Two-freedom-degree regulation self-leveling spreader and regulation method

A degree of freedom and horizontal technology, applied in the field of machinery, can solve the problems of high operator proficiency requirements, increased operational risks and safety hazards, and failure to achieve installation surface leveling, etc., to achieve simple and effective operation, overcome operational risks and safety hidden danger, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

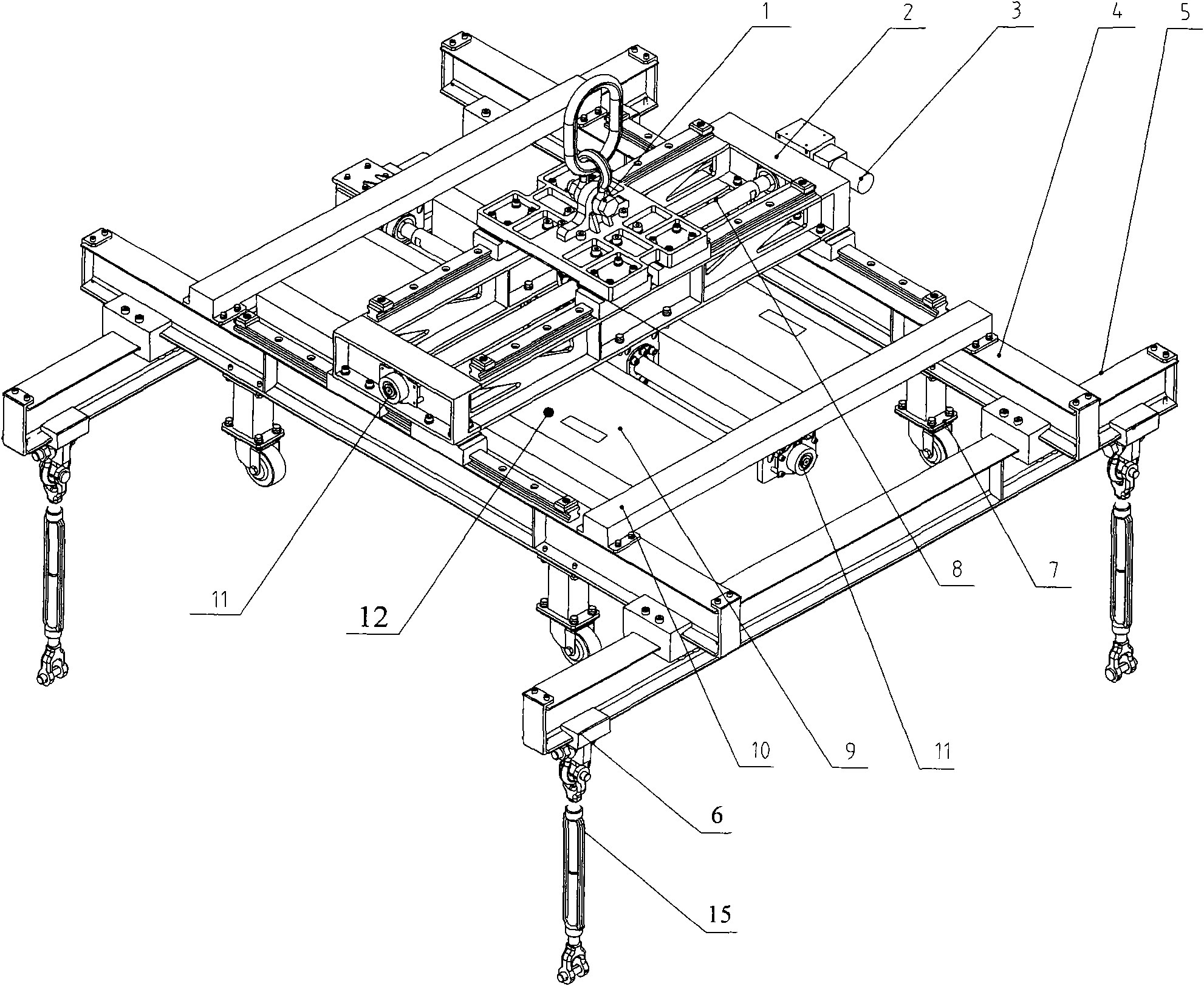

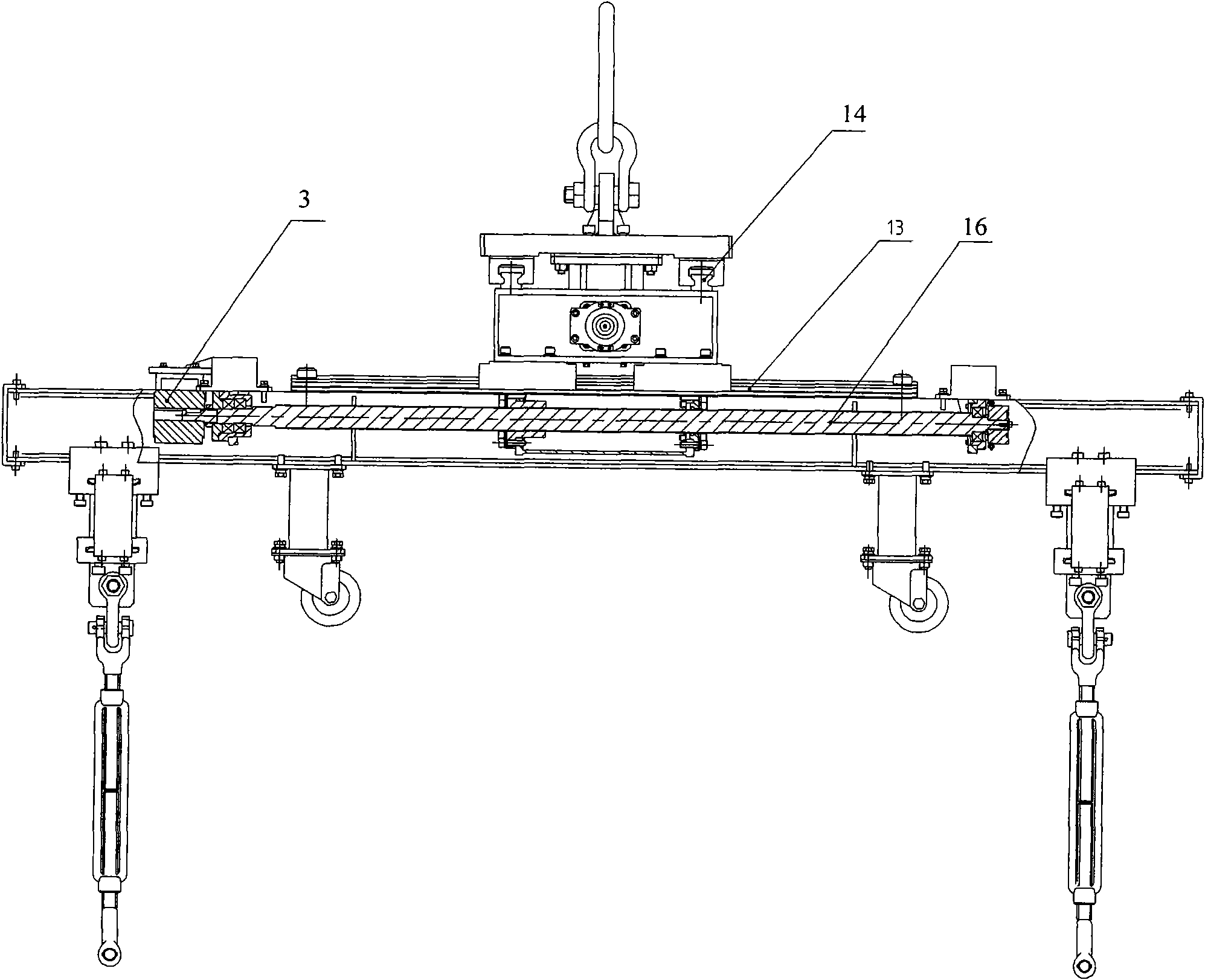

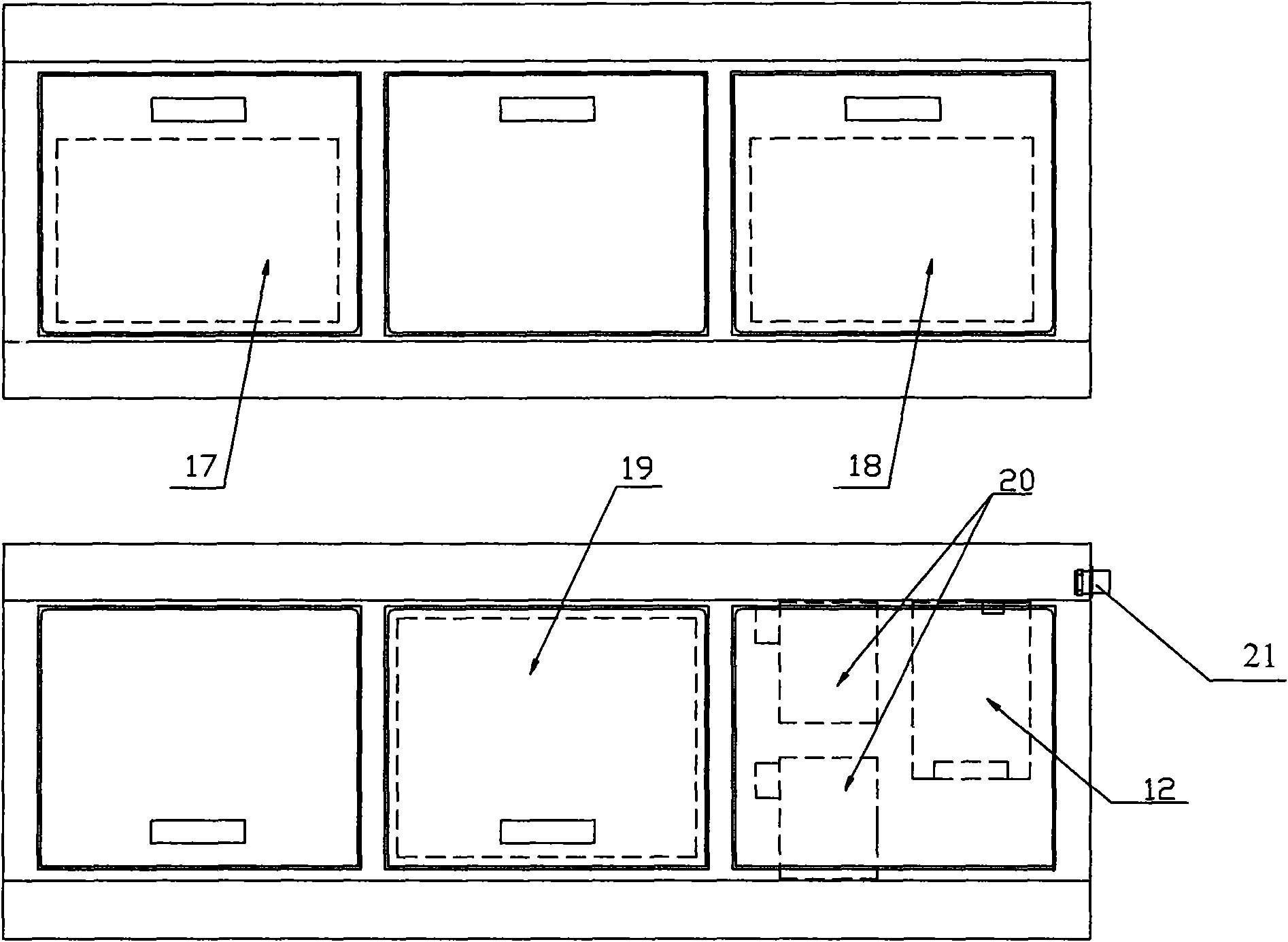

[0031] like figure 1 and figure 2 Shown, the present invention comprises main hanging slider 1, sliding frame 2, two DC motors 3, two fixed beams 4, two adjusting beams 5, four suspension sliders 6, four mobile supporting wheels (7), The first ball screw pair 8, the second ball screw pair 16, the control cabinet 9, two connecting beams 10, the inclination sensor 12, the first group of linear guides 13, the second group of linear guides 14 and four turnbuckle screws 15;

[0032] The two fixed beams 4 and the two adjustable beams 5 are connected in a well shape by bolts, the adjustable beams 5 can move along the fixed beams 4 through the dovetail connectors, and the two ends of the connecting beam 10 are respectively installed above the two fixed beams 4 by bolts , used to strengthen the structure and provide an installation interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com