Sheet feeding unit and image forming apparatus

A sheet material feeding technology, which is applied in the field of electrophotographic copiers, sheet material feeding equipment and image forming equipment, can solve the problems of not being able to obtain the adsorption force of the sheet material, and cannot apply small alternating charges, etc., and achieve reduction The effect of small charged distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

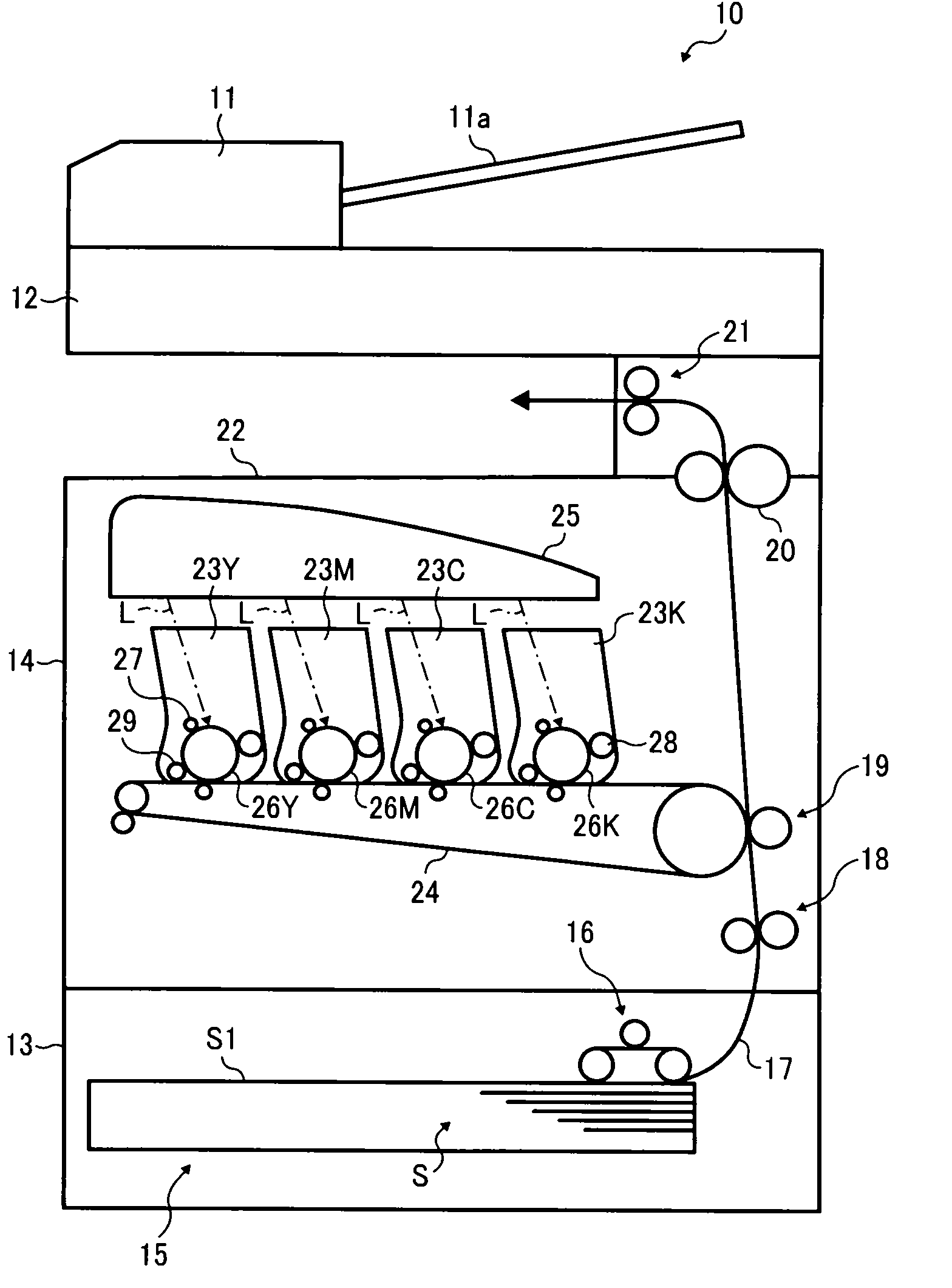

[0084] Figure 1 to Figure 13 Shown is a first embodiment of the sheet feeding device and the image forming device according to the present invention, and the image forming device will be described by taking an electrophotographic copier as an example.

[0085] First, its configuration will be described.

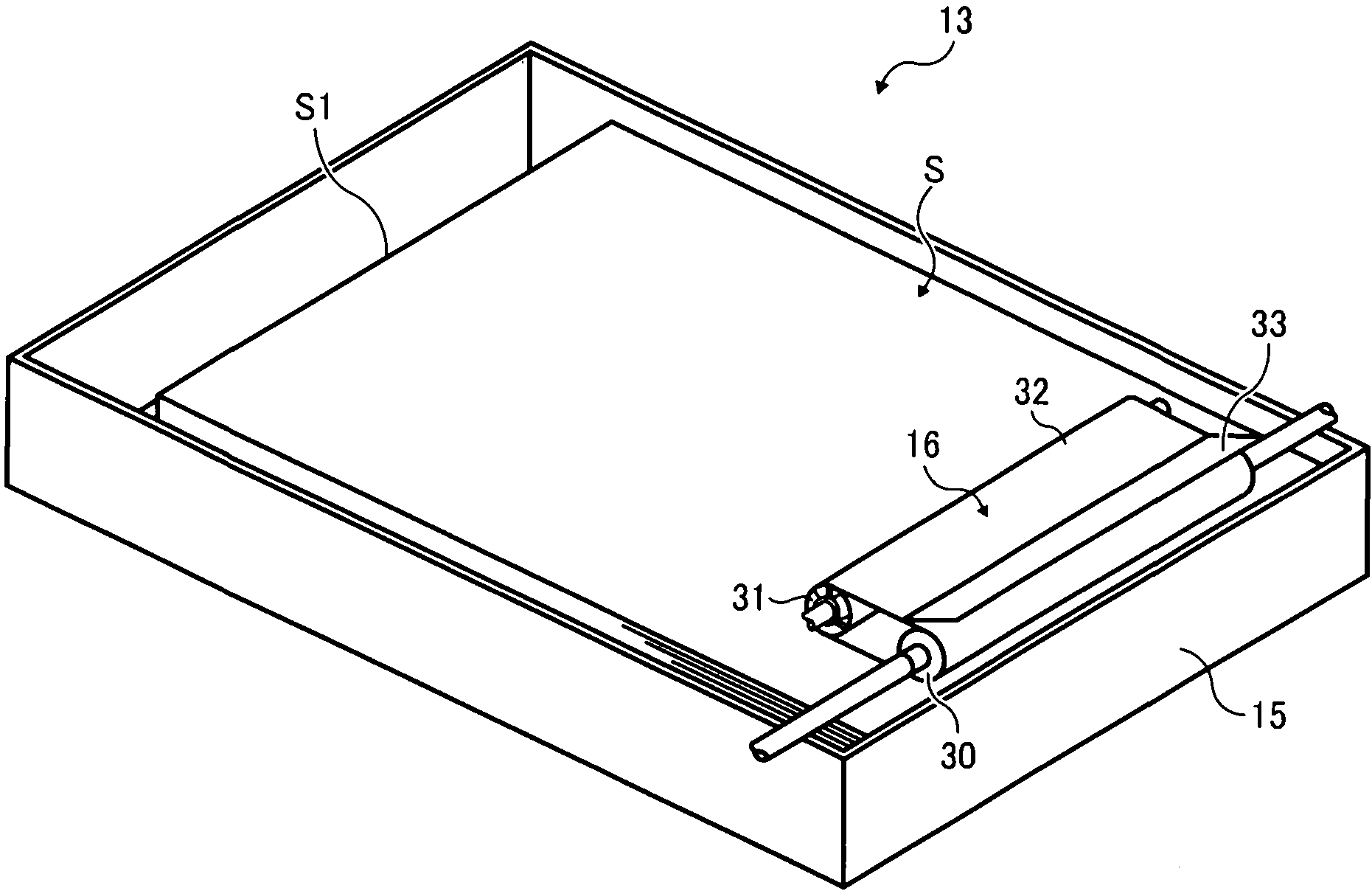

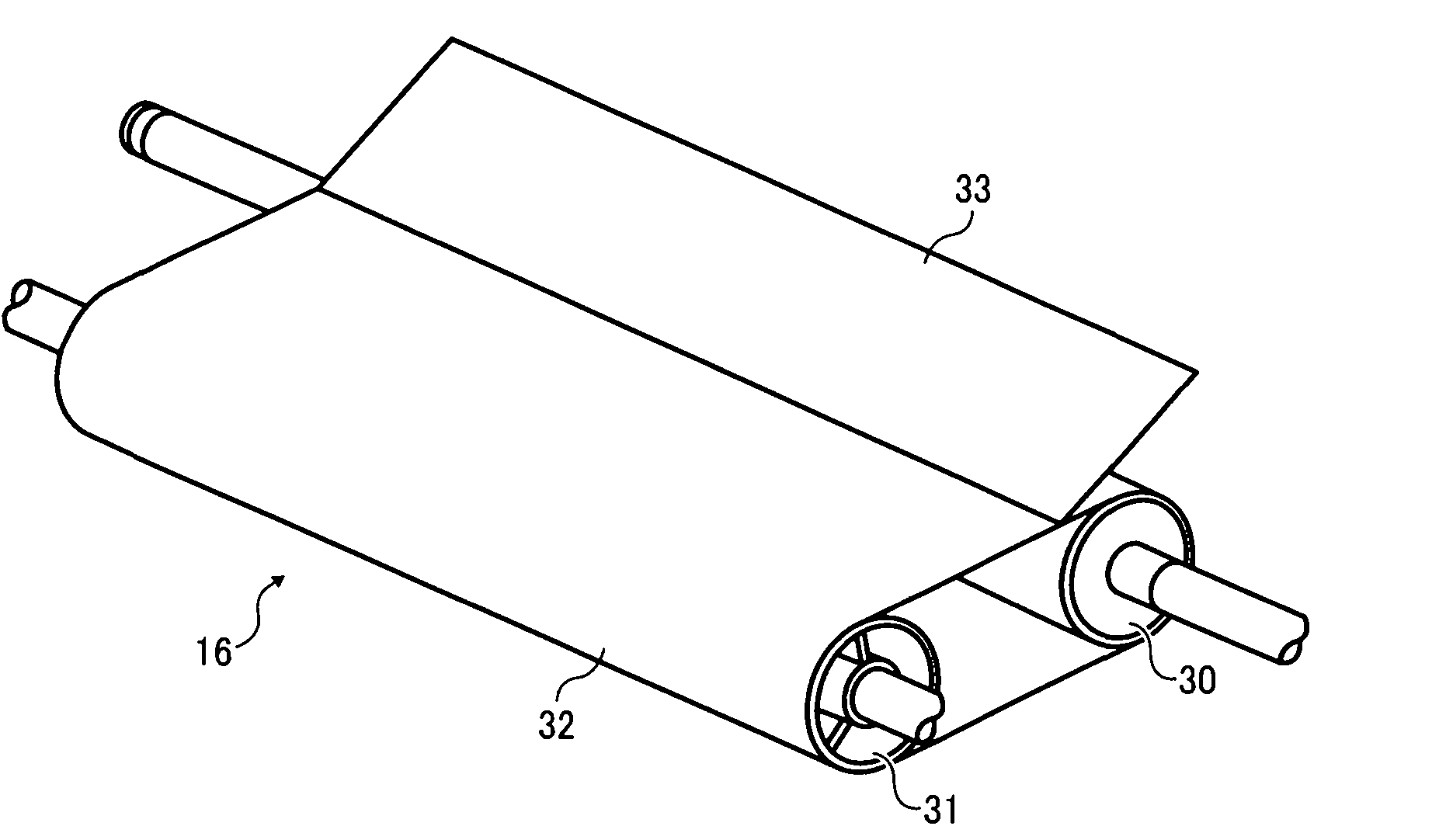

[0086] exist figure 1 Among them, the copying machine 10 as an image forming device includes an automatic document conveyance device that separates original documents one by one from the original document bundle placed in the original document tray 11a and automatically feeds them into the contact glass of the original document reading section 12. 11; the document reading part 12 that reads the document conveyed onto the contact glass by the automatic document conveying device 11; The image forming section (image forming apparatus) 14 of the captured image; has a sheet bundle S on which a plurality of sheets are placed, and feeds S1 located at the top of the sheet bundle ...

no. 2 Embodiment approach

[0151] Figure 14 , Figure 15 Shown is the second embodiment of the sheet feeding device and the image forming device according to the present invention. In this embodiment, a charging roller is used as a conductive member instead of the charging blade in the first embodiment. The same symbols are assigned to the same configurations in the embodiments, and description thereof will be omitted.

[0152] exist Figure 14 , Figure 15 Among them, the charging roller 71 as a charging member has an outer peripheral portion 71 a that forms a nip portion together with the endless belt 32 after being in contact with the endless belt 32 , and this outer peripheral portion 71 a constitutes a contact portion. In addition, the width|variety of a nipping part is called nipping width N hereafter.

[0153] Additionally, if Figure 15As shown, the charging roller 71 has the effect of forming a discharge that applies charges to the surface of the endless belt 32 by discharging between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com