Machine for husking to get kernel of hickory nut (husk and kernel separation)

A technology for walnut kernels and pecans, which is applied in the field of pecan peeling and kernel extracting machines, can solve the problems of different pecan kernels in quality, irregular shape, time-consuming and labor-intensive, etc., and achieves low crushing rate, uniform force and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

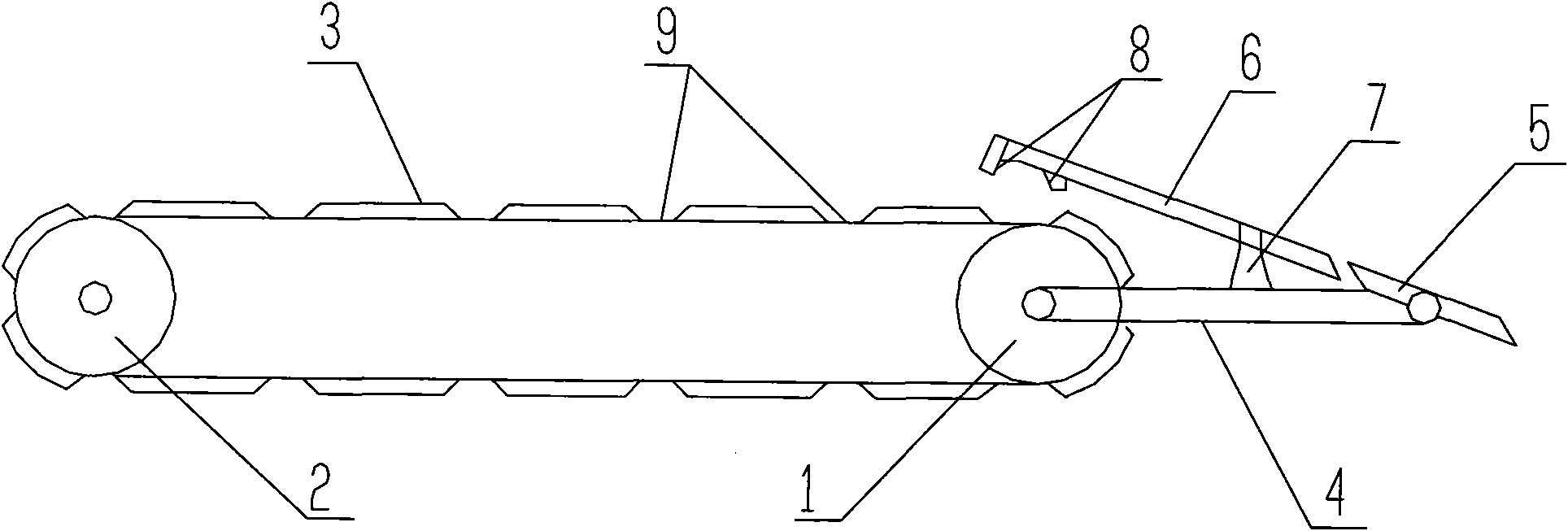

[0011] Such as figure 1 Shown, provided an embodiment of hickory nut shelling and getting kernel (shell kernel separation) machine of the present invention, it comprises driving sprocket 1, gear 2, crawler arrangement along driving sprocket 1 and gear 2 operation Belt 3, the push rod 5 that links to each other with driving sprocket 1 by drive chain 4, the power arm 6 that links to each other with push rod 5 and the spring bar seat 7 that is positioned at transmission chain 4 and supports power arm 6, the power arm 6 The end is equipped with shelling cutter (upper cutter) 8, and a plurality of shelling cutters (lower cutter) 9 corresponding to shelling cutter (upper cutter) 8 are evenly equipped with on the described crawler type arrangement belt 3. During work, the motor drives the drive sprocket 1, so that the crawler arrangement belt 3 runs along the drive sprocket 1 and the gear 2, and the hickory nuts output in the feeding hopper are arranged on the shelling cutter (lower ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap