Full-automatic hydraulic plate pulling mechanism of filter press

A filter press, fully automatic technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems that the filter plate cannot be automatically and stably pulled apart, the labor intensity is high, the motor starting current is large, etc., and the artificial Low labor intensity, high drawing efficiency and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

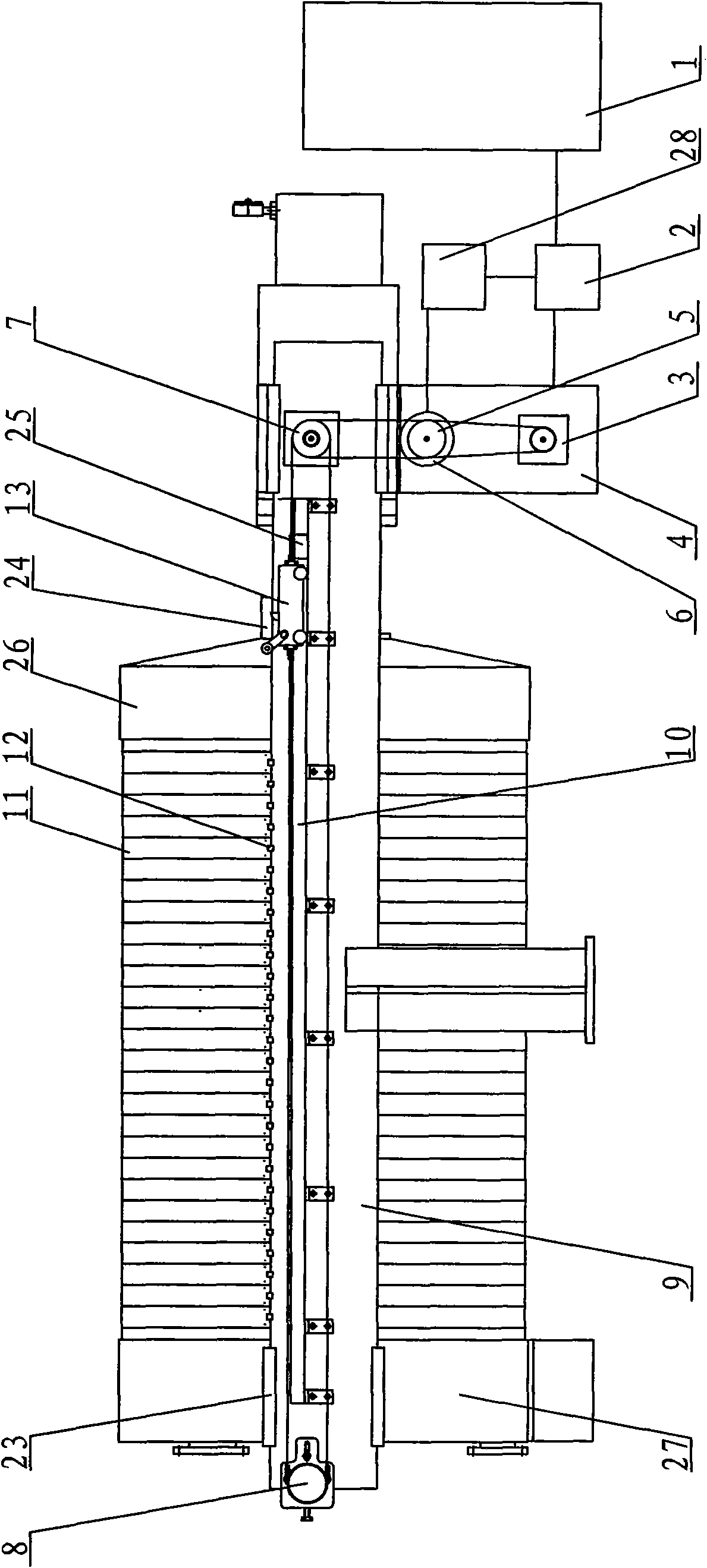

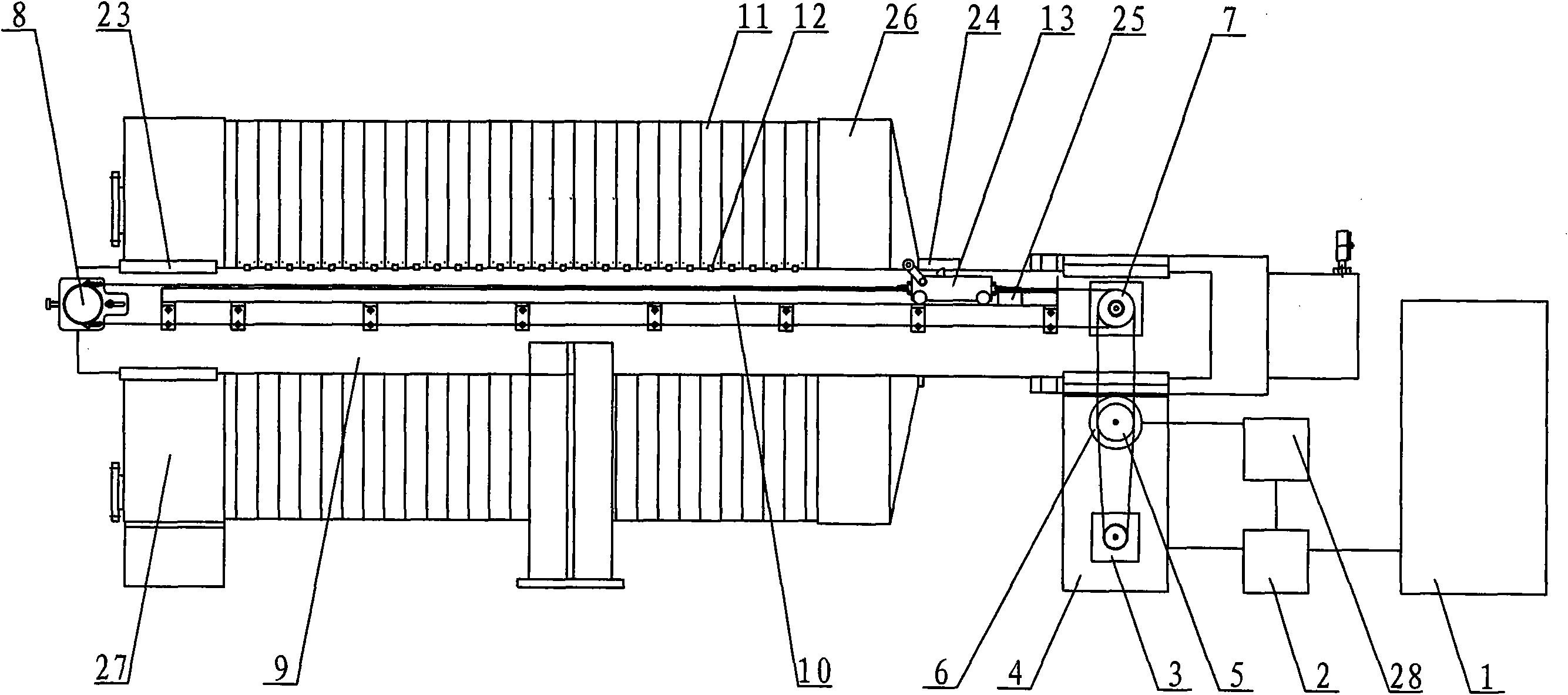

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

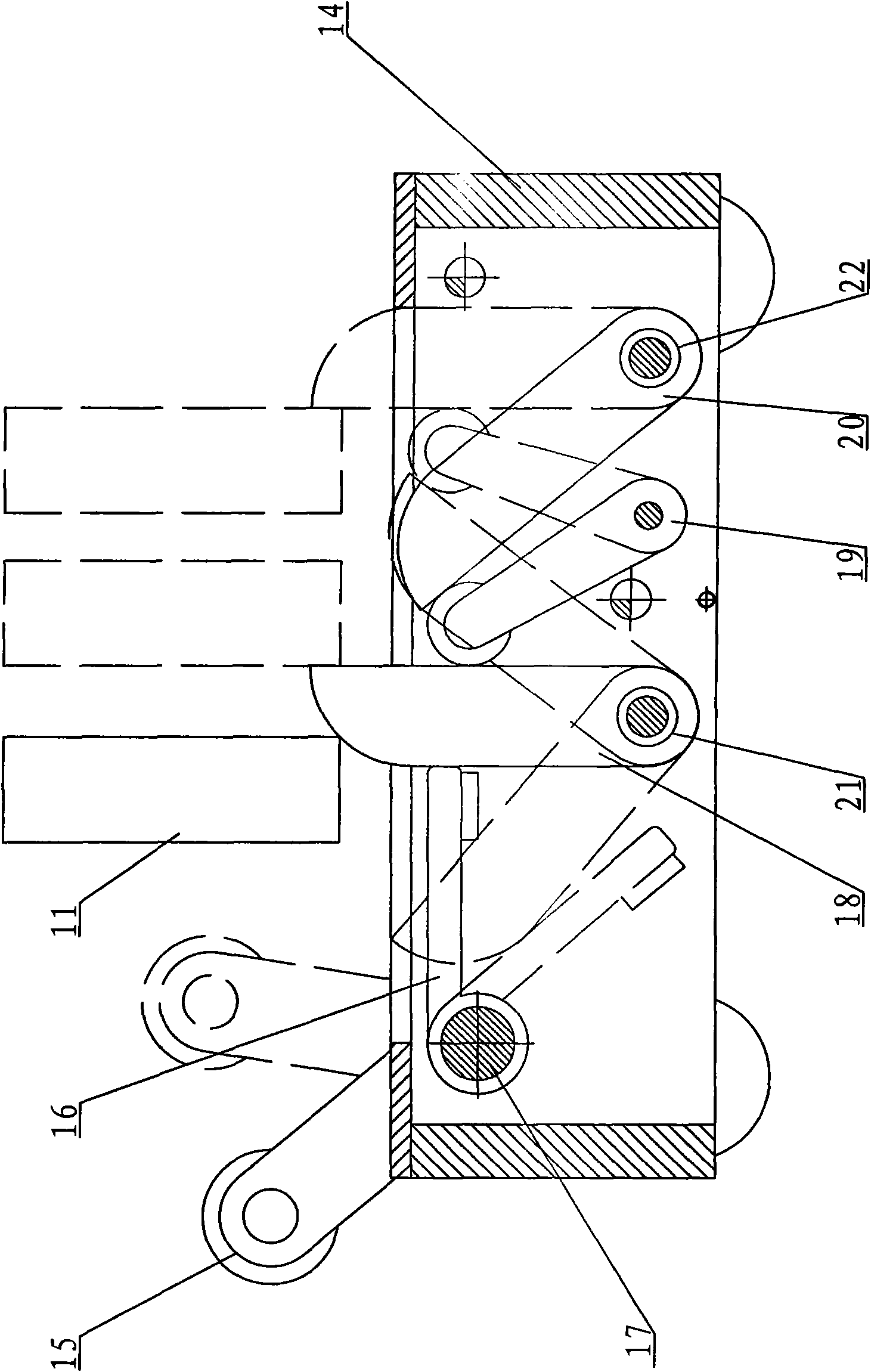

[0013] figure 1 As shown, the fully automatic hydraulic plate pulling mechanism of the filter press includes a main beam 9 , a filter plate group 11 , a plate pulling device 13 , an oil motor 3 and a hydraulic station 1 . The two ends of the main beam 9 are respectively supported on the fixed end support 27 and the oil cylinder assembly support 4, the movable platen 26 is slidably supported on the main beam 9, and a filter plate group is arranged between the movable platen and the fixed end support. Each filter plate 11 is slidably supported on the main beam 9 through the hanging lugs 12 on both sides of the filter plate. The main beam 9 is provided with a track 10, and the track at the end of the fixed end bracket 27 is provided with a reset block 23. The track at the end is provided with a reset block 24 and a travel switch 25; the lower part of the oil cylinder asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com