Wall-mounted waterworks moss cleaning machine

A waterworks, wall-mounted technology, applied in the field of cleaning machines, can solve the problems of waterworks economic and reputation loss, the inability to improve the quality of tap water, and low work efficiency, so as to improve the quality of tap water, improve social status, and avoid the danger of work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

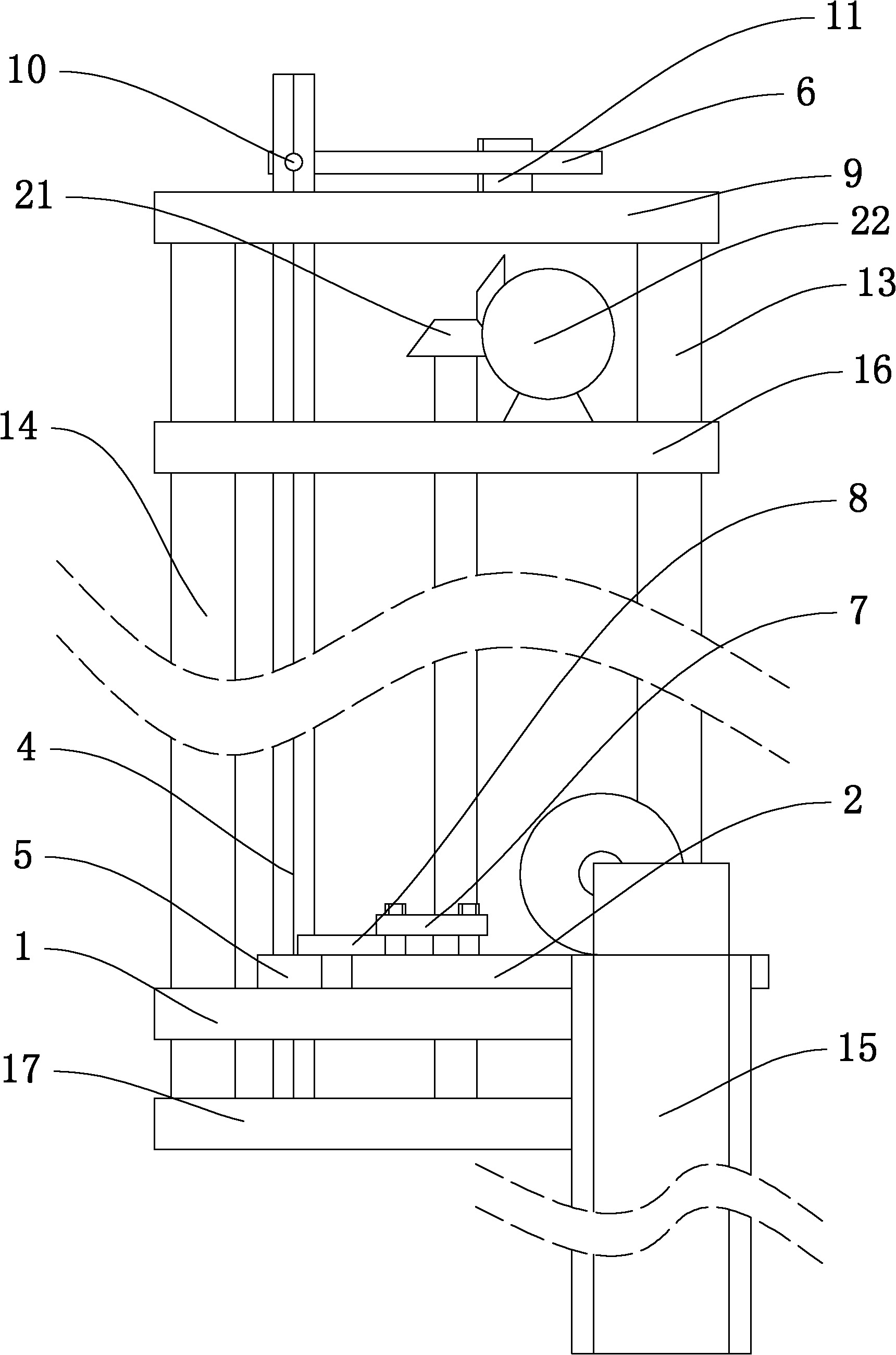

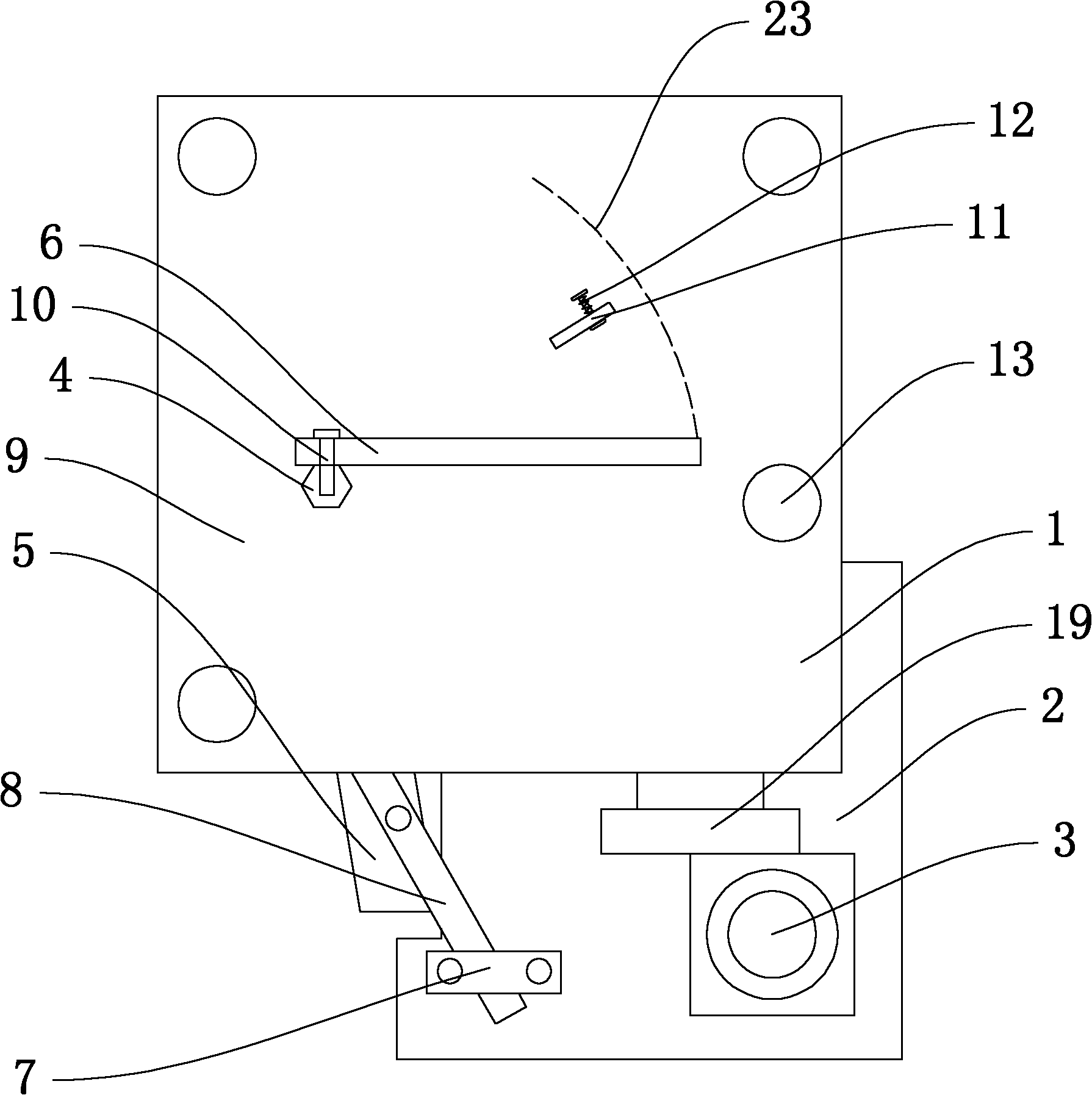

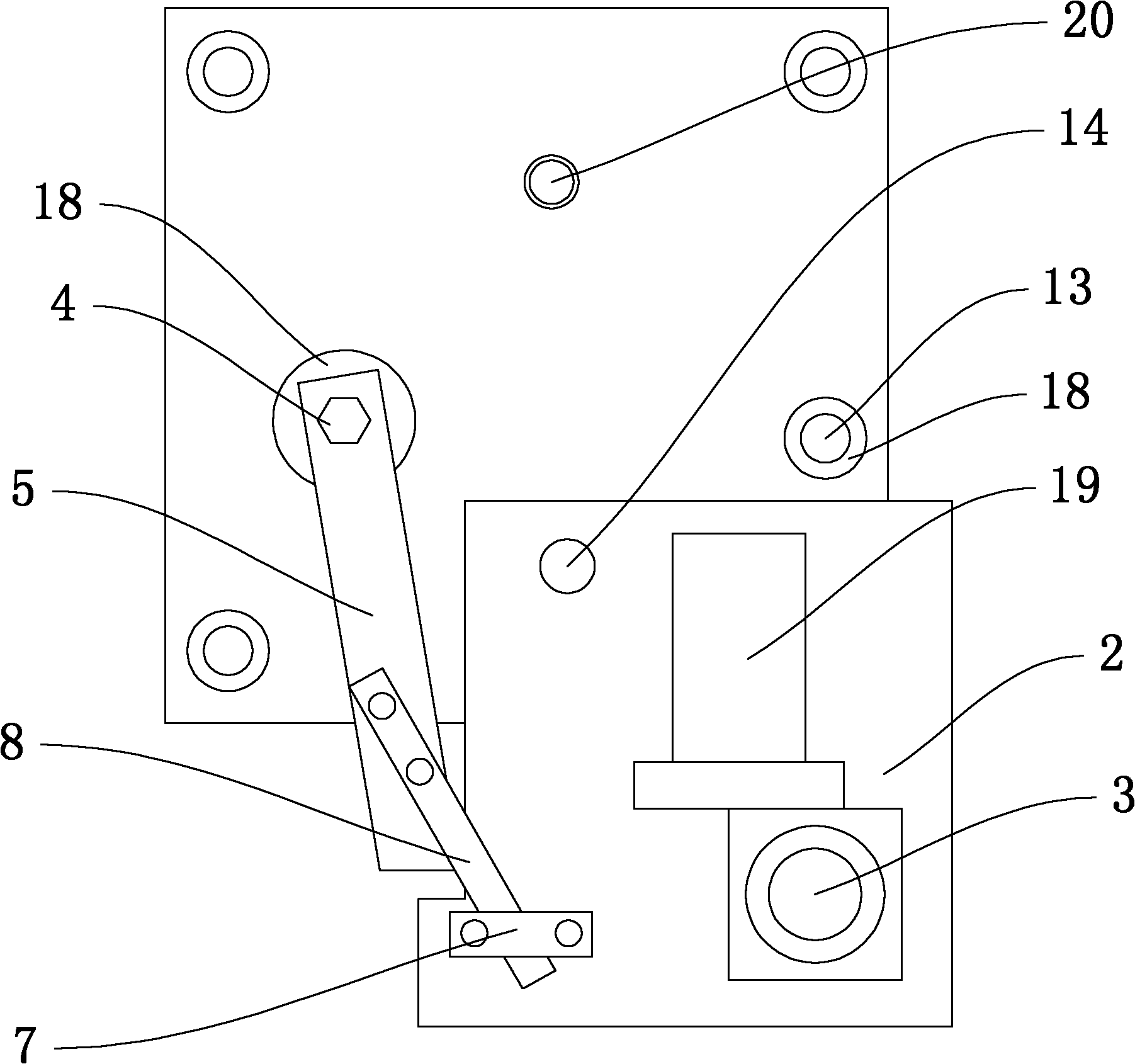

[0017] Such as figure 1 , figure 2 , image 3 Shown, the designed wall-mounted waterworks moss cleaning machine of the present invention designed by the present invention mainly comprises a wall mount 14, a roller brush 15, and the wall mount 14 consists of an upper top plate 16, a lower base plate 17 and is arranged between the two Composed of pillars 13, a lifting platform 1 is provided between the upper top plate 16 and the lower bottom plate 17. The lifting platform 1 forms a sliding pair between the sliding bearing 18 and the pillar 13, and a swing platform is provided on the lifting platform 1 through a hinge connection 13. 2. A part of the swing platform 2 extends outside the wall hanger 14. A roller brush drive motor 19 is fixed on the swing platform 2. The roller brush drive motor 19 is connected to the roller brush 15 through the roller brush transmission mechanism 3, and the roller brush 15 is oscillated by The lower part of the platform 2 is inserted upwards and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com