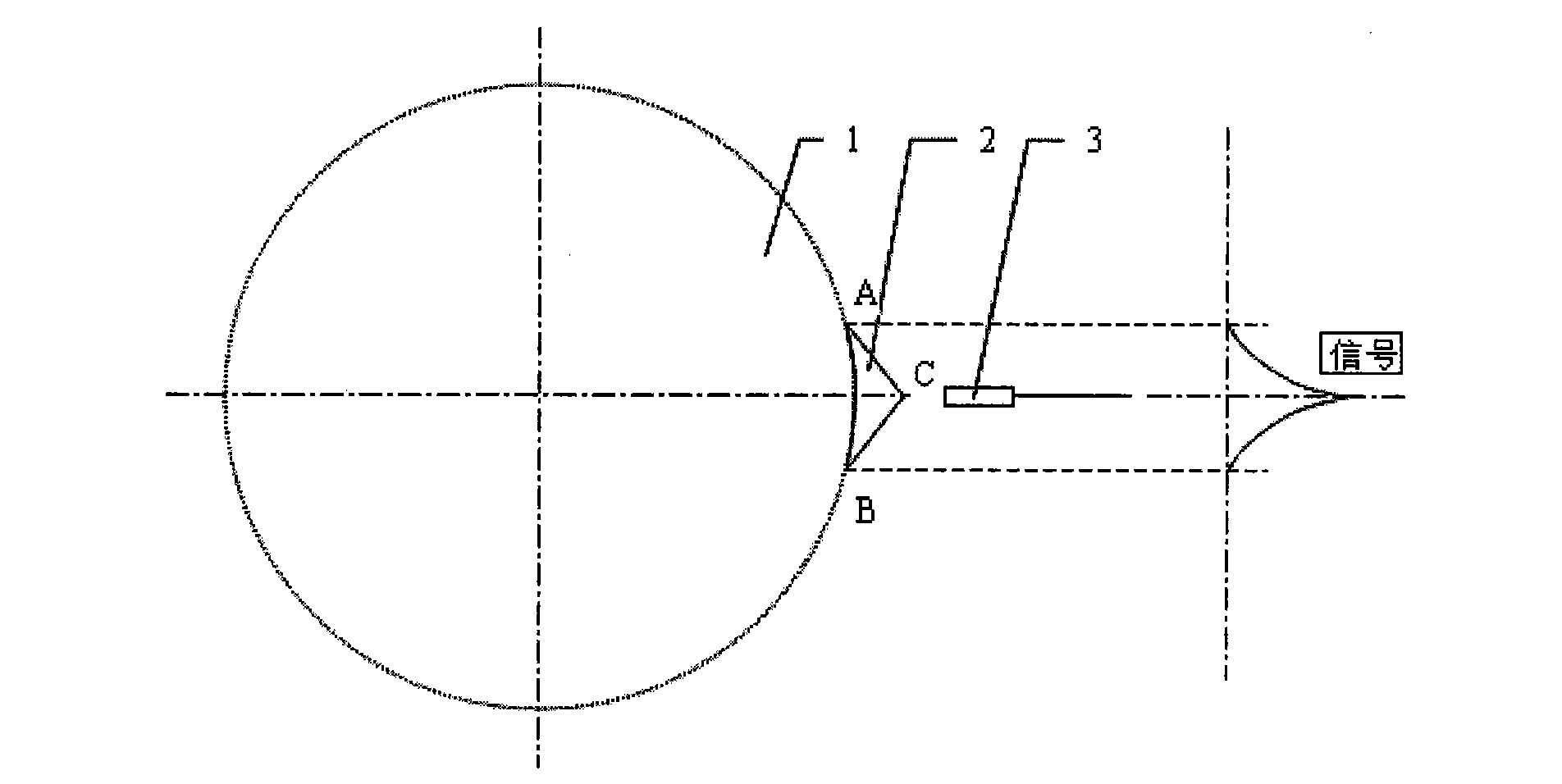

[0031] see figure 1 , 2 As shown, a torque measuring device includes a soft magnet 2, an inductive sensor 3, a signal conditioning module 4, an acquisition module 5 and a computer processing system 6. There are two soft magnets 2, which are respectively arranged on the measured axis 1 On any two measurement points on the circumferential surface, the two measurement points are separated by a certain distance L in the axial direction, and one inductive sensor 3 is fixed to the soft magnetic body 2, and the two inductive sensors 3 pass through the signal conditioning module 4 and the acquisition module 5 synchronously The collected signal is transmitted to the computer processing system 6; the soft magnetic body 2 is a triangular prism whose cross section becomes an isosceles triangle, and the measurement using the device comprises the following steps:

[0032] 1) Select two measuring points, and arbitrarily set two measuring points separated by a certain axial distance on the c...

Embodiment 2

[0061] A torque measuring device, comprising a hard magnet 2, an inductive sensor 3, a signal conditioning module 4, an acquisition module 5 and a computer processing system 6, wherein there are two hard magnets 2, which are respectively arranged on any surface of the circumference of the measured shaft 1 On the two measurement points, the axial distance of the two measurement points is a certain distance L, and an inductive sensor 3 is fixed to the hard magnet 2, and the two inductive sensors 3 are synchronously collected by the signal conditioning module 4 and the acquisition module 5. The signal is transmitted to the computer processing system 6; the hard magnet 2 is a cone, so the apex of the cone is selected as a reference point, which can improve the measurement accuracy.

Embodiment 3

[0063] A torque measuring device, comprising a hard magnet 2, an inductive sensor 3, a signal conditioning module 4, an acquisition module 5 and a computer processing system 6, wherein there are two hard magnets 2, which are respectively arranged on any surface of the circumference of the measured shaft 1 On the two measurement points, the axial distance of the two measurement points is a certain distance L, and an inductive sensor 3 is fixed to the hard magnet 2, and the two inductive sensors 3 are synchronously collected by the signal conditioning module 4 and the acquisition module 5. The signal is transmitted to the computer processing system 6; the hard magnet 2 is a cylinder, and the endpoints on both sides of the cylinder are selected as reference points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com